Automatic machining equipment of starch and grinding and screening technology thereof

An automatic processing and screening technology, applied in the field of starch processing, can solve the problems of high labor intensity, low work efficiency, affecting human health, etc., and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

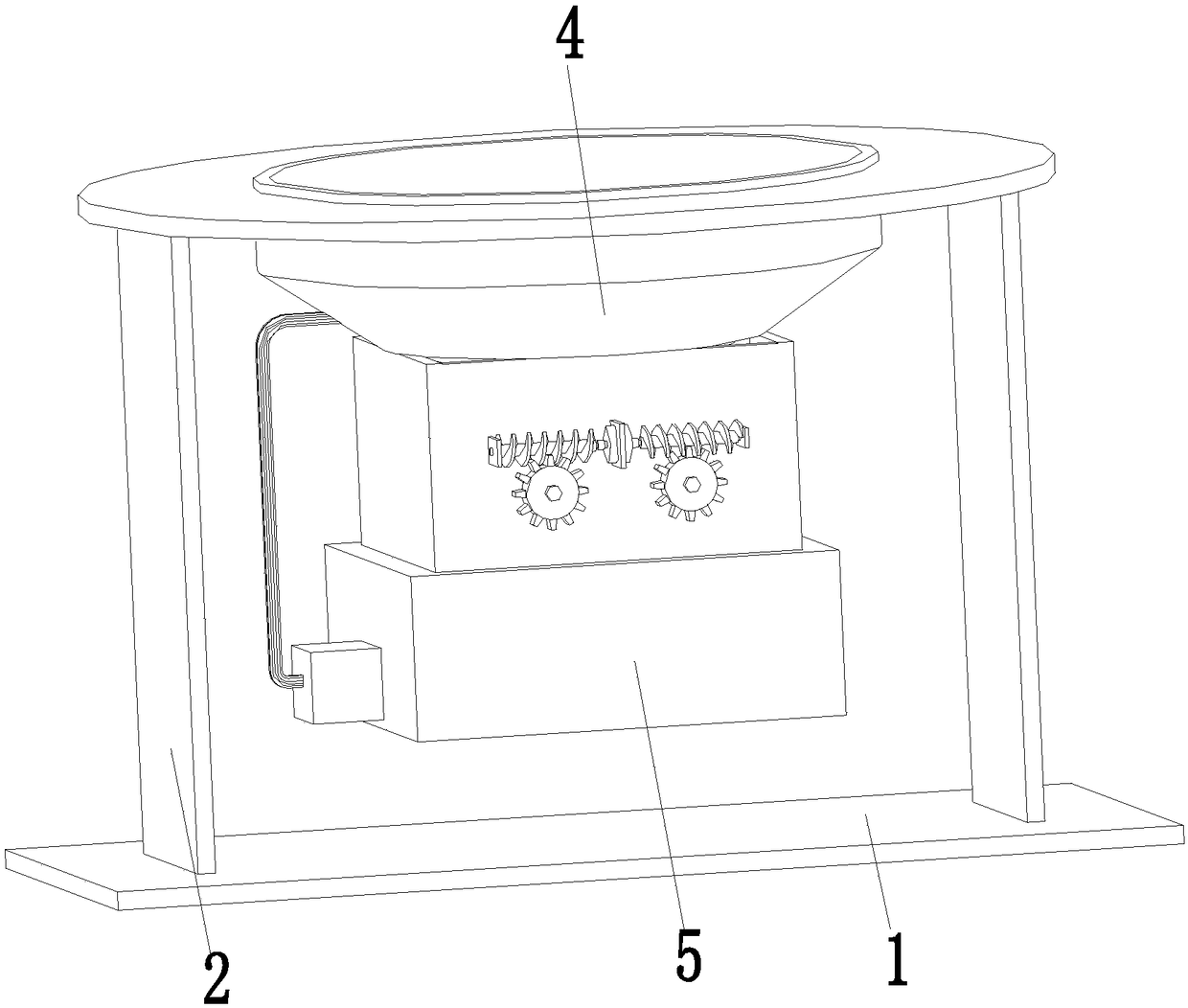

