Silent lock

A silent lock and lock tongue technology, applied in the field of locks, can solve the problems of contact collision, collision and friction between the lock tongue and the lock plate, and achieve the effect of improving safety, reducing repeated actions, and preventing forgetting to lock the lock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

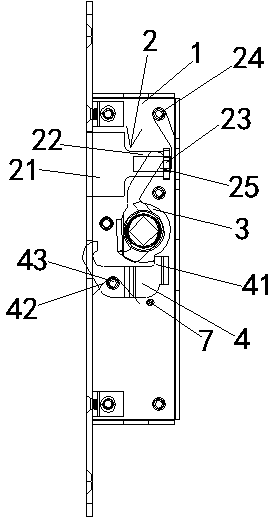

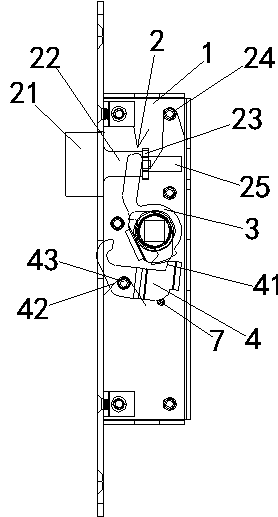

[0037] figure 1 It is a schematic structural diagram of the silent lock in the unlocked state according to this embodiment; figure 2 It is a structural schematic diagram of the silent lock in the locked state according to this embodiment.

[0038] This embodiment describes a silent lock, including a lock body and a lock plate, wherein the lock plate (not shown in the figure) is fixed on the door frame or window frame, and a cavity is opened on the lock plate. The structure of the lock plate can be Choosing a conventional structure is not the main point of the present invention, and will not be repeated here.

[0039] Such as figure 1 , figure 2 As shown, the lock body includes a lock box 1, a lock tongue assembly 2, a toggle block 3 and a handle (not shown in the figure). The lock tongue assembly 2 and the toggle block 3 are both located in the lock box 1, and the handle passes The square shaft drives the toggle block 3 to rotate, and the toggle block 3 then drives the lock tongu...

Embodiment 2

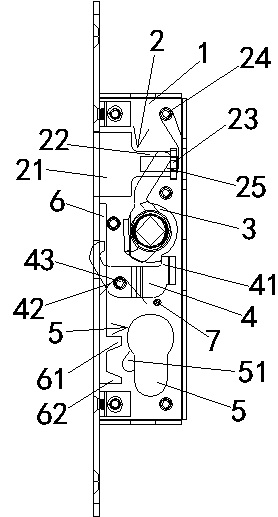

[0046] image 3 It is a schematic structural diagram of the silent lock according to this embodiment in an unlocked state, wherein a locking mechanism is provided in the lock box; Figure 4 It is a schematic structural diagram of the silent lock in the locked state according to this embodiment, in which a locking mechanism is provided in the lock box.

[0047] The main structure of the multiple silent lock described in this embodiment is basically the same as the silent lock structure described in the first embodiment. In this embodiment, the lock body is also provided with a locking mechanism 5 for locking the bolt 21. Such as image 3 , Figure 4 The locking mechanism 5 shown includes a shifting block 51, a shifting block driving mechanism 52, and a locking block 6. The shifting block driving mechanism 52 is driven by an external device, and the shifting block 51 follows the actions of the shifting block driving mechanism 52. While rotating, the shifting block 51 drives the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com