Production line for continuous-extrusion, continuous-rolling and temperature-control production of magnesium alloy products

A magnesium alloy, production line technology, applied in the direction of temperature control, metal rolling, etc., can solve the problems of wave, long production line, easy to warp and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

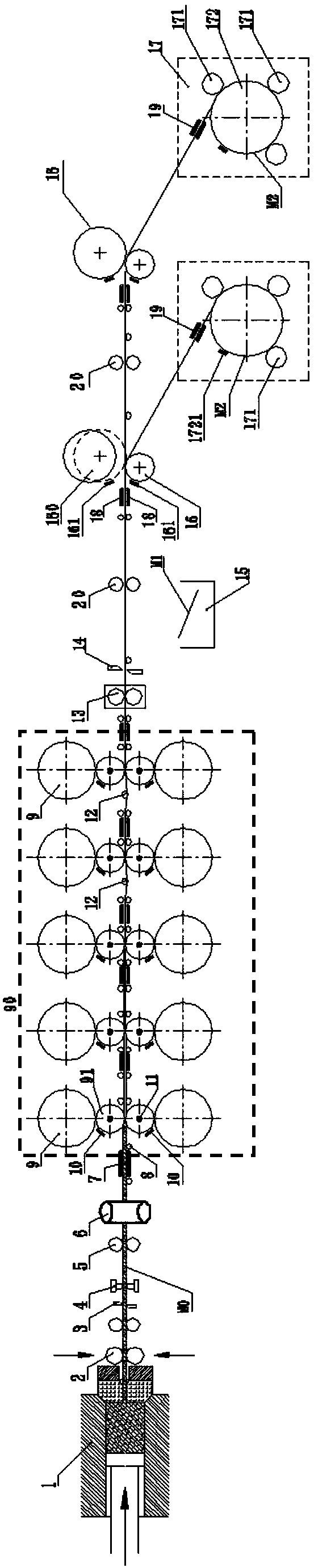

[0063] image 3 The structure of the production line for producing magnesium alloy products by continuous extrusion and continuous rolling with temperature control in the first embodiment is shown. Such as image 3 As shown, the production line for the production of magnesium alloy products by continuous extrusion and continuous rolling with temperature control in this embodiment sequentially includes: extruder 1, centering pinch roll 2, shearing machine 3, synchronous welding device 4, Tension pinch roll 5, vertical roll side press 6, strip heating device 7, heat transfer roll 8, multi-stand temperature-controlled continuous rolling mill 90, roll surface heating device 10, cooling water device 11, biting bevel angle adjustment Mechanism 12, slitting machine 13, flying shear 14, hopper 15, second strip heating device 18, eccentric pinch roller 16, first strip heating device 19, temperature-controlled coiler 17 and control unit.

[0064] In the production line for producing m...

Embodiment 2

[0079] Figure 4 The structure of the production line for producing magnesium alloy products by continuous extrusion and continuous rolling with temperature control in the second embodiment is shown. Such as Figure 4 As shown, the production line for the production of magnesium alloy products by continuous extrusion and continuous rolling with temperature control in this embodiment includes: extruder 1, centering pinch roll 2, shearing machine 3, tension pinch roll 5 from the direction of magnesium alloy feeding , vertical roll side press 6, strip heating device 7, heat transfer roll 8, multi-stand temperature-controlled continuous rolling mill 90, roll surface heating device 10, cooling water device 11, biting bevel angle adjustment mechanism 12, slitting Machine 13, flying shear 14, hopper 15, second strip heating device 18, eccentric pinch roller 16, first strip heating device 19, temperature-controlled coiler 17 and control unit.

[0080] The names of the parts in the s...

Embodiment 3

[0083] Figure 5 The structure of the production line for producing magnesium alloy products by continuous extrusion and continuous rolling with temperature control in Example 3 is shown. Such as Figure 5 As shown, the production line for the production of magnesium alloy products by continuous extrusion and continuous rolling with temperature control in this embodiment sequentially includes: extruder 1, centering pinch roll 2, shearing machine 3, synchronous welding device 4, Tension pinch roll 5, vertical roll side press 6, strip heating device 7, heat transfer roll 8, multi-stand temperature-controlled continuous rolling mill 90, roll surface heating device 10, cooling water device 11, biting bevel angle adjustment Mechanism 12, slitting machine 13, flying shear 14, second strip heating device 18, eccentric pinch roller 16, first strip heating device 19, temperature-controlled coiler 17 and control unit.

[0084] Since the name of each part in the third embodiment is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com