Double-suction double-shaft multi-stage axially split pump system

A pump system and first-level technology, applied to pumps, pump devices, pump components, etc., can solve problems such as high energy consumption and serious water pump cavitation, achieve the goals of reducing output energy consumption, increasing yield, and eliminating hidden dangers of cavitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

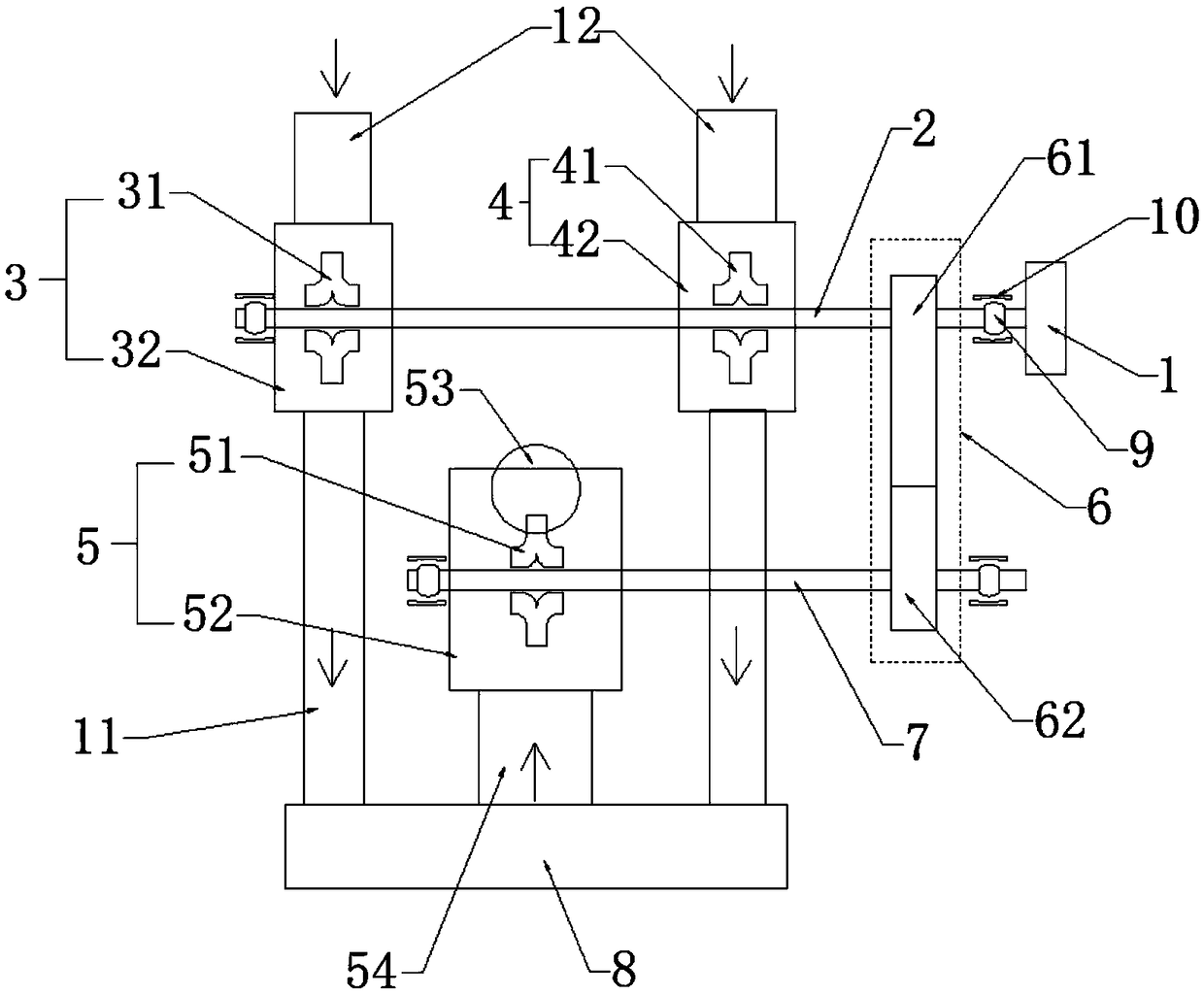

[0039] like figure 1 shown, with figure 1 The direction of the arrow in the figure is the water flow direction when the split pump is working. A double-suction, multi-axis and multi-stage split pump system of the present invention includes the main power source 1, the main transmission shaft 2, the first head water pump 3, the second head pump Primary water pump 4, at least one secondary main water pump 5, transmission gear pair 6 and at least one secondary main transmission shaft 7;

[0040] The main power source 1 provides power for the first primary water pump 3 and the second primary water pump 4 through the main transmission shaft 2;

[0041] The main power source 1 provides power for the secondary main water pump 5 through the main transmission shaft 2, the transmission gear pair 6 and the secondary main transmission shaft 7;

[0042] The first primary water pump 3 and the second primary water pump 4 are respectively connected to the secondary main water pump 5 through...

Embodiment 2

[0054] likefigure 1 As shown, a double-suction, multi-shaft and multi-stage split pump system of the present invention includes a main power source 1, a main transmission shaft 2, a first first-stage water pump 3, a second first-stage water pump 4, and at least one secondary main water pump 5 , transmission gear pair 6 and at least one secondary main transmission shaft 7;

[0055] The main power source 1 provides power for the first primary water pump 3 and the second primary water pump 4 through the main transmission shaft 2;

[0056] The main power source 1 provides power for the secondary main water pump 5 through the main transmission shaft 2, the transmission gear pair 6 and the secondary main transmission shaft 7;

[0057] The first primary water pump 3 and the second primary water pump 4 are respectively connected to the secondary main water pump 5 through external pipes 8 .

[0058] Further, the first first stage water pump 3 includes a first first stage impeller 31 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com