Test platform for front fork tube of front shock absorber of motorcycle

The technology of front shock absorber and test platform is applied in the field of test platform of front fork tube of motorcycle front shock absorber, which can solve problems such as inaccurate data, and achieve the effects of good simulation test, simple structure and reduction of hardware cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

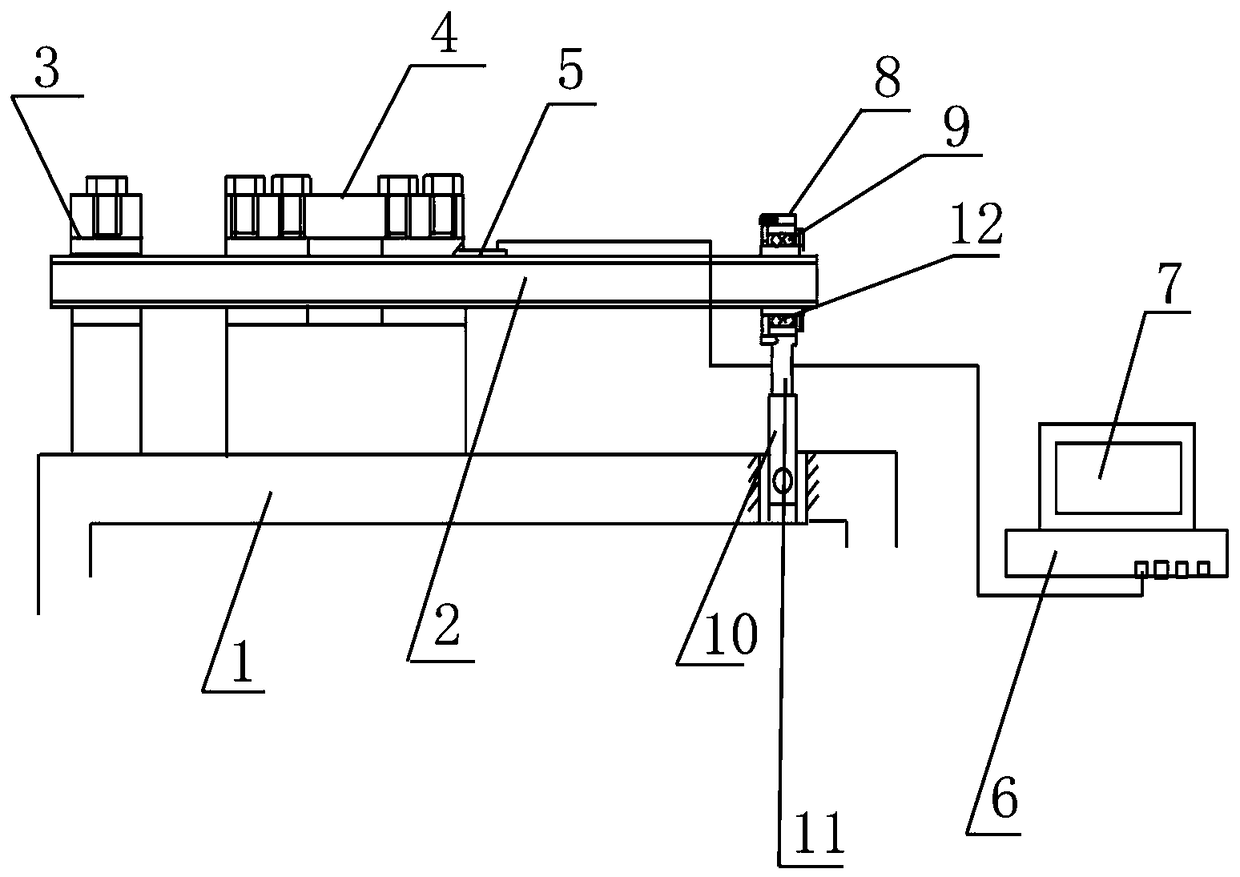

[0009] exist figure 1 Among them, the present invention provides a test platform for the front fork tube of a motorcycle front shock absorber, which includes a base 1, a sinusoidal slider mechanism is arranged on one side of the base 1, and a bracket 2 is installed on the upper part of the sinusoidal slider mechanism , one end of the bracket 2 is connected with the sinusoidal slider mechanism, the other end of the sinusoidal slider mechanism is installed with a jacket I3, and the middle part of the base 1 is equipped with a jacket II4, which is set on the bracket 2 as the clamping position 4 of the real vehicle. A laser displacement sensor 5 is also installed on the clamping position 4, the input end of the laser displacement sensor 5 is connected with the sinusoidal sliding mechanism, the output end of the laser displacement sensor 5 is connected with a PLC controller 6, and the input end of the PLC controller 6 is connected with the laser displacement The output end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com