A pre-pump oil-water separation single-unit double-pump injection-production system

An oil-water separation and unit technology, which is applied to pumps, pump devices, and production fluids, etc., can solve the problems of poor oil-water separation effect, complicated process, and unfavorable oil-water separation in downhole, and achieve the effect of increasing the processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

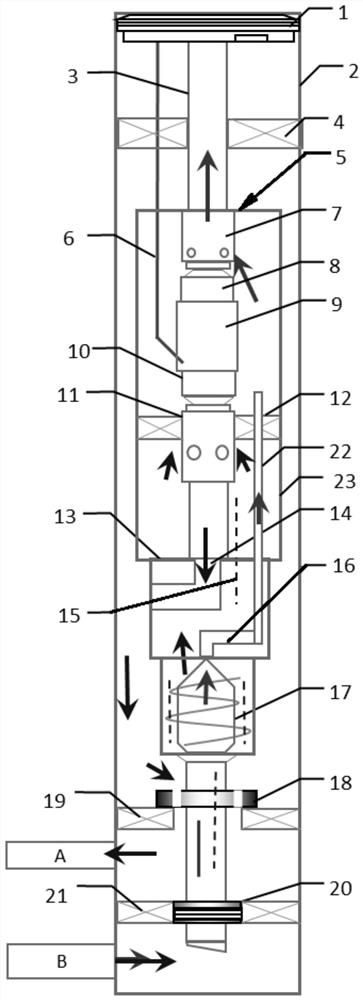

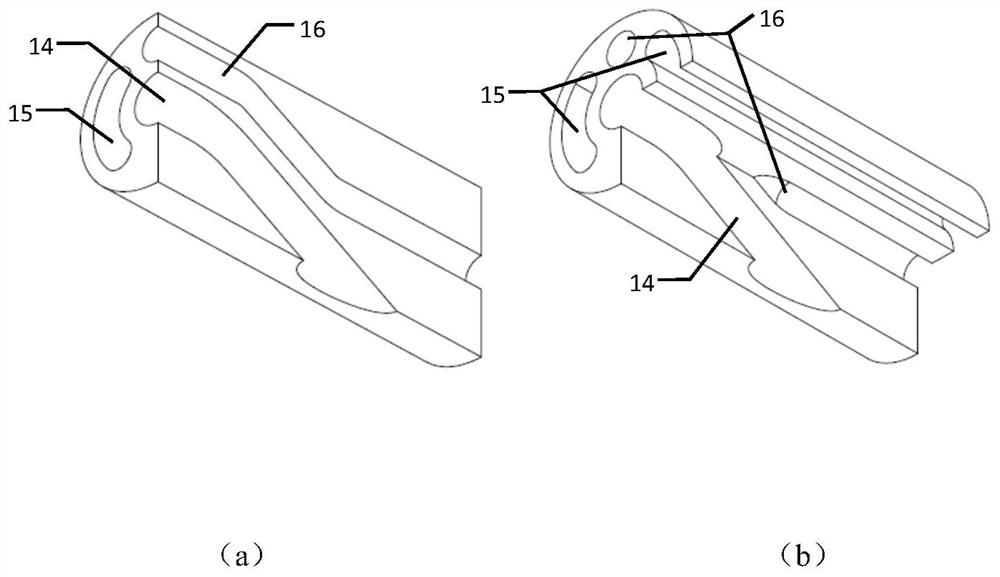

[0026] Such as figure 1 As shown, the pre-pump oil-water separation single-unit double-pump injection-production system of the present invention includes a casing 2 and a production string nested from outside to inside, and an oil pipe is arranged between the upper end of the production string and the casing 2 Hanging 1, the production string includes a cable packer 4, a canned electric pump injection production system 5, an oil-water separation and re-injection device 13, an oil-water separator 17, and an upper packing 19 and the lower packer 21. The upper packer 19 is provided with a positioning bypass 18, and the lower packer 21 is provided with an insertion seal 20, and the lower packer 21 and the insertion seal 20 separate the production layer B from the water injection layer A, Through the upper packer 19 and the positioning bypass 18, the positioning of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com