Full-automatic production equipment of bubble cap capsule stitching for bag making and working method thereof

A kind of production equipment and fully automatic technology, which is applied in the direction of bag making operation, container manufacturing machinery, flexible container manufacturing, etc., can solve the problems of low quality reliability, low production efficiency, and increased workload, so as to reduce labor load and improve Productivity, the effect of changing the way of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

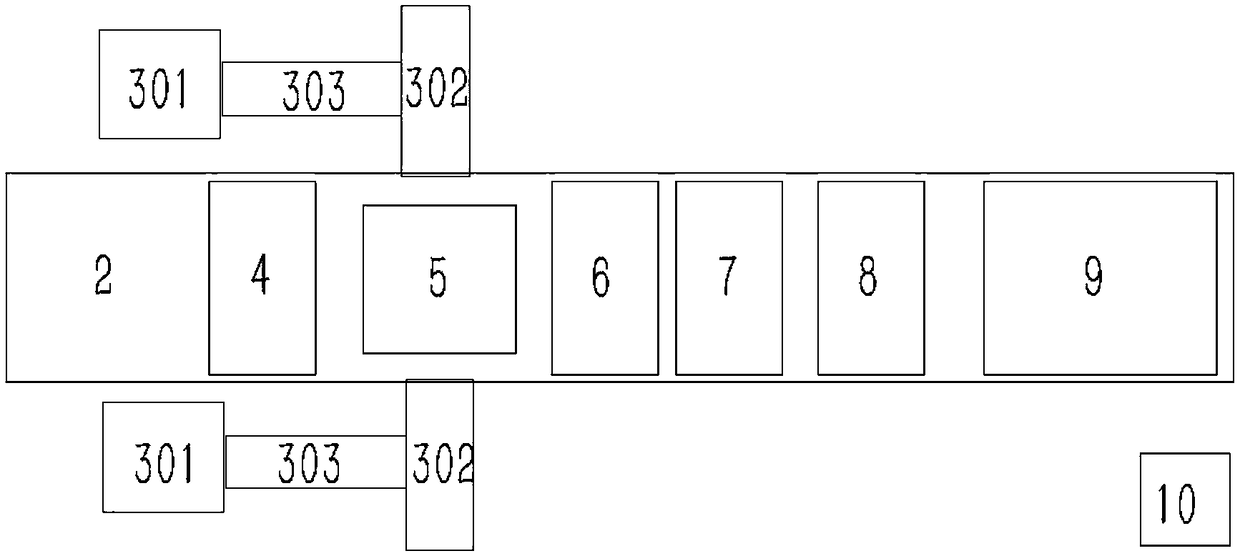

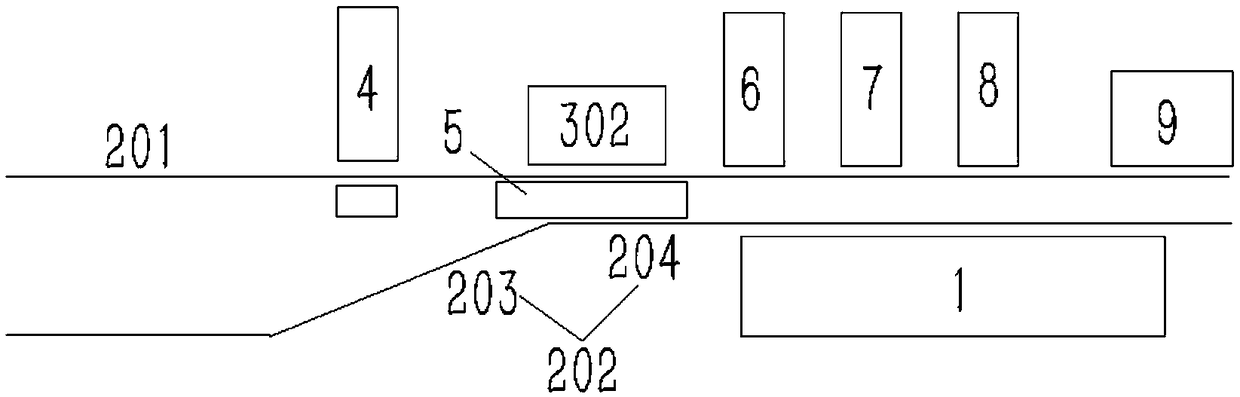

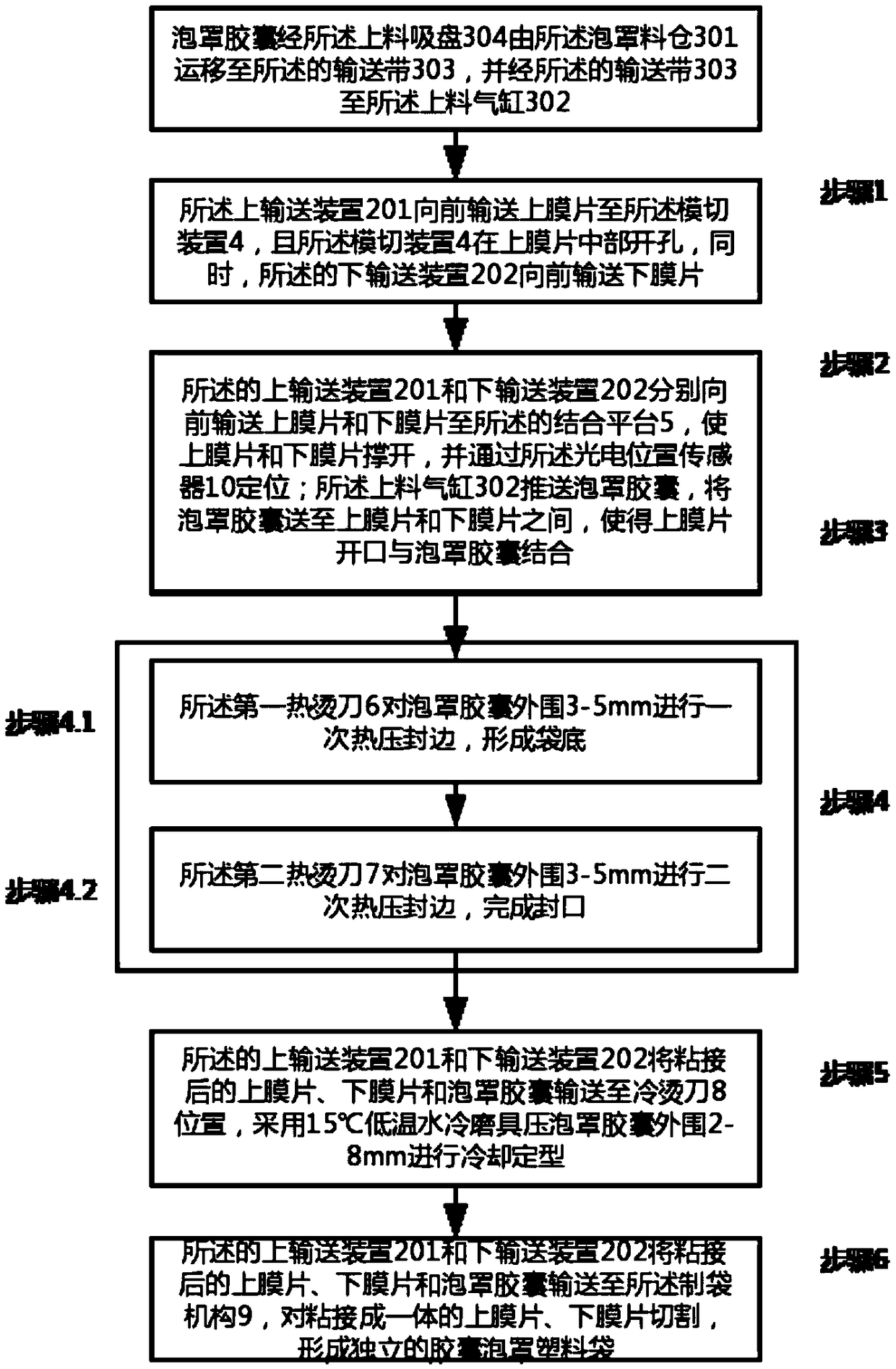

[0027] Please see attached figure 1 to attach image 3 As shown, a fully automatic production equipment for blister capsule sewing and bag making, including a frame 1 and a conveying device 2 arranged on the frame, a blister feeding mechanism 3, a die-cutting device 4, a combination platform 5, a second A blanching knife 6, a second blanching knife 7, a cold blanching knife 8 and a bag-making mechanism 9; the blister feeding mechanism 3 includes a blister feed bin 301, a feeding cylinder 302, and connects the blister material The conveyor belt 303 of the bin 301 and the feeding cylinder 302; the conveying device 2 includes an upper conveying device 201 and a lower conveying device 202, and the lower conveying device 202 is arranged below the upper conveying device 201; The moving direction of the upper conveying device 201 is the same as the moving dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com