Artificial streaky beef steak and preparation method thereof

A snowflake cow, artificial technology, applied in the direction of food ingredients as taste improvers, food ingredients as odor improvers, food science, etc., to increase the number of people who eat and taste better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention discloses a preparation method of artificial snowflake steak, in which milk seasoning is heated to a liquid state, and high pressure is quickly injected into beef in a low temperature state.

[0042] Specifically, the following steps are carried out in sequence:

[0043] ① Material preparation:

[0044] (1) Prepare beef with a center temperature of 5-8°C;

[0045] (2) Prepare the milk seasoning: stir the milk and butter of the corresponding weight evenly, add the compound phosphate of the corresponding weight, and the auxiliary material mixed with citric acid, edible salt and black pepper juice, and stir homogeneously for 30-60 minutes, And heated to 40 ~ 70 ℃,

[0046]②Injection treatment: Inject the milk seasoning of the corresponding weight ratio into the beef, the injection pressure is 0.9-1.5kg / cm, the flow rate is 2-5 liters / min, and the time is 1-3 seconds.

[0047] ③Preservation treatment: physical oxygen barrier treatment, here you can use plas...

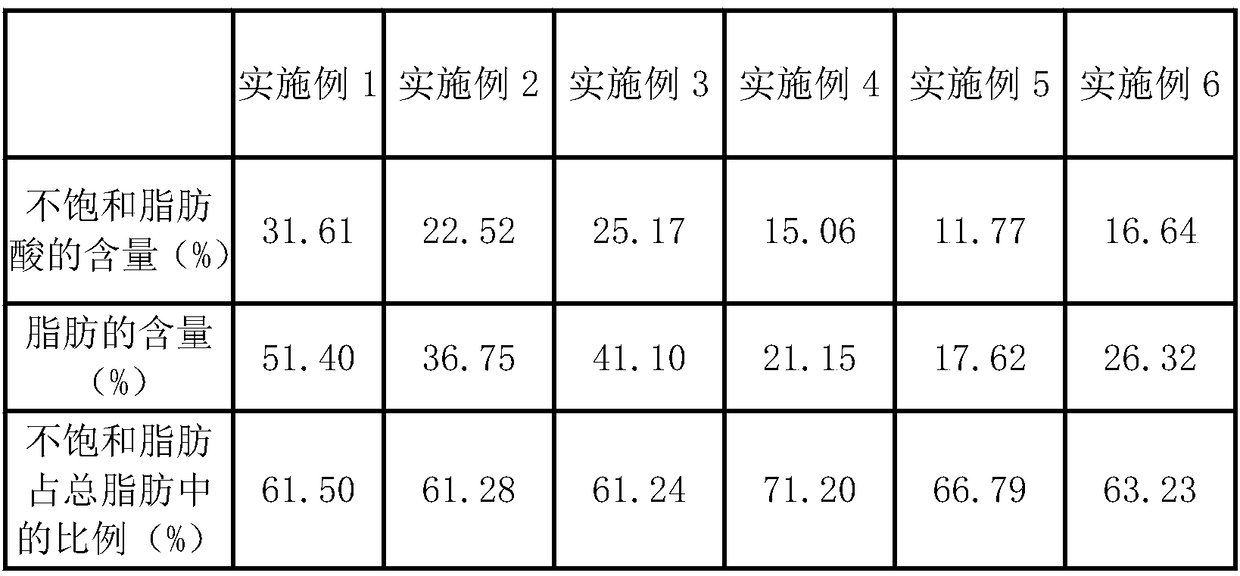

Embodiment 1

[0055] A faux snowflake steak, including 100g milk seasoning and 900g beef. Wherein, the milk seasoning comprises the following components, 40g of milk, 50g of butter and 10g of auxiliary materials, and the auxiliary materials are compound phosphate, citric acid and other necessary seasonings.

[0056] The specific steps for preparing the snowflake steak are:

[0057] ① Material preparation:

[0058] (1) Prepare beef with a center temperature of 5°C;

[0059] (2) Prepare milk seasoning: the milk and butter of above-mentioned weight are stirred evenly, add 0.4% compound phosphate and 0.2% citric acid, 2.2% edible salt, surplus is that black pepper juice is mixed into the auxiliary material of described weight, Stir homogeneously for 30 minutes, and heat to 40° C. to obtain the milk seasoning.

[0060] The added amount of compound phosphate is 0.4%, the added amount of citric acid is 0.2%

[0061] ②Injection treatment: inject the corresponding weight of milk seasoning into t...

Embodiment 2

[0065] A faux snowflake steak including 400g milk seasoning and 90g beef.

[0066] Wherein, the milk seasoning comprises the following components by weight: 200g of milk, 100g of butter, 40g of shea butter extract and 60g of auxiliary materials, the auxiliary materials being compound phosphate, citric acid and other necessary seasonings.

[0067] The specific steps for preparing the snowflake steak are:

[0068] ① Material preparation:

[0069] (1) Prepare beef with a central temperature of 8°C;

[0070] (2) Prepare the milk flavoring:

[0071] The preparation method of shea butter extract:

[0072] Step 1, mash the avocado into a puree;

[0073] Step 2, add 4 times the weight of distilled water to the avocado puree to dissolve, then add cellulase, enzymatically decompose the cellulose, inactivate the enzyme, centrifuge and filter to obtain the precipitate, and the supernatant is left to stand and layered to obtain the oil layer;

[0074] Step 3: add cellulase and neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com