High pressure water jet cleaning experimental device

A technology of high-pressure water jets and experimental devices, applied in cleaning methods and utensils, cleaning methods using liquids, instruments, etc., to achieve simple results, easy operation, and intuitive experimental phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

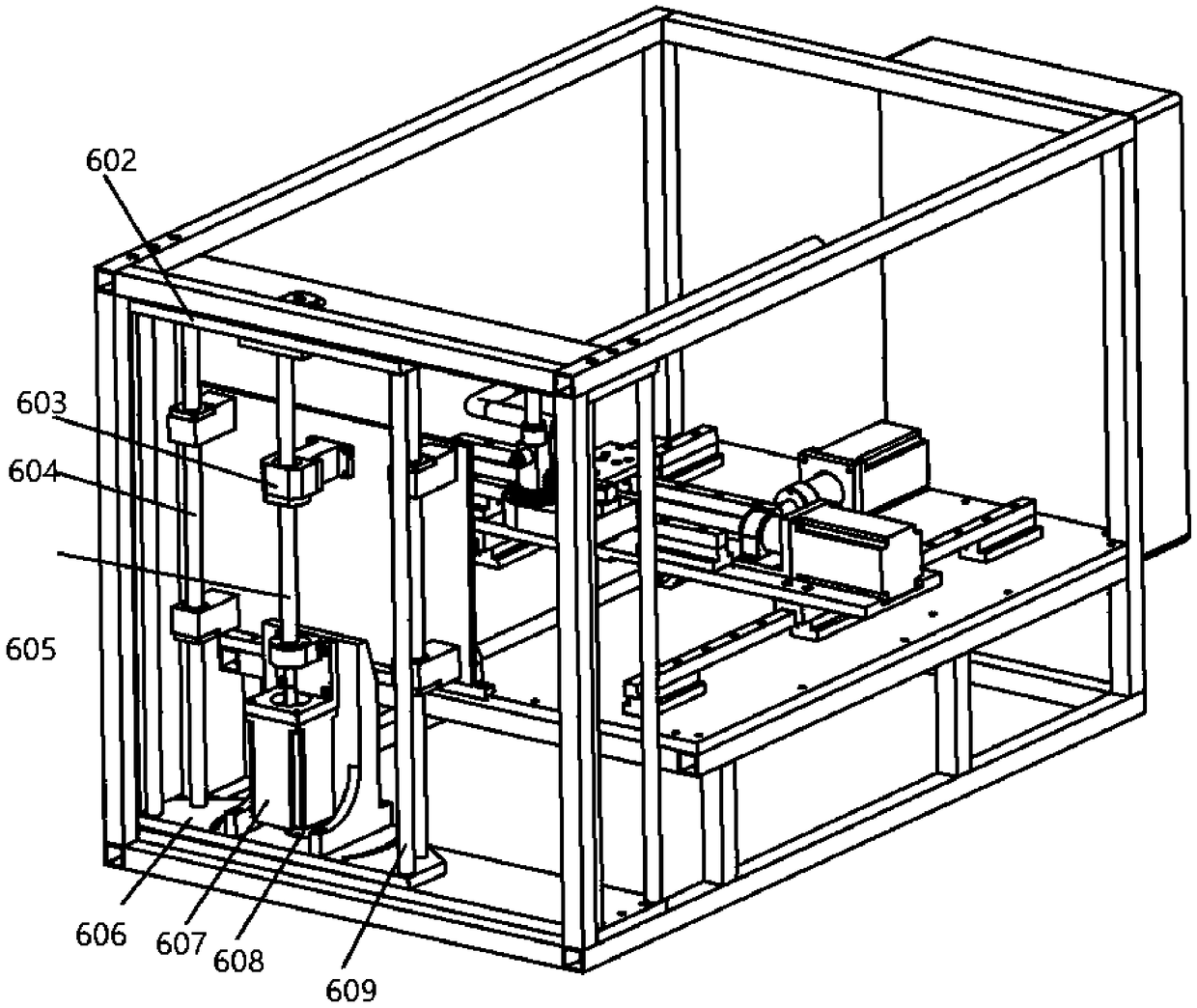

[0050] Such as Figure 6 Before the experiment, it is necessary to prepare the dirt into a sample, fill the dirt into the sample preparation mold, heat or use other methods according to the nature of the dirt to melt and evenly adhere to the target bottom plate 610 . Then remove the side plate 1 611 and side plate 2 612 and the inner-lined aluminum foil tape by disassembling the bolts, and finally form the target bottom plate 610 with dirt attached. 610 is fixed on the dirt plate 60 with bolts.

