Embedded connector

An embedded, male joint technology, applied in the field of mechanical parts, can solve the problems of low efficiency, waste of manpower, and high construction costs, and achieve the effect of enhancing multiple functions and widening industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

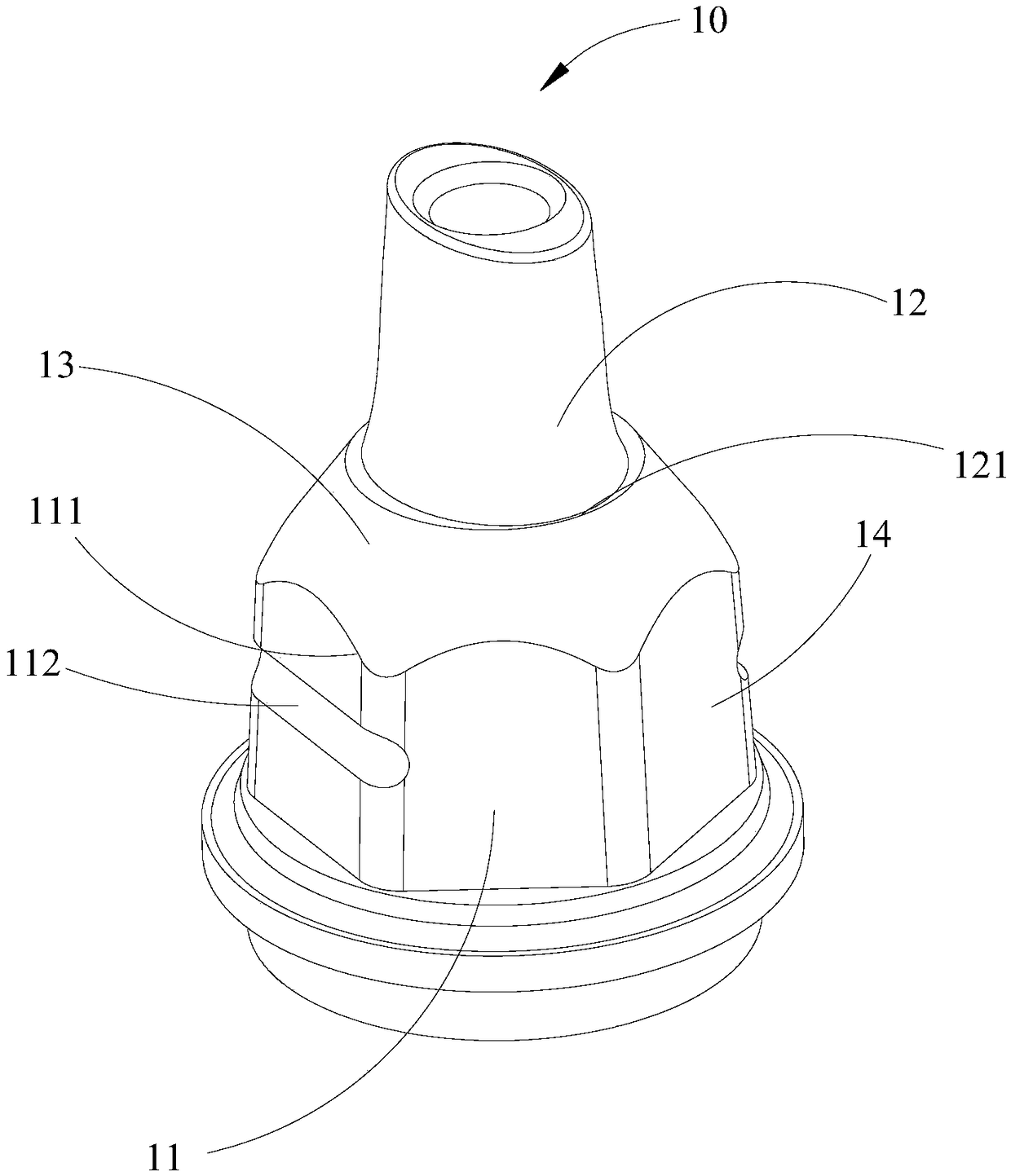

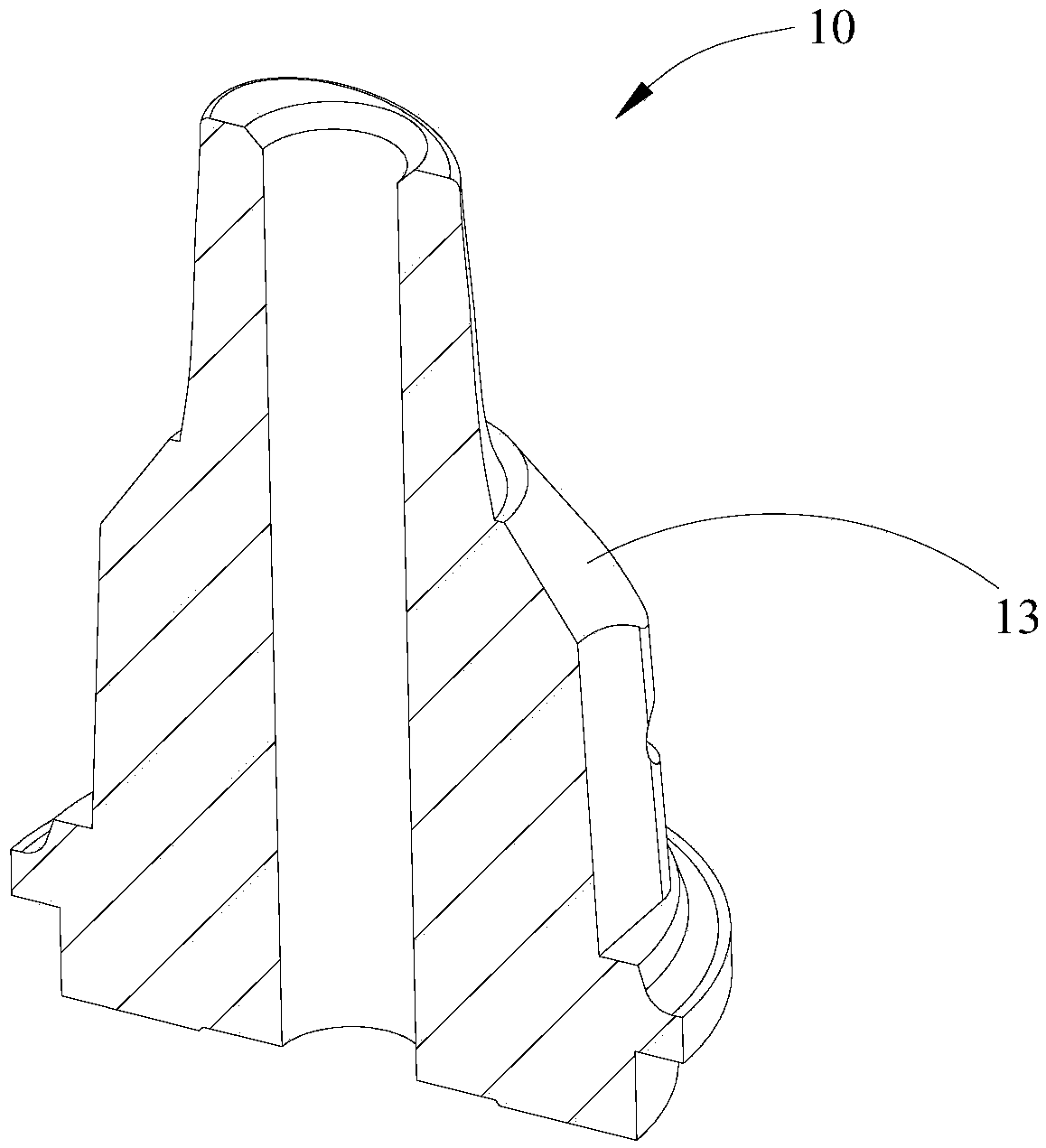

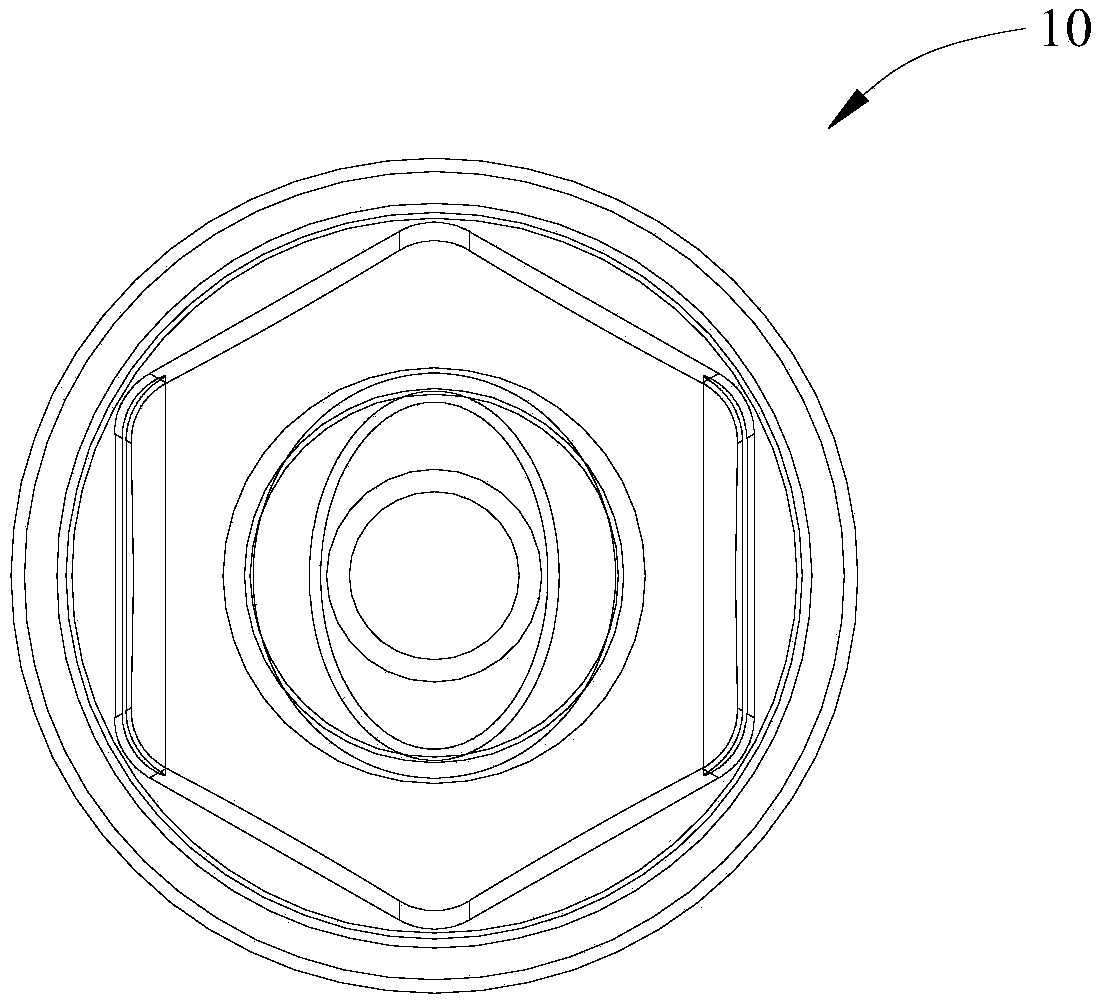

[0046] see Figure 1-8 .

[0047]An embedded joint 100 of the present invention includes a male joint 10 and a female joint 20. The male joint 10 includes a conical truncated joint body 11 and an oval truncated truncated guide head 12. The upper section 111 of the joint body is Connecting the bottom surface 121 of the guide head, the female joint 20 is provided with an accommodating and guiding through hole 21 for accommodating the male joint 10 , the shape of the accommodating and guiding through hole 21 is consistent with the shape of the male joint 10 Correspondingly, the joint body 11 is provided with a locking groove 112, and the side of the female joint 20 is provided with a locking pin through hole 22 corresponding to the locking groove 112, and the embedded joint 100 also includes an insertion The locking pin 22 is inserted into the locking groove 112 through the hole 22 so that the male connector 10 and the female connector 20 are fixedly connected to the locking pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com