Permanent magnetic direct drive bogie and railway vehicle thereof

A permanent magnet direct drive, bogie technology, applied in the field of rail vehicles, can solve the problems of high traction point, permanent magnet motor, not suitable for high-speed locomotives, etc., to reduce the failure rate, prolong the service life, and eliminate the problem of lubrication and sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

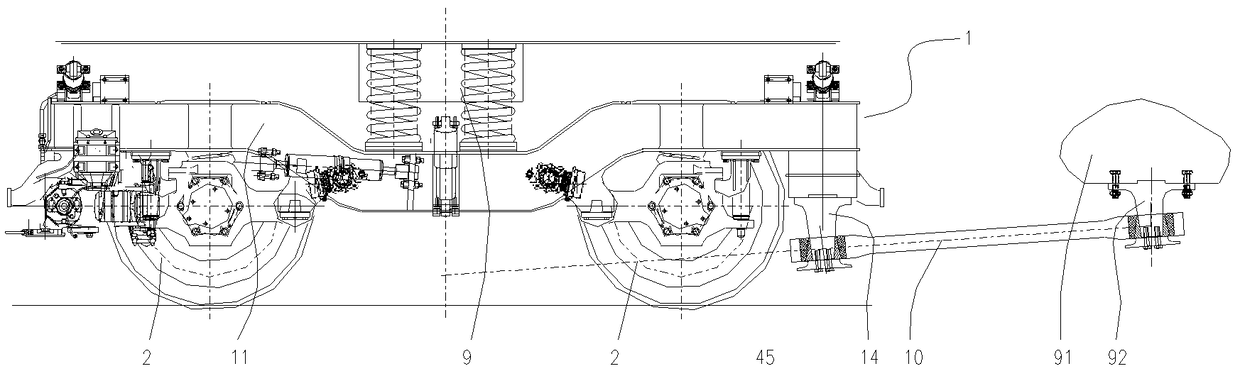

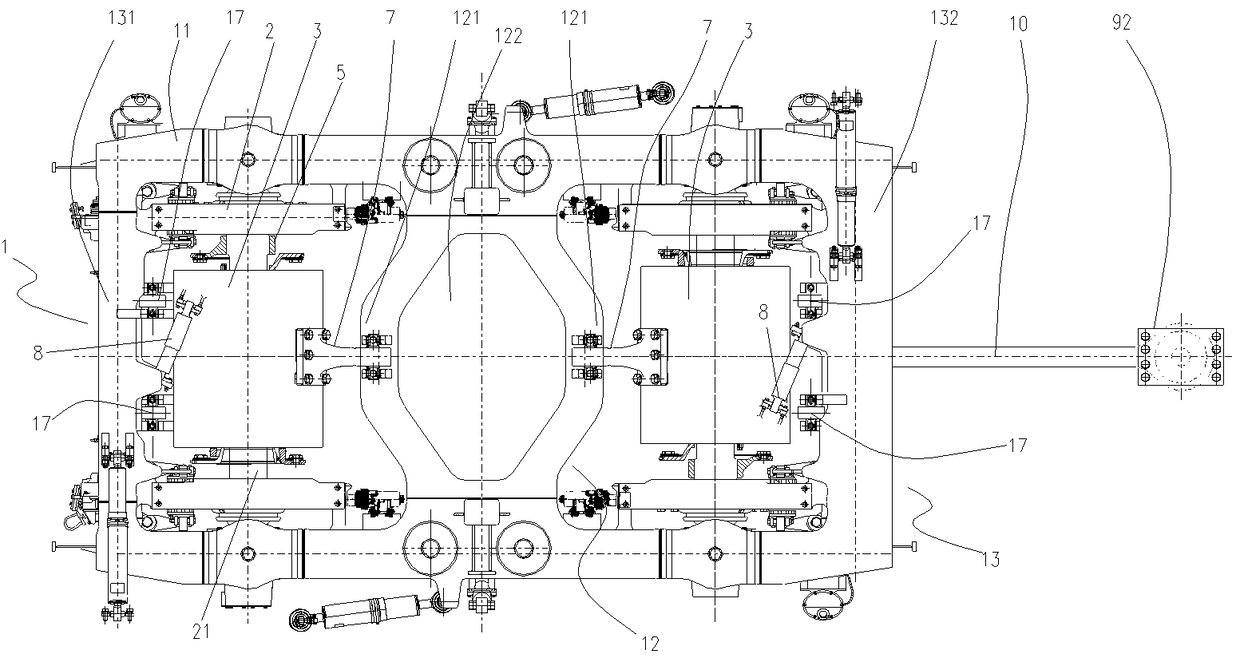

[0047] Such as Figure 1~2. As shown in 6-7, a permanent magnet direct drive bogie includes a frame 1 , a wheel set 2 arranged on the frame 1 , and a permanent magnet motor 3 . The frame 1 includes a longitudinal beam 11 , a cross beam 12 perpendicular to the longitudinal beam 11 , and end beams 13 arranged at two ends of the longitudinal beam 11 . The end beam 13 is divided into a front end beam 131 and a rear end beam 132 . A through hole 122 is defined in the middle of the beam 12 .

[0048] A hollow shaft 4 is sleeved on the axle shaft 21 of the wheel set 2 . A force transmission seat 5 is fixedly arranged on the axle shaft 21 . The permanent magnet motor 3 is sleeved on the hollow shaft 4 . One end of the hollow shaft 4 is connected to the permanent magnet motor 3 