Silicon carbide micro-powder mixed material screening device

A technology of silicon carbide micropowder and screening device, which is applied in sieve, solid separation, chemical instruments and methods, etc., can solve the problem of silicon carbide micropowder sticking and blocking sieve, low utilization rate of sieve surface, and automatic sieving effect of sieve surface. Poor and other problems, to avoid sticking and blocking screens, improve accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

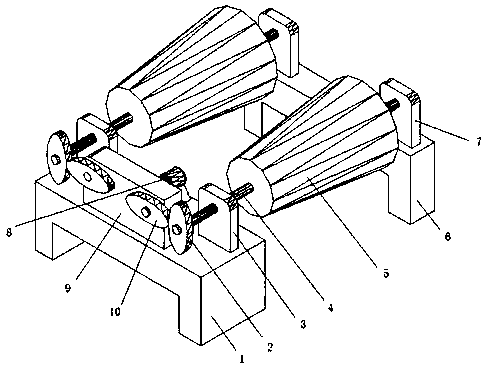

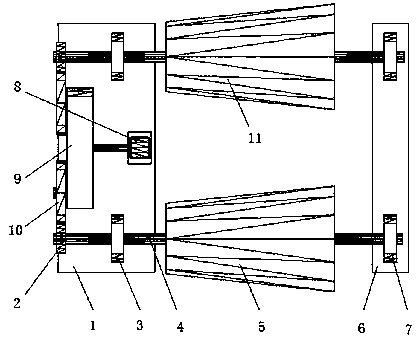

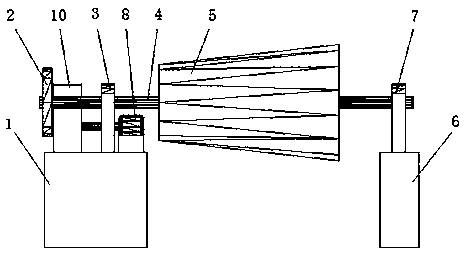

[0016] Such as Figure 1 to Figure 3 As shown, a silicon carbide powder mixing and screening device includes a left base 1, a right base 6, a drive motor 8, a speed reduction device 9, and a screening cylinder. The drive motor 8 and the speed reduction device 9 are fixed on the left base 1 , And the output shaft of the drive motor 8 is connected with the input shaft of the deceleration device 9 by a coupling. The cylindrical working surface of the screening cylinder is provided with sieve holes, one end is provided with a feed port, and the other end is provided with a coarse grain outlet. The material port, the left base 1 is symmetrically provided with two left support seats 3, and the right base 6 is symmetrically provided with two right support seats 7 corresponding to the positions of the two left support seats 3, and the two left support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com