Iron core and disk type motor

A disc motor and iron core technology, applied in the field of motor parts, can solve problems such as high energy consumption and high current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

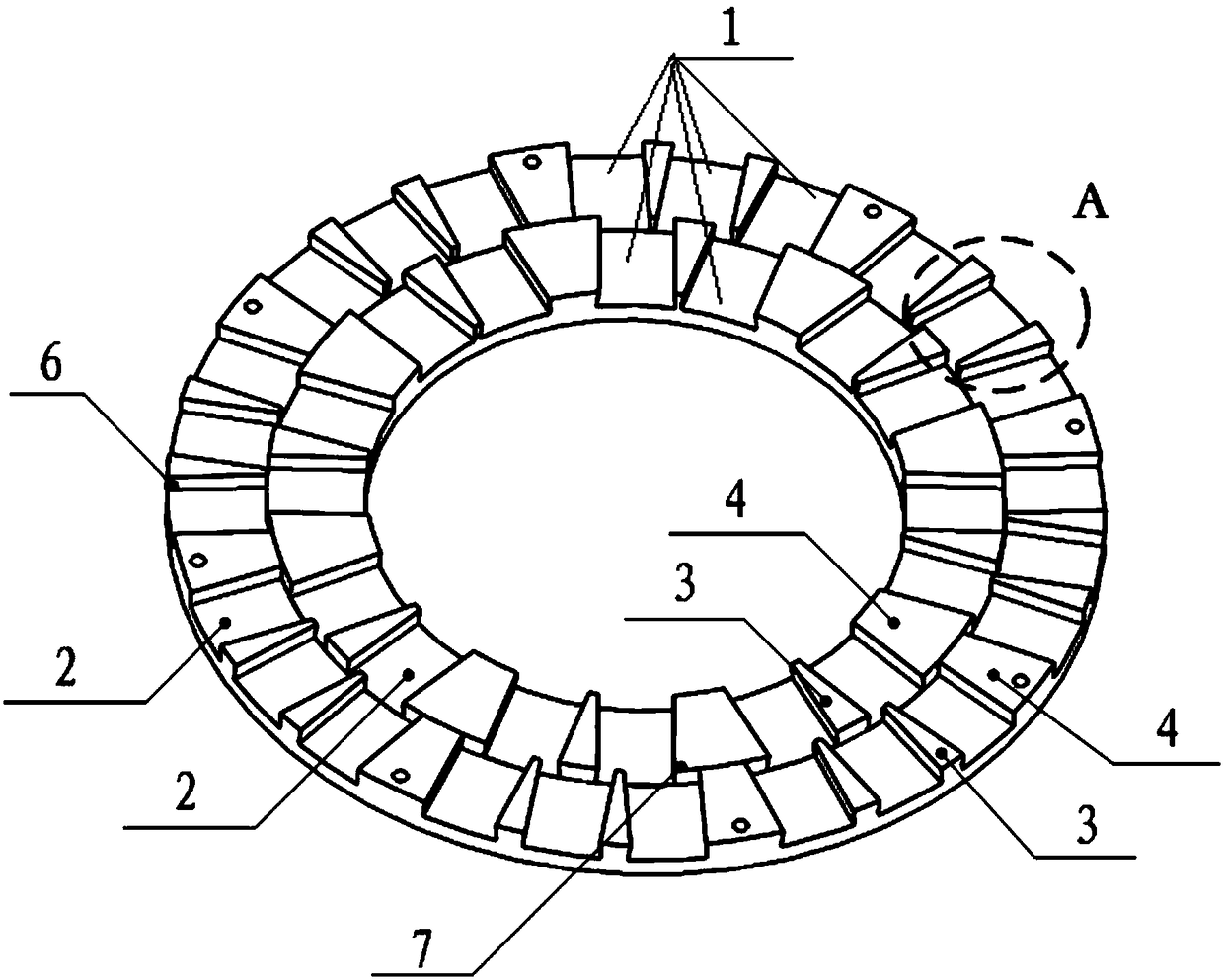

[0048] Such as Figure 1-6 As shown, the present invention provides an iron core. It can be used in the middle stator, two side rotors or single stator, single rotor or cascaded disc motor structure.

[0049] Wherein, multiple groups of magnetic steel installation positions 1 are evenly distributed along the circumferential direction of the iron core on the iron core.

