Preparation method for raisin distillate for cigarettes

A technology for raisins and distillates, which is applied in the field of preparation of raisin distillates for tobacco, can solve the problems that the application requirements of cigarettes cannot be well met, the aroma of the extracts is not rich enough, the aromas of the extracts are insufficient, etc. Ideal effect, rich aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

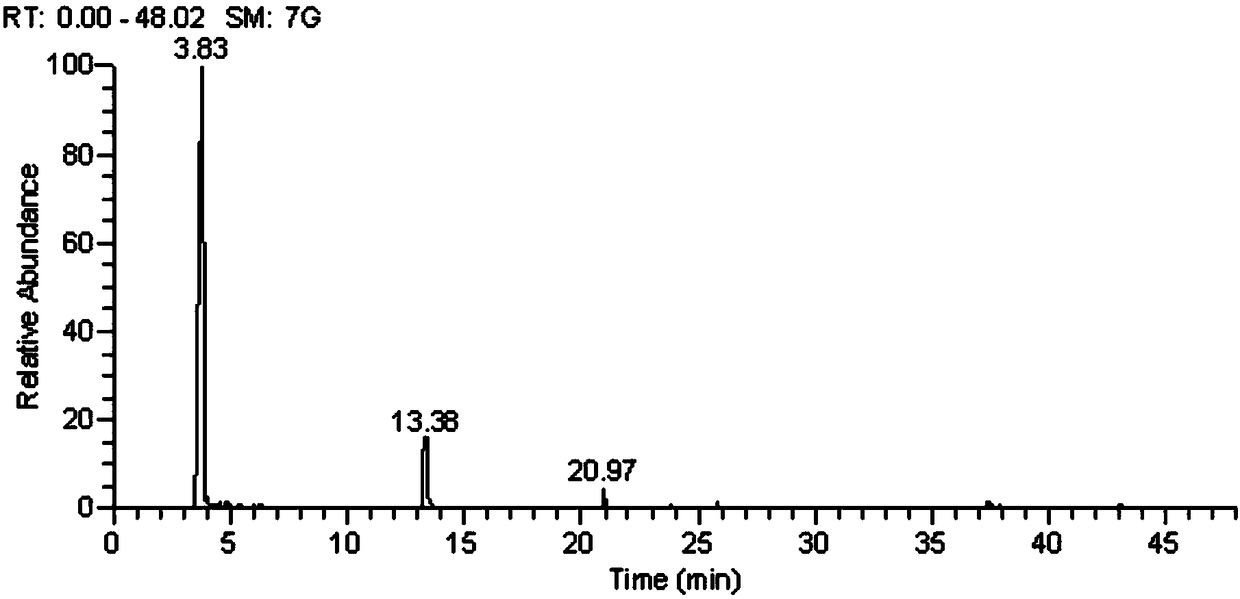

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of raisin distillate for tobacco is characterized in that concrete steps comprise:

[0025] (1) Take a certain quality of raisins, crush the raisins raw materials to about 1 / 3 of the original volume, add tap water 6 times the weight of the processed raisins raw materials, and conduct dynamic countercurrent extraction at 60°C for 2.5 hours. After the extraction, Rough filtration obtains filtrate A;

[0026] (2) Add 2.5 times the amount of 85% ethanol aqueous solution to the raisin slag extracted in step (1), conduct ultrasonic extraction for 3 hours at a temperature of 45° C. and an ultrasonic frequency of 60 kHz, and after the extraction is completed, coarsely filter to obtain the filtrate B;

[0027] (3) Slowly pour the filtrate A extracted in the step (1) into the filtrate B extracted in the step (2), stir while adding, make it fully mix, then put the combined extract at -0.095MPa , under the condition of 52°C, concentrate ...

Embodiment 2

[0032] Embodiment 2, a kind of preparation method of raisin distillate for tobacco, is characterized in that concrete steps comprise:

[0033] (1) Take a certain quality of raisins, crush the raisins raw materials to about 1 / 3 of the original volume, add tap water 8 times the weight of the processed raisins raw materials, and extract dynamically under the condition of 65°C for 2 hours. After the extraction, the crude Filter to obtain filtrate A;

[0034] (2) Add 3 times the amount of 85% ethanol aqueous solution to the raisin residue extracted in step (2), and conduct ultrasonic extraction for 1.5 hours at a temperature of 60° C. and an ultrasonic frequency of 50 kHz. After the extraction is completed, rough filter to obtain Filtrate B;

[0035] (3) Slowly pour the filtrate A extracted in the step (1) into the filtrate B extracted in the step (2), stir while adding, make it fully mixed, then the combined extract is at -0.090MPa, 55 Under the condition of ℃, concentrate under...

Embodiment 3

[0040] Embodiment 3, a kind of preparation method of raisin distillate for tobacco is characterized in that concrete steps comprise:

[0041] (1) Take a certain quality of raisins, crush the raisins raw materials to about 1 / 3 of the original volume, add tap water 5 times the weight of the processed raisins raw materials, and extract dynamically under the condition of 65 °C for 3 hours. After the extraction, the crude Filter to obtain filtrate A;

[0042] (2) Add 2 times the amount of 85% ethanol aqueous solution to the raisin residue extracted in step (1), and conduct ultrasonic extraction for 2 hours at a temperature of 45°C and an ultrasonic frequency of kHz. B;

[0043] (3) Slowly pour the filtrate A extracted in the step (1) into the filtrate B extracted in the step (2), stir while adding, make it fully mix, and combine the extract at -0.095MPa, Concentrate under reduced pressure to a relative density of 1.0157 at 50°C to obtain a raisin concentrate;

[0044] (4) Add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com