Bearing storage observing device

A technology for observing devices and bearings, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of time-consuming and labor-intensive inspection of bearings in stock, save time and effort in inspection work, avoid damage, and solve the problem of messy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

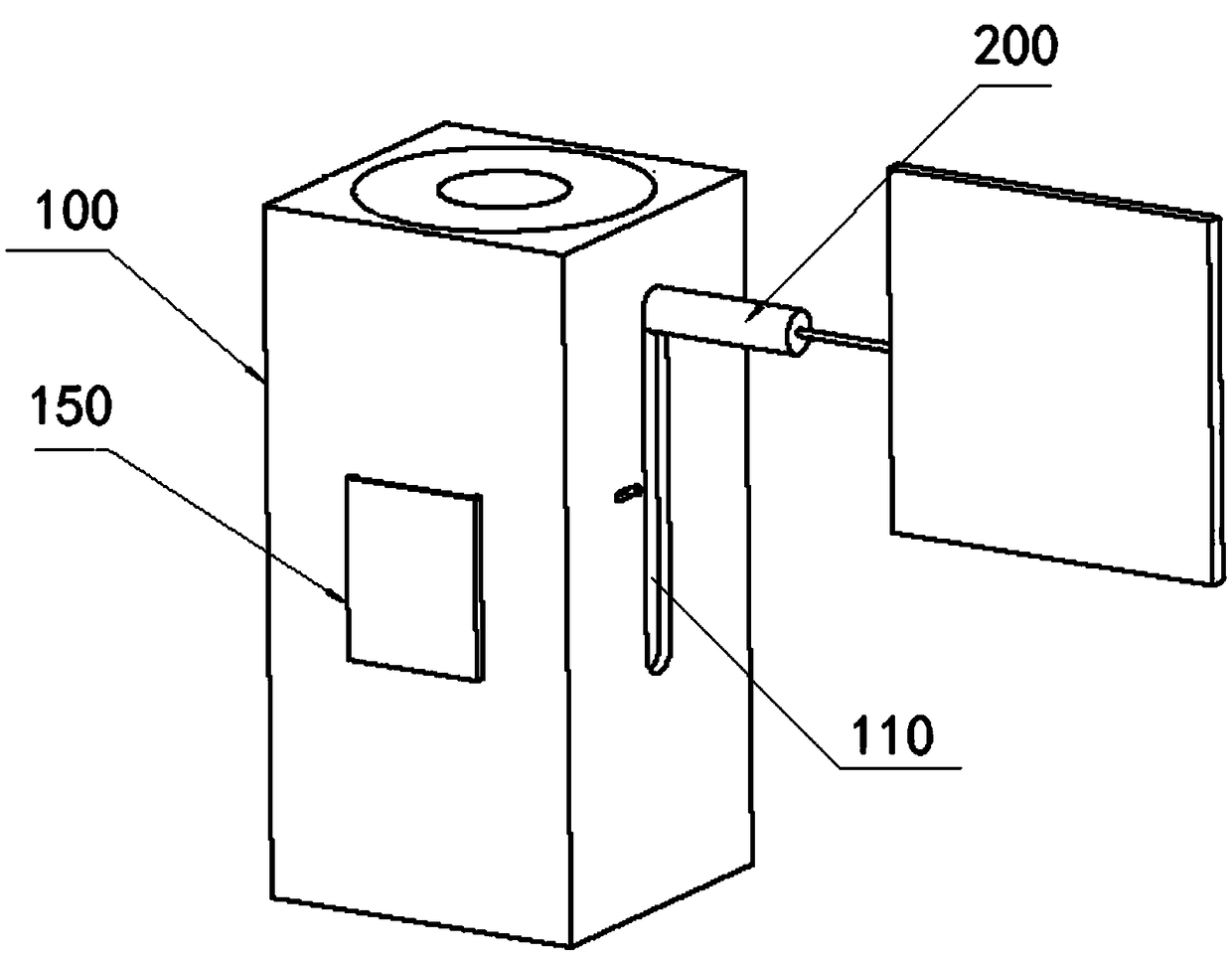

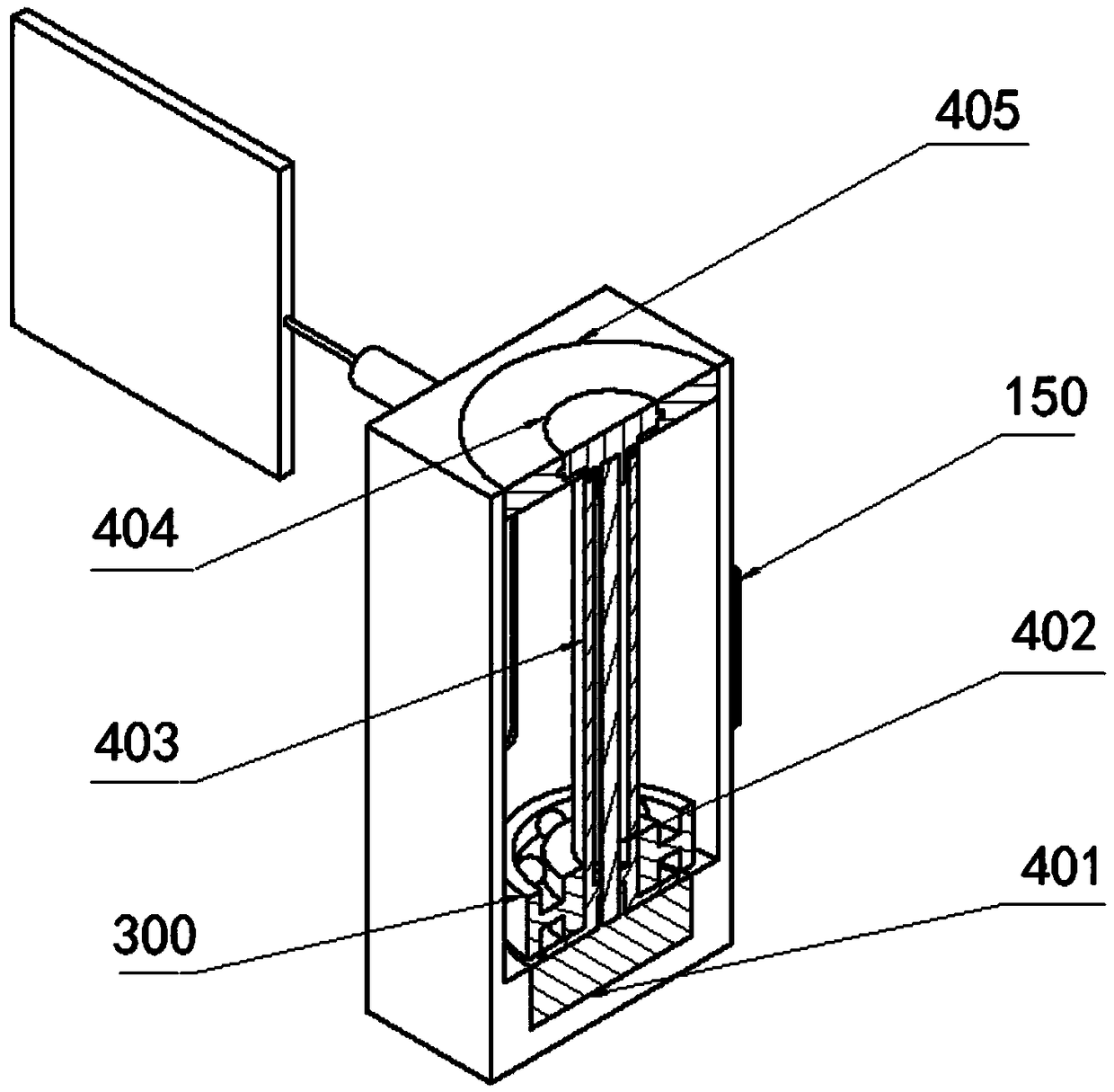

[0047]The embodiments of the present application provide a bearing storage and observation device, which solves the problem of time-consuming and laborious inspection of stock bearings in the prior art, and realizes the convenience and speed of bearing inspection.

[0048] The technical solution in the embodiment of this application is to solve the problem of time-consuming and labor-intensive regular inspection of the above-mentioned stock bearings. The general idea is as follows:

[0049] By setting up a storage box that can stack the bearings into a stack, the orderly stacking of the bearings is realized. The images of the bearings are obtained by setting the observation unit that can observe the bearings in the storage box, and the bearings can be inspected by observing the images obtained by the observation unit, without taking the bearings out of the storage box for inspection one by one, so that the inspection of the bearings in stock Work easily and quickly.

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com