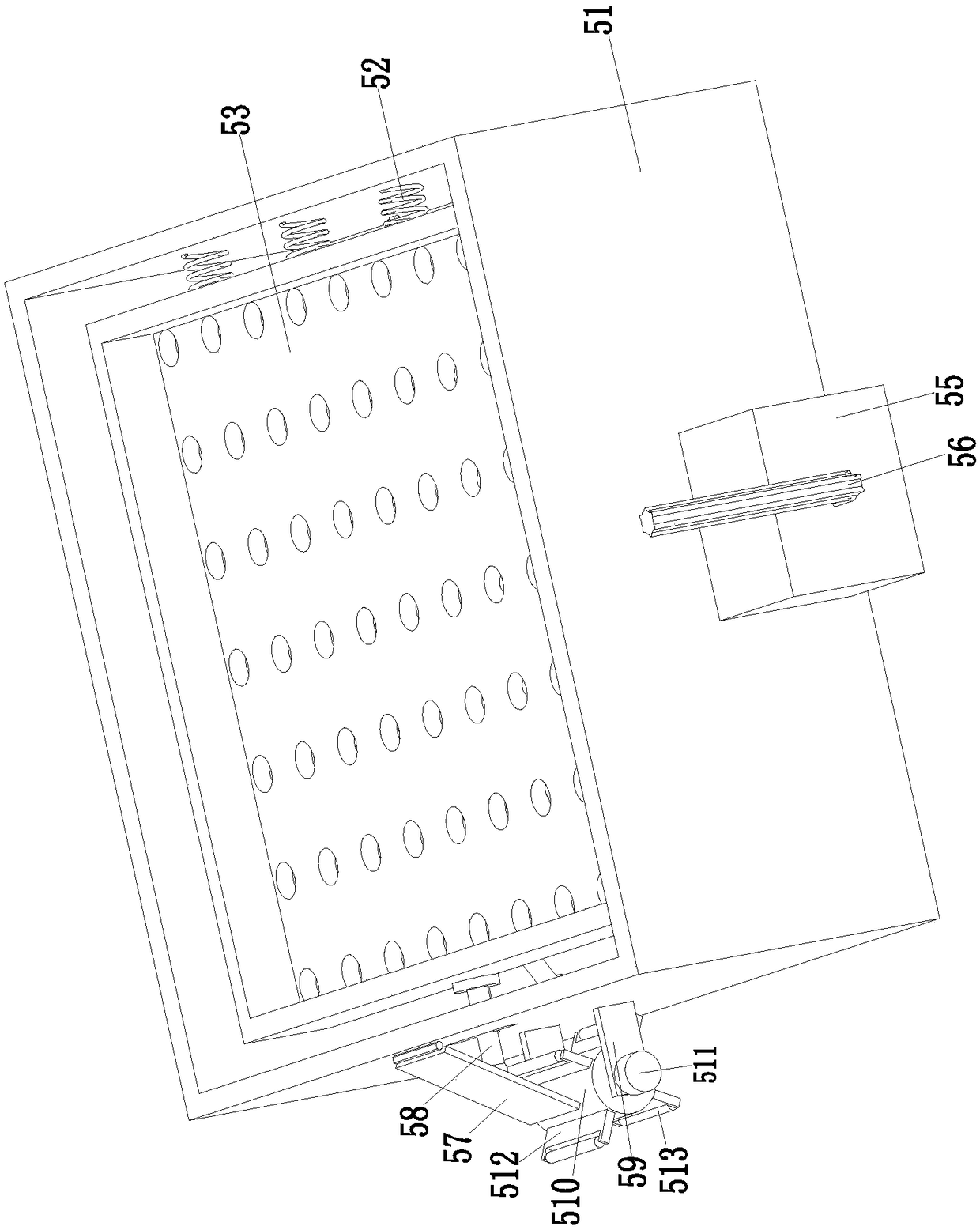

[0023] Such as Figure 1 to Figure 5 As shown, an automatic starch processing equipment includes a bottom plate 1, a fixed support frame 2 is installed on the bottom plate 1, a grinding device 4 is installed on the fixed support frame 2, and a screening device 5 is installed at the lower end of the grinding device 4.

