Closed dehumidification water-water heat pump drying system with multiple drying rooms

A drying system and water heating technology, applied in the field of drying system, can solve problems such as failure to meet process requirements, poor quality of dried materials, and increased energy consumption of the unit, so as to reduce initial investment costs, reduce labor intensity, and improve The effect of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

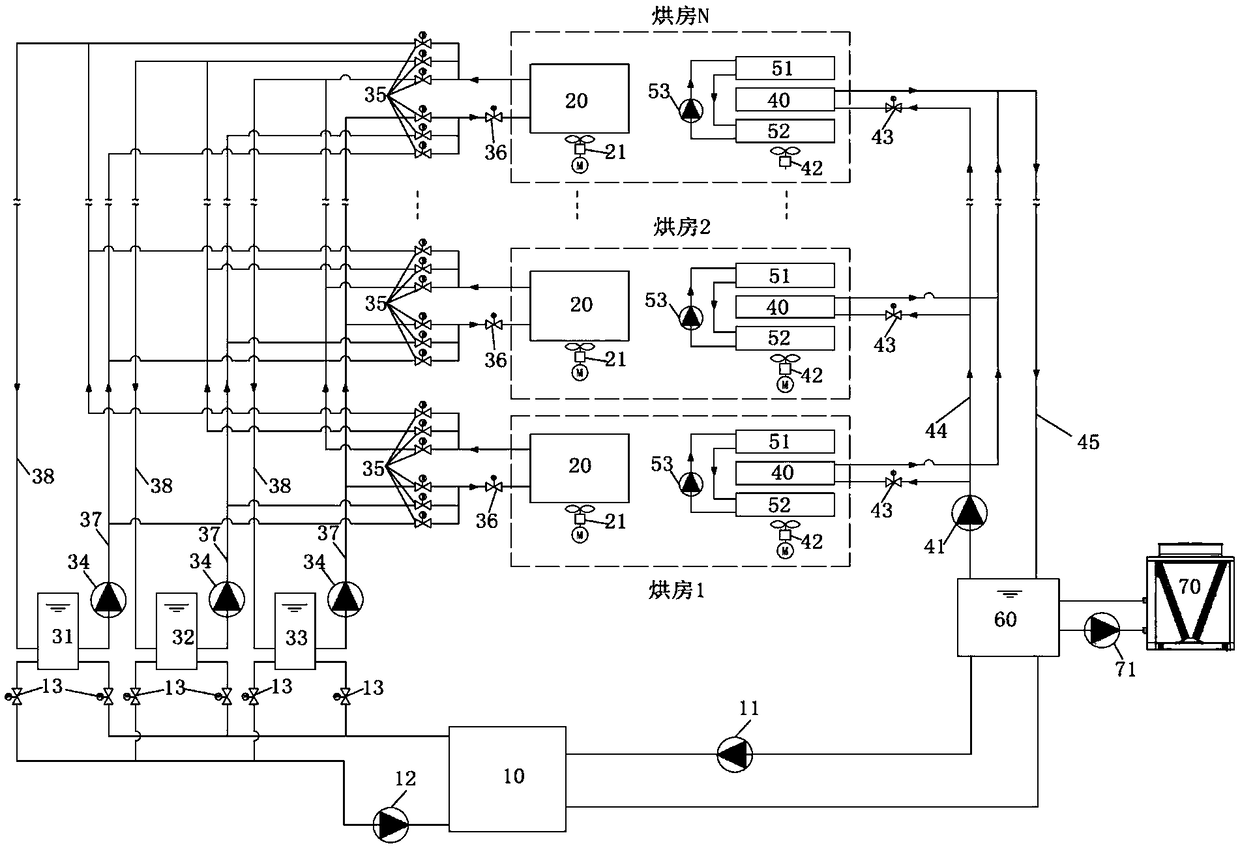

[0022] Example: such as figure 1 As shown, a closed dehumidification water-water heat pump multi-drying room drying system includes a water-water heat pump 10, a hot water tank, an energy storage water tank 60 and several drying rooms, each of which is provided with a heating coil 20, Heating axial flow fan 21, dehumidification coil 40 and dehumidification fan 42, the heating axial flow fan 21 is used to drive the air to be heated through the heating coil 20, and the dehumidification fan 42 is used to drive the air to pass through the dehumidification coil 40 for dehumidification, so The hot water generated by the water-to-water heat pump 10 enters the hot water tank through the pipeline, and the hot water on one side of the hot water tank is pumped into the heating coil 20 by the heating water pump 34 through the heating water pipeline 37, and the hot water passes through the heating coil 20 After heat exchange, return to the hot water tank through the first return water pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com