Device of fiber optics bundles penetrating quartz capillary and penetrating method thereof

A technology of quartz capillary and multiple optical fibers, applied in the field of beam combiners, can solve the problems of low success rate and easy to be polluted by dust, and achieve the effect of improving the success rate and reliable guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

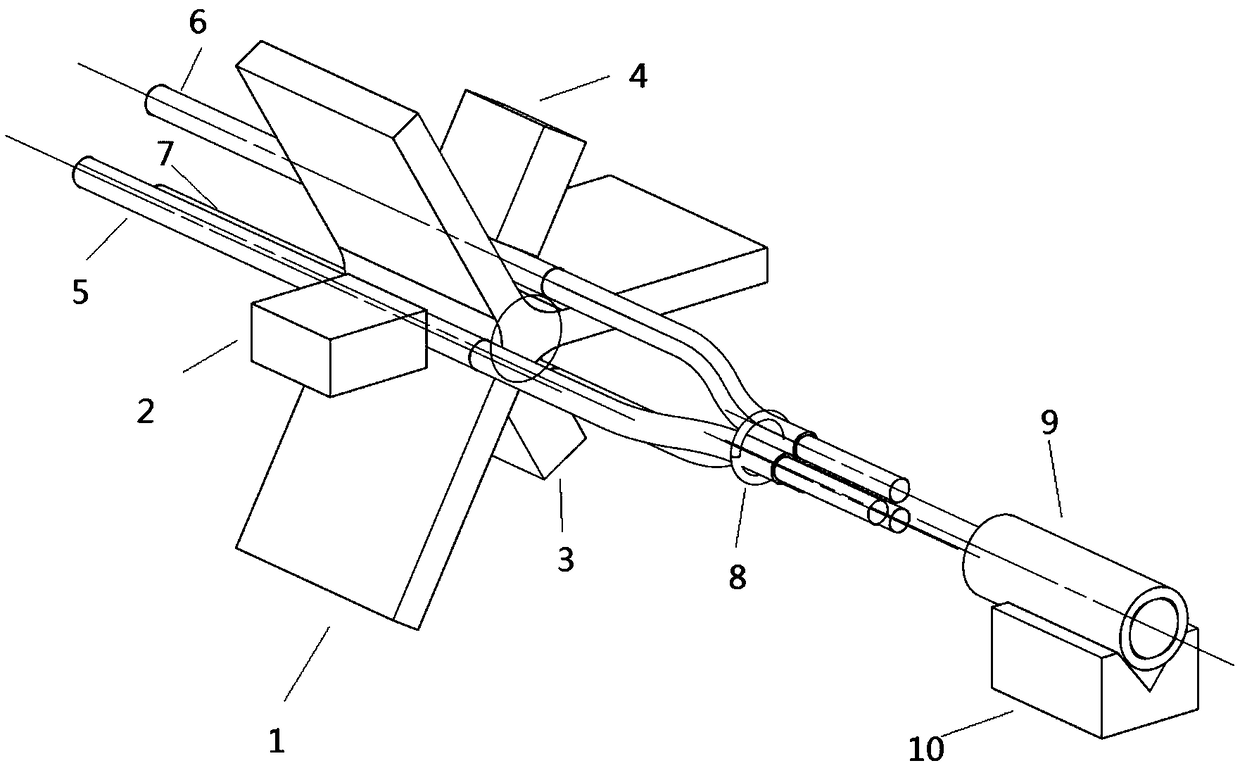

[0027] see first figure 1 , figure 1 It is a schematic diagram of a device in which three optical fiber bundles are inserted into a capillary in Example 1 of the present invention. As can be seen from the figure, the device for fast penetration of multiple optical fiber bundles into capillaries of the present invention includes an optical fiber bundle positioning fixture 1, an annular pre-constrained fixture 8, a quartz capillary 9 and a linear displacement platform, and the optical fiber bundle positioning fixture 1 consists of a uniform Three distributed V-shaped clamping grooves and one-to-one corresponding three fixed pressing blocks 2, 3, 4 are formed. The ring-shaped clamping part of the annular pre-constraint fixture 8 reserves three optical fibers into an optical fiber bundle. The quartz capillary 9 is positioned in the V-groove of the V-groove capillary clamp 10, the quartz capillary 9 is fixed on the linear displacement platform through the V-groove fixed capillary ...

