A flame retardant fireproof high temperature resistant polyethylene film laying device

A high-temperature-resistant polyethylene and laying device technology, which is applied in roads, buildings, road repairs, etc., can solve the problems of low laying efficiency, time-consuming and labor-intensive film laying, and achieve the effects of reducing labor intensity, improving efficiency, and avoiding skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

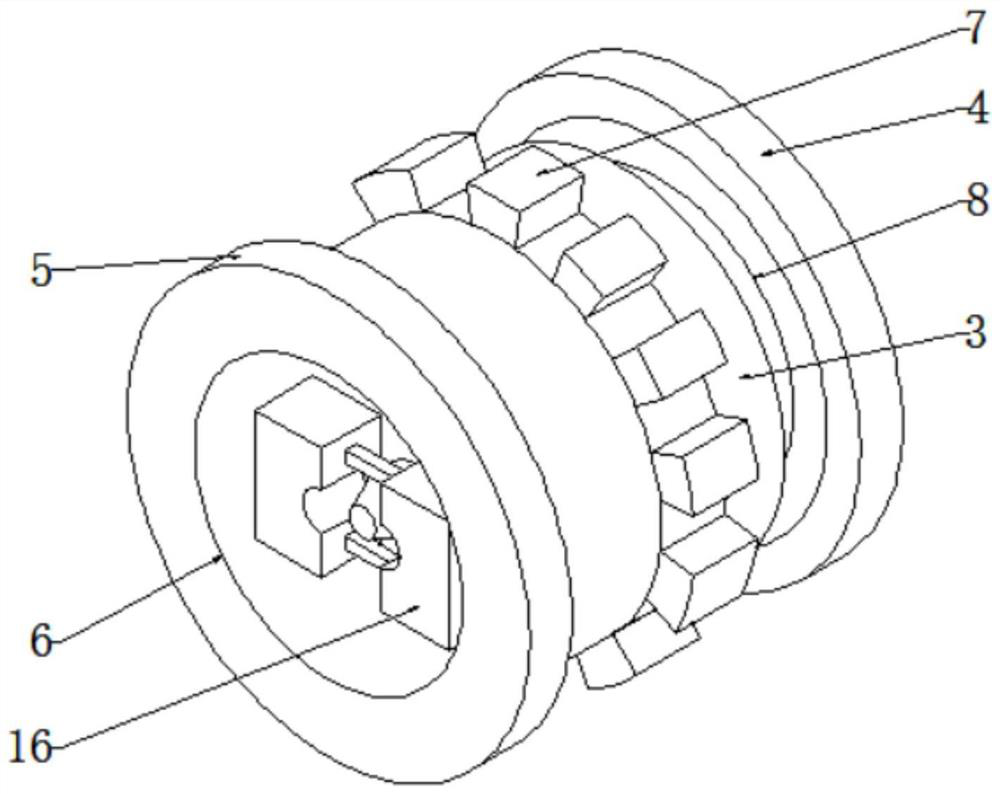

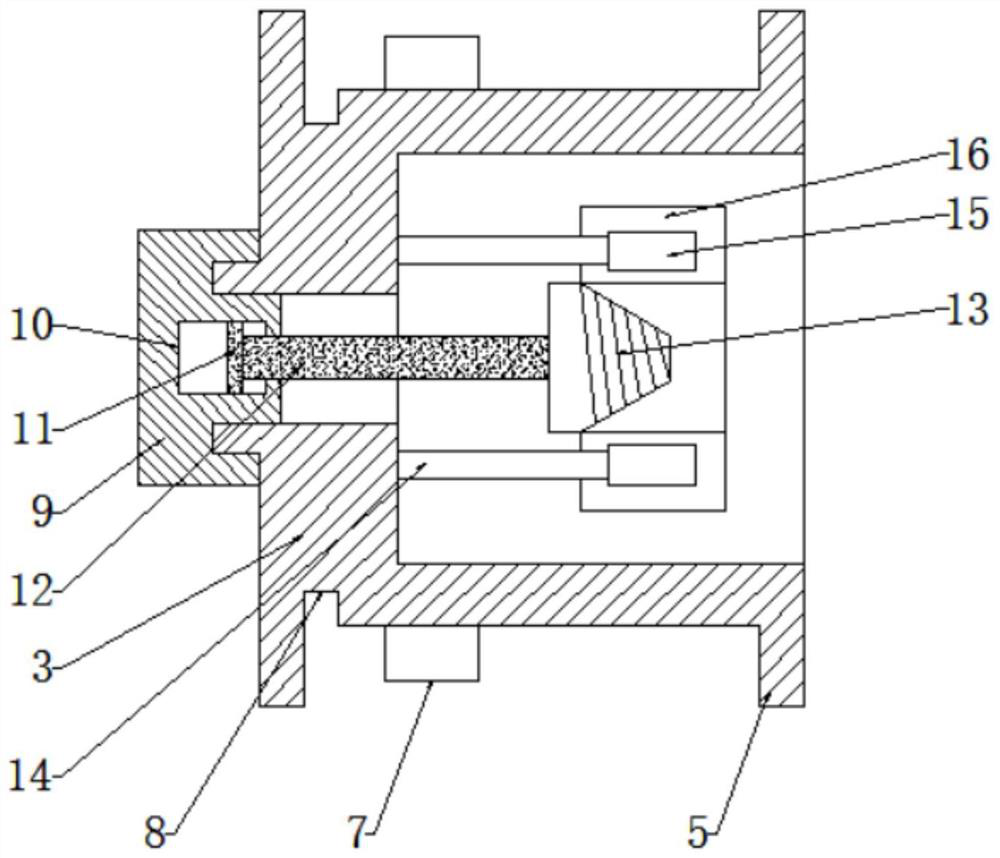

[0027] Example: such as Figure 1-6 As shown, a flame-retardant, fire-proof, and high-temperature-resistant polyethylene film laying device of the present invention includes a first support frame 1, and also includes:

[0028] The support plates 2 for supporting the polyethylene film placed at both ends of the first support frame 1, the middle parts of the two support plates 2 are all movable with a positioning frame 3, and the two ends of the positioning frame 3 are respectively provided with a first limiting plate 4 And the second limiting plate 5, the outer side of the second limiting plate 5 is provided with a cylindrical groove 6 for socketing the polyethylene film cylinder, and the middle part of the outer wall of the positioning frame 3 is evenly provided with some first holes for preventing the inertial rotation of the positioning frame 3 A stopper 7, the internal activities of the cylindrical groove 6 are provided with a top block 16 for fixing the polyethylene film c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com