Central cross beam type traction device

The technology of a traction device and a beam is applied in the field of traction devices, which can solve the problems of increasing the energy consumption of longitudinal traction force transmission, affecting the comfort of passengers riding on rail vehicles, and cumbersome parts maintenance process, so as to improve the adhesion utilization rate, reliable transmission, and convenience. The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

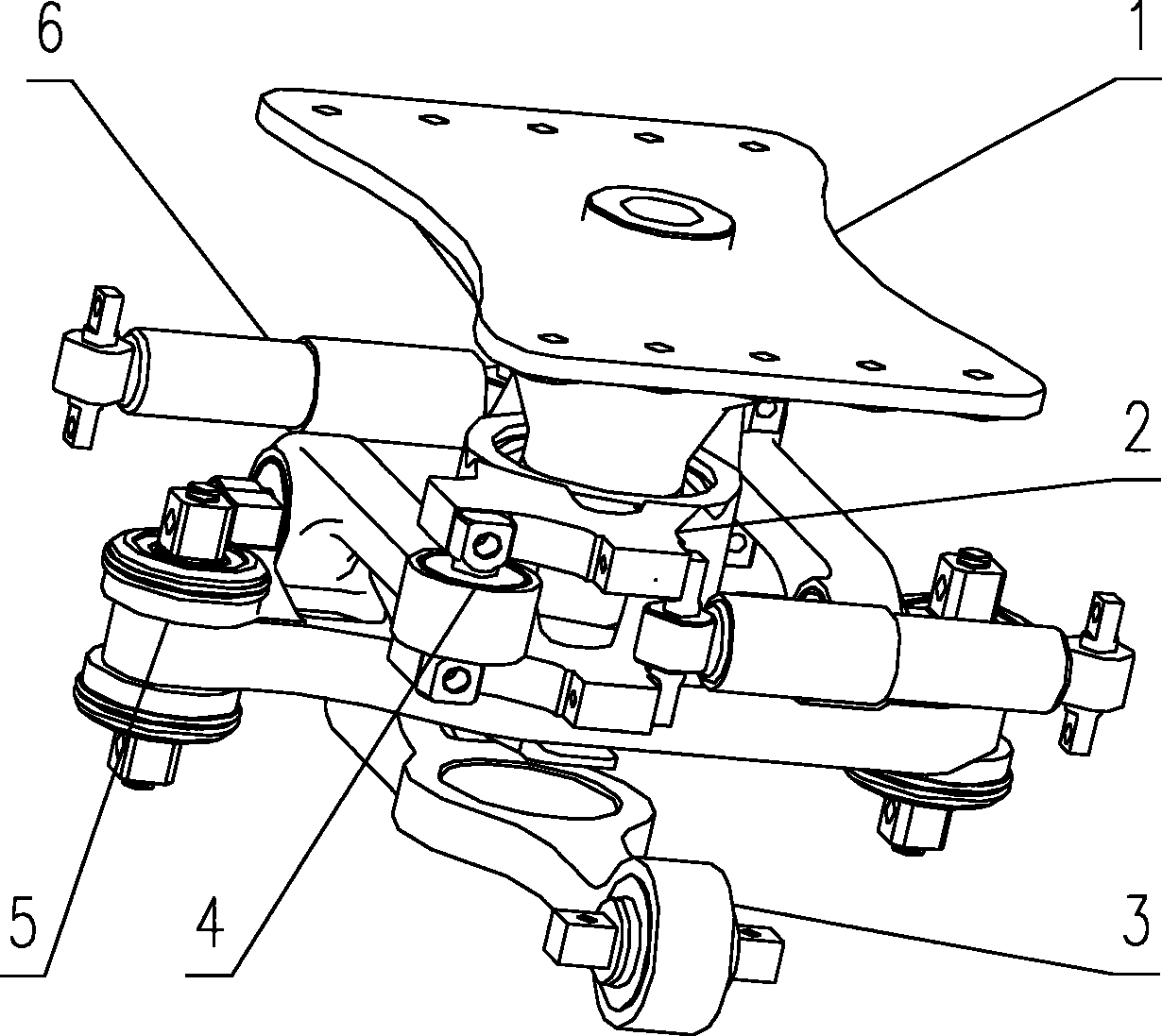