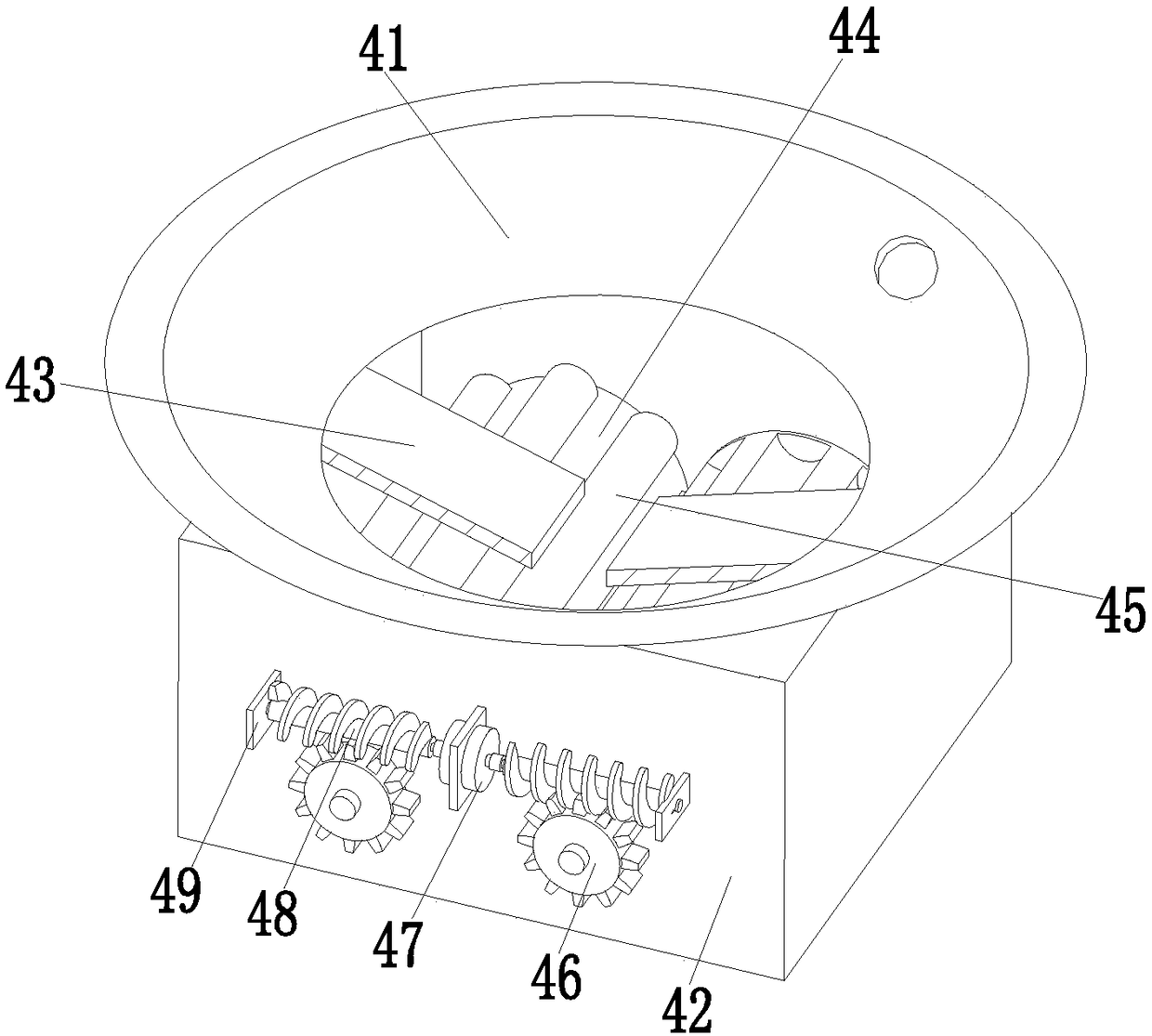

[0024]Described grinding device 4 comprises the grinding guide cavity 41 that is installed on the fixed support frame 2, and grinding guide cavity 41 is provided with grinding inlet, and the lower end of grinding guide cavity 41 is equipped with grinding operation cavity 42, and grinding operation cavity The inner wall of 42 is provided with two grinding guide plates 43, and the two grinding guide plates 43 are symmetrically locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com