drive unit

A technology of driving device and control device, which is applied in the direction of power device, electrical device, control drive, etc., can solve the problem of increased energy consumption of the braking mechanism, and achieve the effects of simplifying control, improving responsiveness, and suppressing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

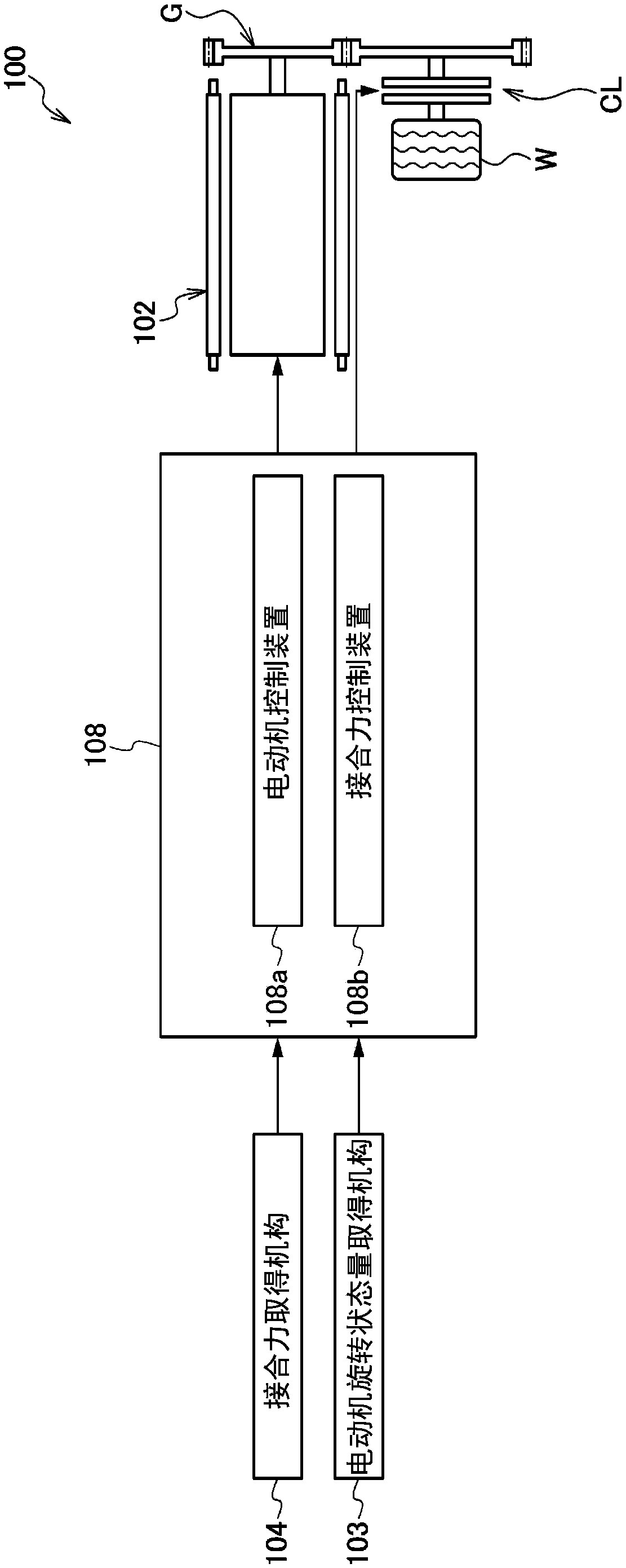

[0091] Such as figure 1 As shown, the driving device 100 of the first embodiment has a motor 102 and a clutch CL provided on a power transmission path between the motor 102 and the wheels W as a power transmission mechanism. The clutch CL is a hydraulic clutch, and is configured to be able to change the engagement force to change the power transmission capacity of the power transmission path.

[0092] The control device 108 of the driving device 100 includes a motor control device 108 a that controls the torque generated by the electric motor 102 and an engagement force control device 108 b that controls the engagement force of the clutch CL.

[0093] The engagement force control device 108b that controls the engagement force of the clutch CL can adjust the engagement force of the clutch CL by adjusting the rotation speed of the oil pump or adjusting the hydraulic pressure of the hydraulic circuit.

[0094] A motor control device 108 a that controls the torque generated by th...

no. 2 approach

[0111] The drive device 1 of the second embodiment uses an electric motor as a drive source for driving an axle, and is used, for example, in image 3 The drive system of the vehicle is shown. In the following description, a case where the driving device is used for driving the rear wheels will be described as an example, but the driving device may also be used for driving the front wheels.

[0112] image 3 The illustrated vehicle 3 is a hybrid vehicle having a driving device 6 (hereinafter referred to as a front-wheel drive device) in which an internal combustion engine 4 and an electric motor 5 are connected in series at the front of the vehicle, and the power of the front-wheel drive device 6 is transmitted via a transmission device. 7 is transmitted to the front wheels Wf, and on the other hand, the power of the driving device 1 (hereinafter referred to as the rear wheel driving device) provided in the rear of the vehicle separately from the front wheel driving device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com