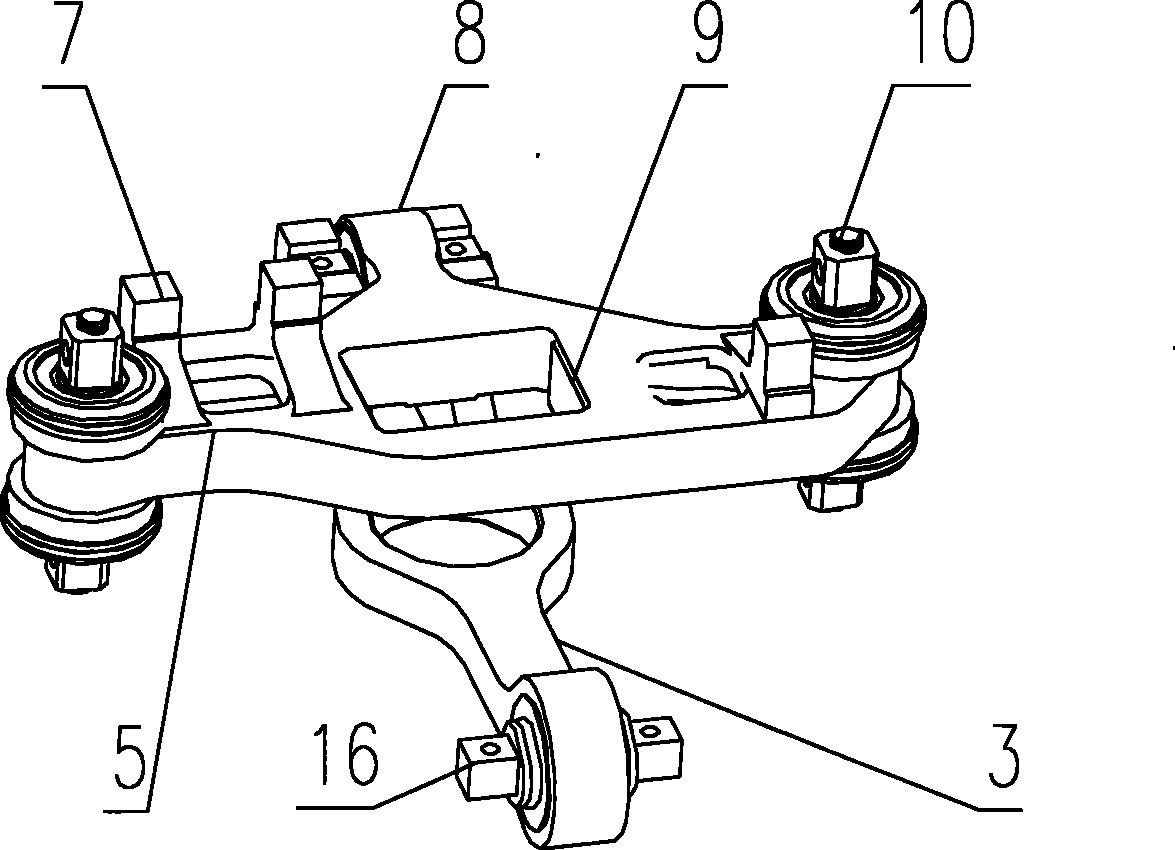

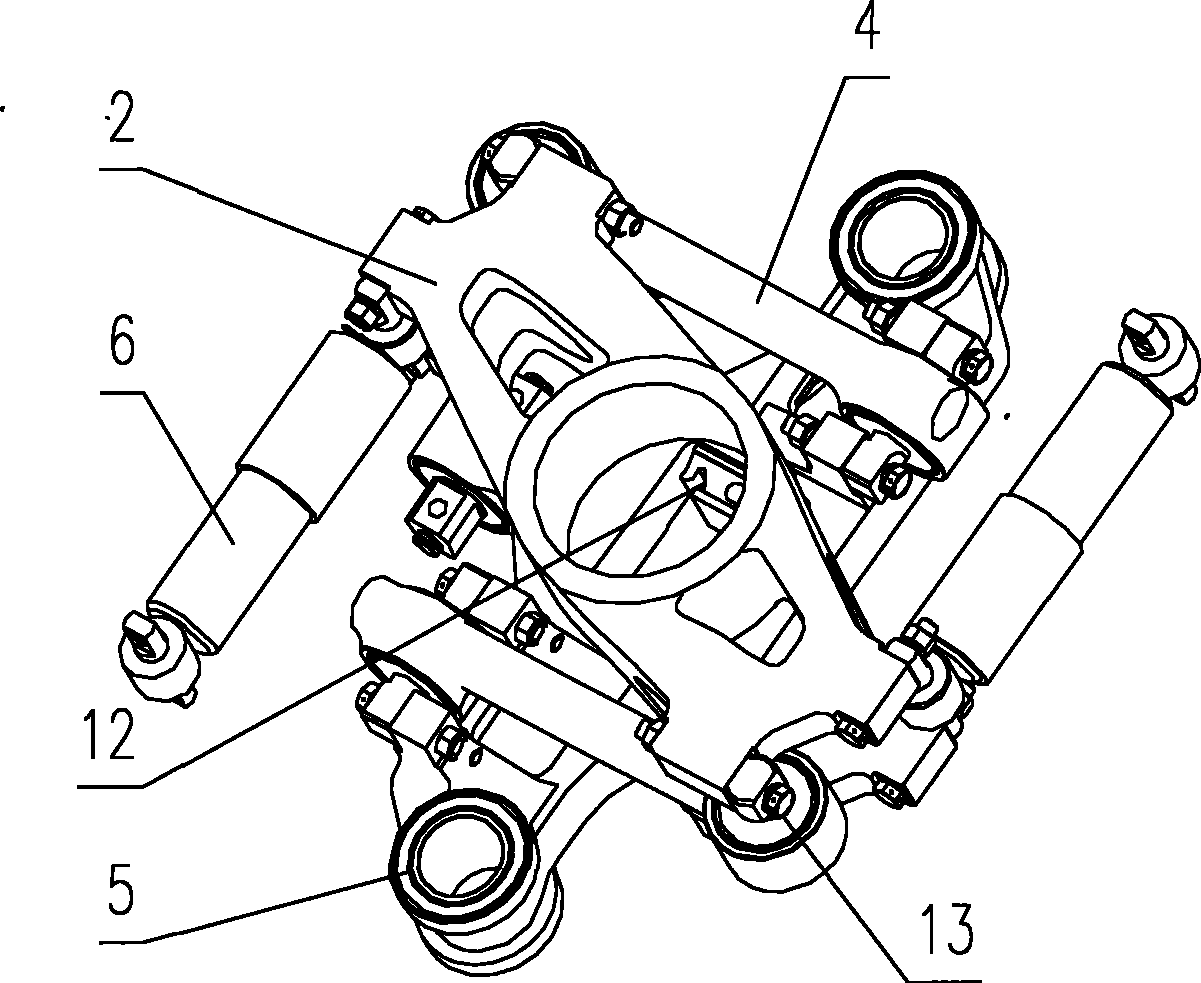

[0038] Example 1, such as Figure 1 to Figure 6 As shown, the central beam type traction device has a traction beam 2 , a longitudinal traction rod 3 , a traction rod 4 , and a central beam 5 . in,

[0039] Both ends of the central beam 5 are connected to the side beams of the bogie frame through elastic nodes 10 . The elastic node 10 is an integral structure made of rubber and metal vulcanized, which can provide the stiffness required by the design. By optimizing the longitudinal stiffness, the transmission of vibration between the traction device as a whole and the frame can be alleviated.

[0040] A longitudinal tie rod seat 8 for connecting the longitudinal pull rod 3 is arranged on the side of the central beam 5 . The longitudinal traction rod 3 has a pull rod body 15, and is connected to the linear motor through a traction joint 16 composed of metal and rubber at its end.

[0041] Two traction rod seats 7 for connecting the traction rods 4 are arranged on the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com