through a flexible coupling 6 , and the other end of the hollow shaft 4 is connected to the force transmission seat 5 through a flexible coupling 3 . The flexible coupling 6 is a lamination coupling. The l...

Embodiment 2

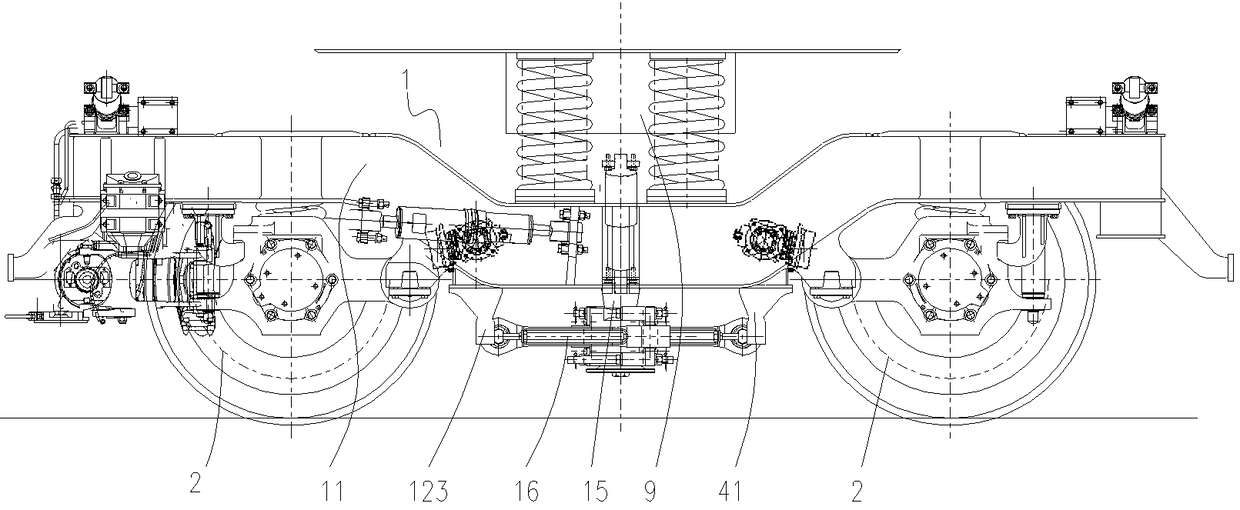

[0054] Such as Figure 3-7 As shown, a permanent magnet direct drive bogie includes a frame 1 , a wheel set 2 arranged on the frame 1 , and a permanent magnet motor 3 . The frame 1 includes a longitudinal beam 11 , a cross beam 12 perpendicular to the longitudinal beam 11 , and end beams 13 arranged at two ends of the longitudinal beam 11 . The end beam 13 is divided into a front end beam 131 and a rear end beam 132 . A through hole 122 is defined in the middle of the beam 12 .

[0055] A hollow shaft 4 is sleeved on the axle shaft 21 of the wheel set 2 . A force transmission seat 5 is fixedly arranged on the axle shaft 21 . The permanent magnet motor 3 is sleeved on the hollow shaft 4 . One end of the hollow shaft 4 is connected to the permanent magnet motor 3 through a flexible coupling 6 , and the other end of the hollow shaft 4 is connected to the force transmission seat 5 through a flexible coupling 3 .

[0056] In this embodiment, the flexible coupling 6 is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com