Four-post lifting machine for preventing car from slipping

A lift and skid technology, which is applied in the directions of lifting frames, lifting devices, lighting devices, etc., can solve the problems of injury to maintenance personnel, personal safety hazards, and accumulation of debris on the surface of the bottom plate, so as to achieve safe and convenient use. , reducing safety accidents, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

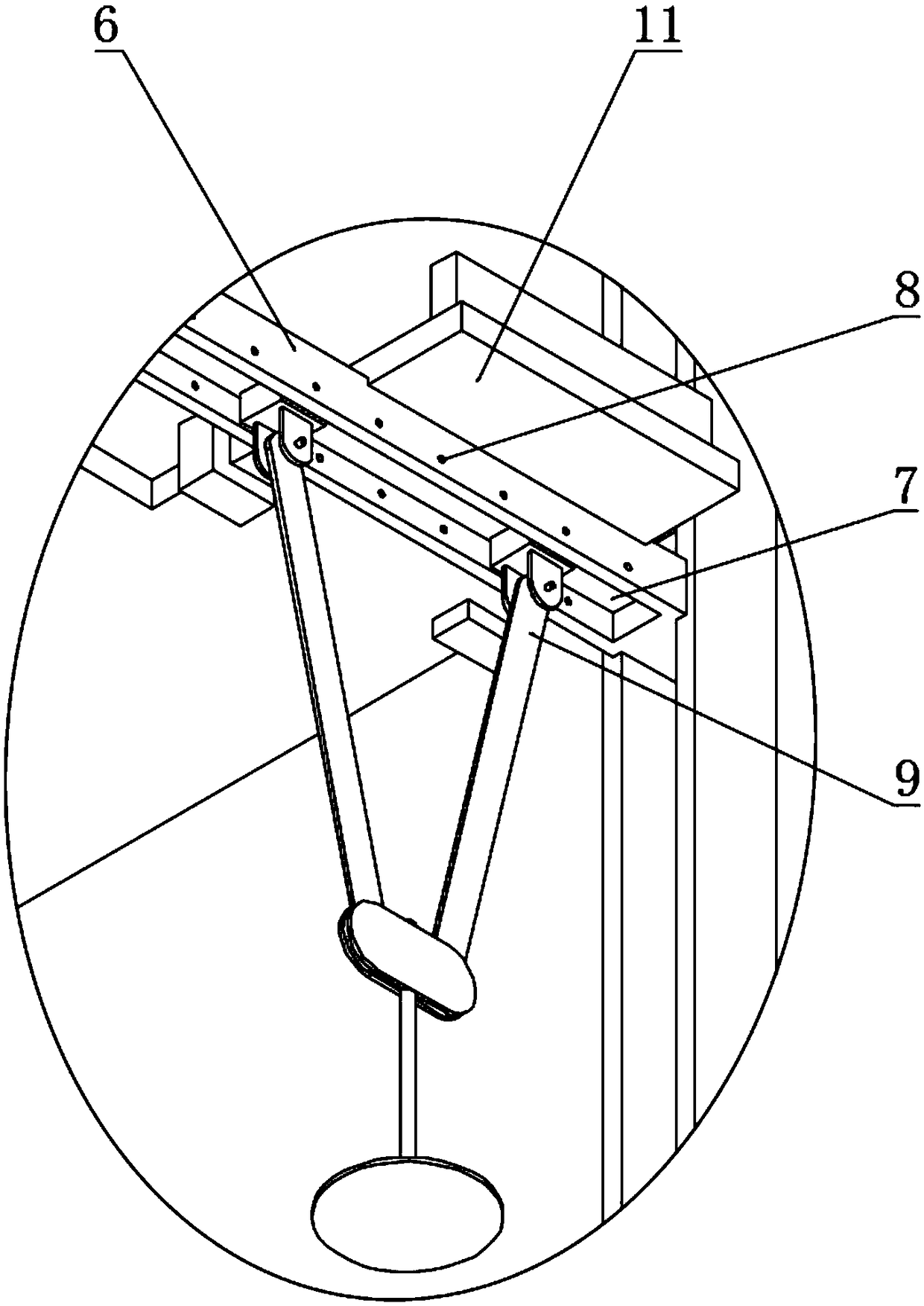

[0034] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a four-post lift for preventing automobile slipping, including a base plate 1, and uprights 2 are installed at each corner position above the base plate 1, and the uprights 2 on the same side above the base plate 1 A baffle plate 3 is installed at the position between them, and a cleaning chute 4 is provided on the side surface of the baffle plate 3, and a cleaning assembly 5 is installed on one side of the baffle plate 3 through the cleaning chute 4, and the cleaning assembly 5 includes a cleaning scraper 501 and a storage groove 502 And the slider 503, the middle part of the cleaning scraper 501 is provided with a storage groove 502, in order to ensure the stability of the cleaning scraper 501 during the movement, the number of the baffles 3 is set to two, and the ratio of the number of the cleaning chute 4 to the baffle 3 is two Compared with one, the side surface of the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com