Embodiment 2

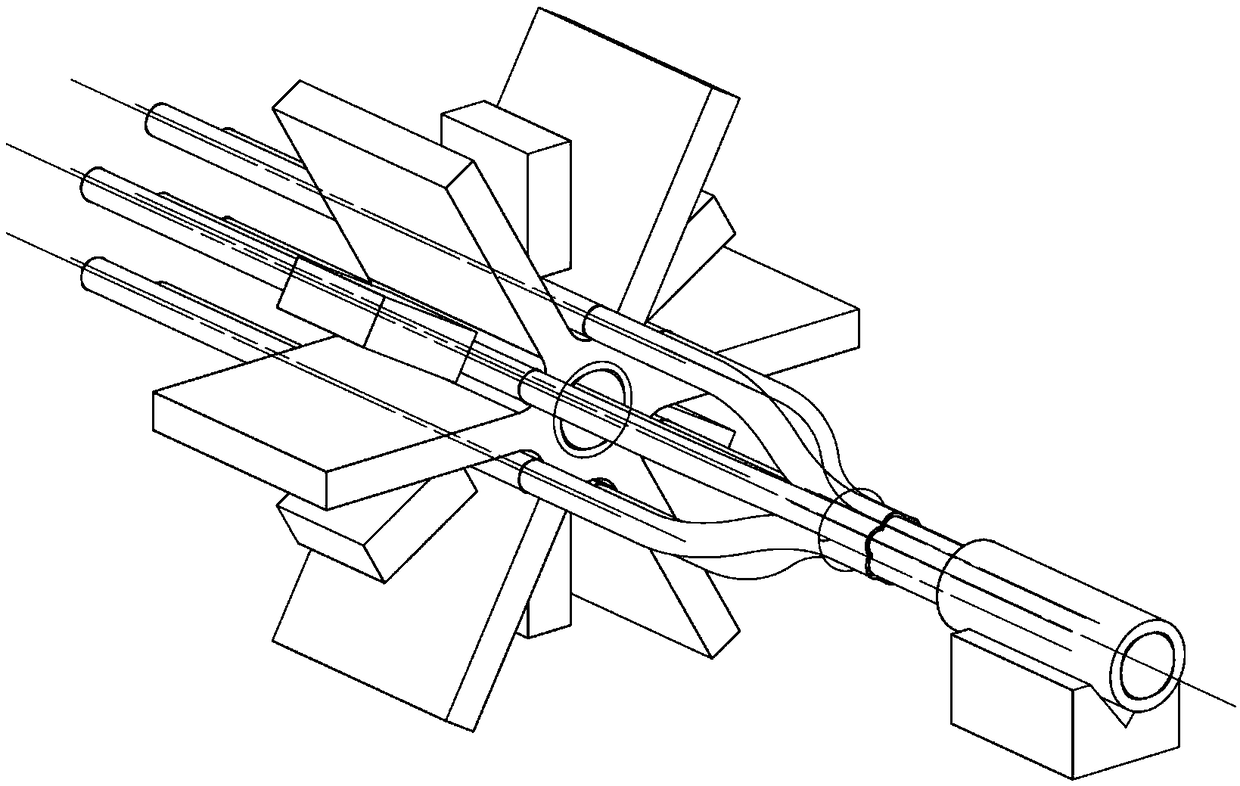

[0037] see figure 2 , Figure 4 and Figure 6 , the method of embodiment 2 is as follows:

[0038] 1) First remove the coating layer at one end of the seven optical fibers to form the end of the bare optical fiber, and then place multiple optical fibers in sequence in the V-shaped clamping groove in the optical fiber positioning fixture 1 for clamping;

[0039] 2) The ends of the bare optical fibers are pre-constrained by the ring-shaped clamping part of the annular pre-constraint fixture 8, so that the outer diameters of the ends of the bare optical fiber bundles are tangent, and closely arranged to form a uniformly arranged circular optical fiber bundle;

[0040] 3) The quartz capillary 9 is positioned in the V-groove of the V-groove positioning fixture 10, and the quartz capillary 9 is fixed on the linear displacement platform by the V-groove positioning fixture 10. The laser beam adjustment tool, the centerlines of the optical fiber positioning fixture 1, the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com