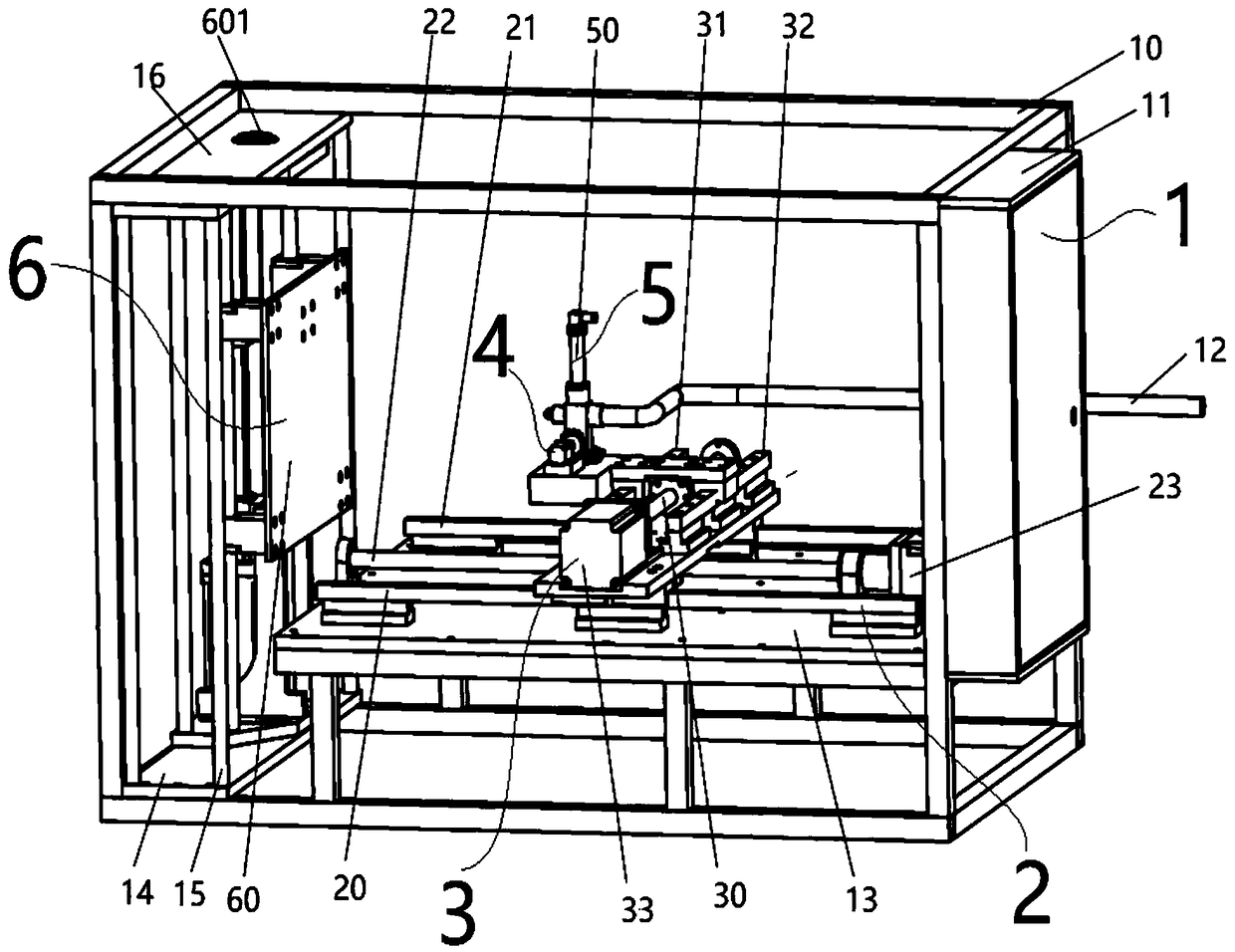

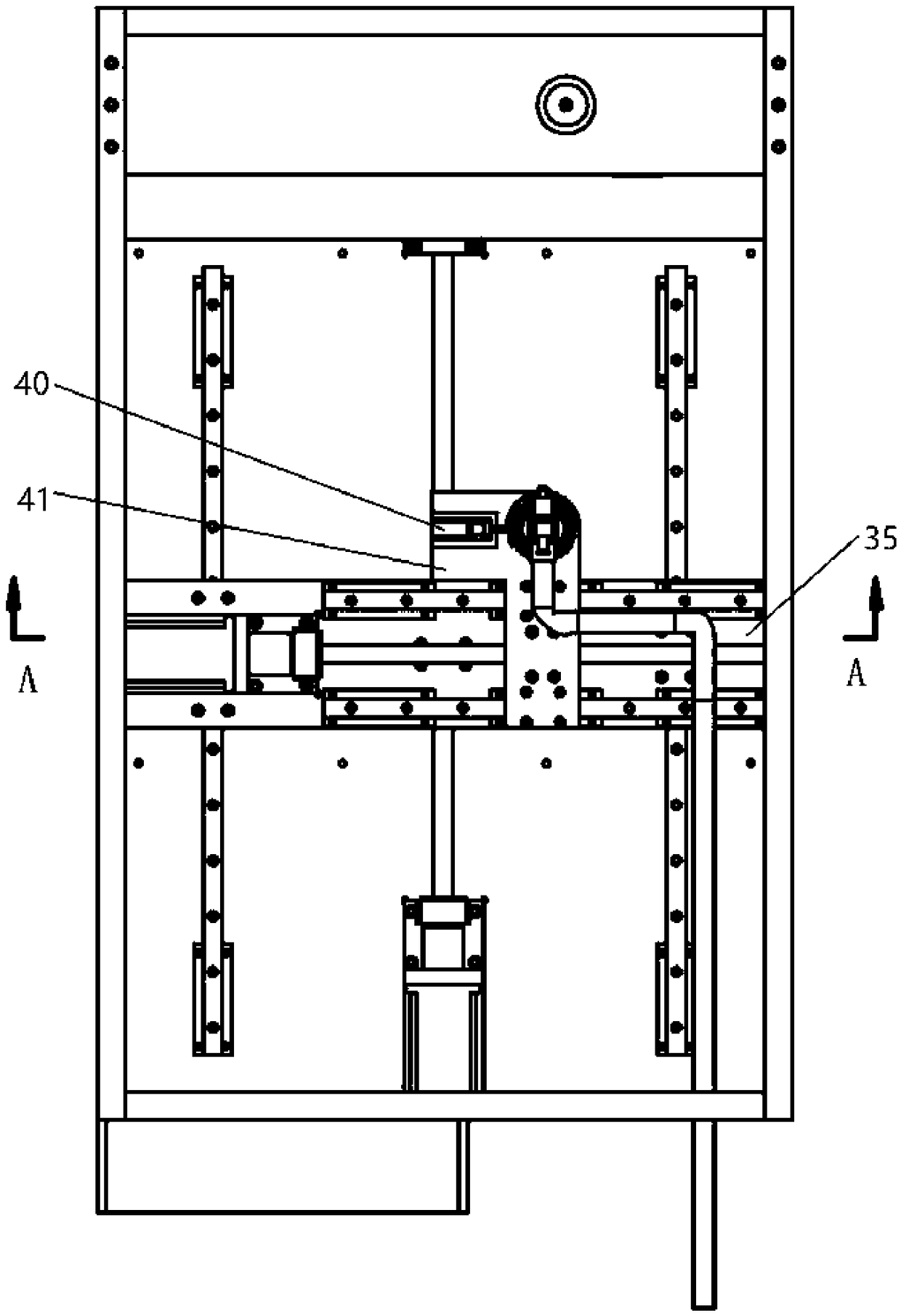

[0051]Prepare several different dirts into samples respectively, fix one of the samples on the dirt plate 60, adjust the installation angle and starting position of the dirt plate 60, adjust the installation angle, the starting position and the starting position of the nozzle 44. Target distance, turn on the power, open the high-pressure water valve, and read the value fed back to the control box 11 by the pressure sensor 50 as the high-pressure water injection pressure value. Use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com