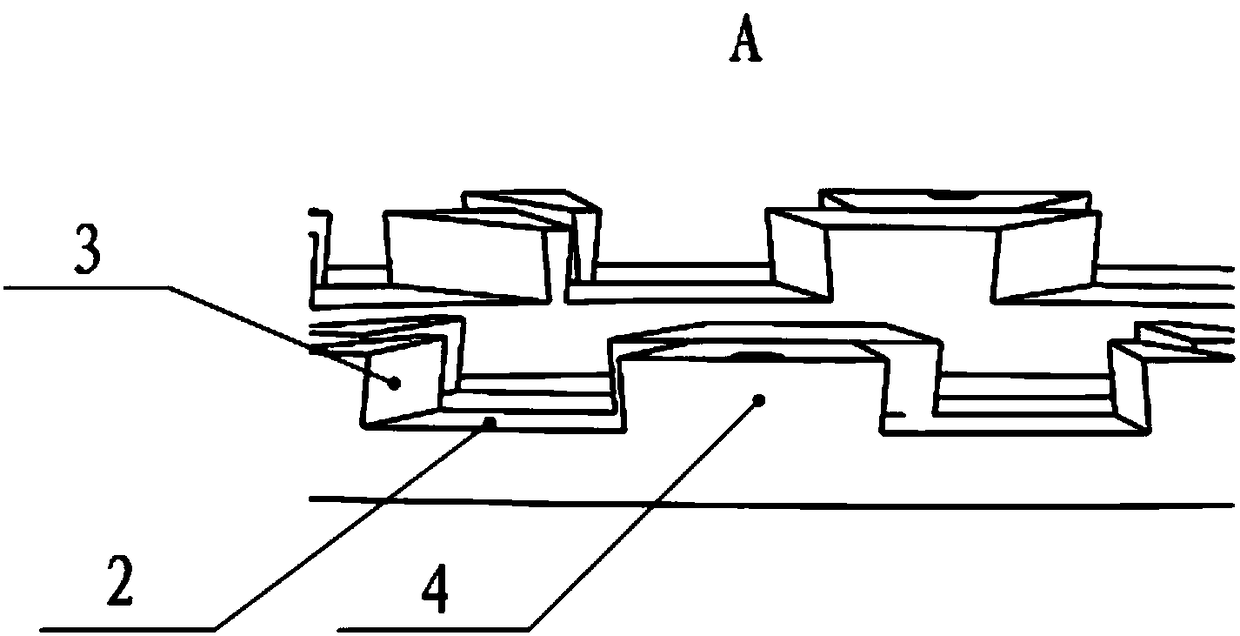

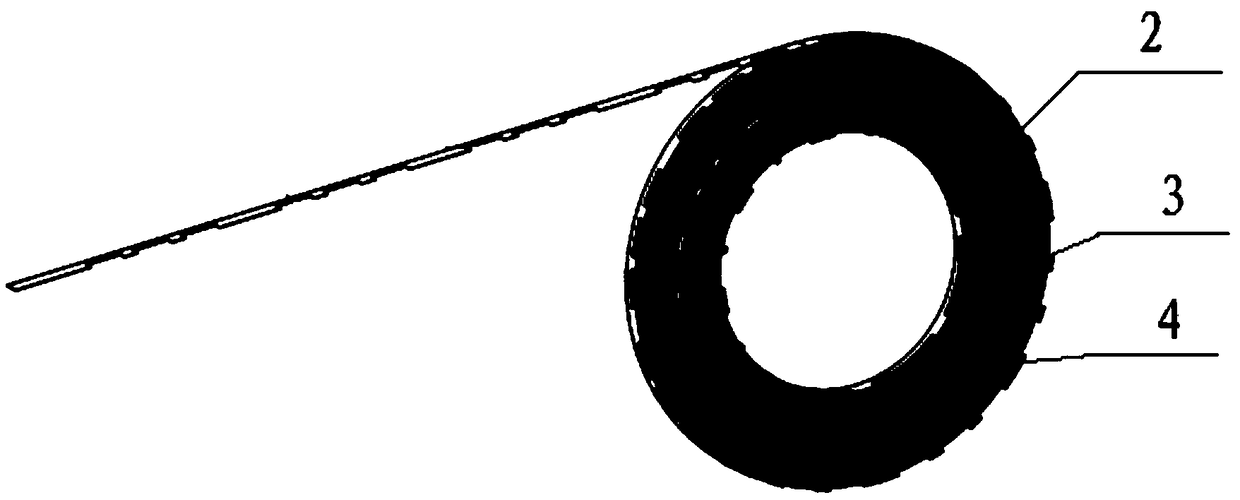

[0050] Each group of magnetic steel installation positions 1 includes a plurality of steel grooves 2 for installing magnetic steel 5 . And along the circumferential direction of the iron core, the first iron core teeth 3 are arranged between the adjacent steel grooves 2 of the same group of magnetic steel installation positions 1, and the steel grooves 2 of the same group of magnetic steel installation positions 1 are used to install the same Magnetic poles of magnetic steel 5.

[0051] The second iron core teeth 4 are arranged between adjacent groups of magnetic steel installation positions 1, and the steel...

Embodiment 2

[0056] In the second embodiment provided by the present invention, the structure of the iron core in this embodiment is similar to the iron core in the first embodiment, so the similarities will not be repeated, and only the differences will be introduced.

[0057] In this embodiment, the present invention specifically discloses that along the axial direction of the iron core, the thickness of the second iron core teeth 4 is greater than the thickness of the first iron core teeth 3 .

[0058]The second iron core tooth 4 on the iron core can increase the q-axis inductance of the motor (the inductance is proportional to the magnetic permeability of the magnetic field loop, and the magnetic flux path that generates the q-axis inductance needs to pass through the middle axis between adjacent magnetic poles of different polarities , because the second iron core tooth 4 is located on the magnetic flux path, therefore, the magnetic permeability of the magnetic field circuit can be inc...

Embodiment 3

[0075] The present invention provides a disc motor, including a magnetic steel 5 and an iron core as in any one of the above-mentioned embodiments. The magnetic steel 5 is installed in the steel groove 2 of the iron core.

[0076] Since the disc motor disclosed in the present invention includes the iron core in any one of the above embodiments, all the beneficial effects of the iron core are included in the disc motor disclosed in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com