Waterway control assembly and method for rope core drilling rig

A waterway control and wireline coring technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high labor intensity and personnel costs, and long auxiliary time for waterway control, so as to shorten the auxiliary operation time and reduce the drilling time. Field staffing, the effect of reducing staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

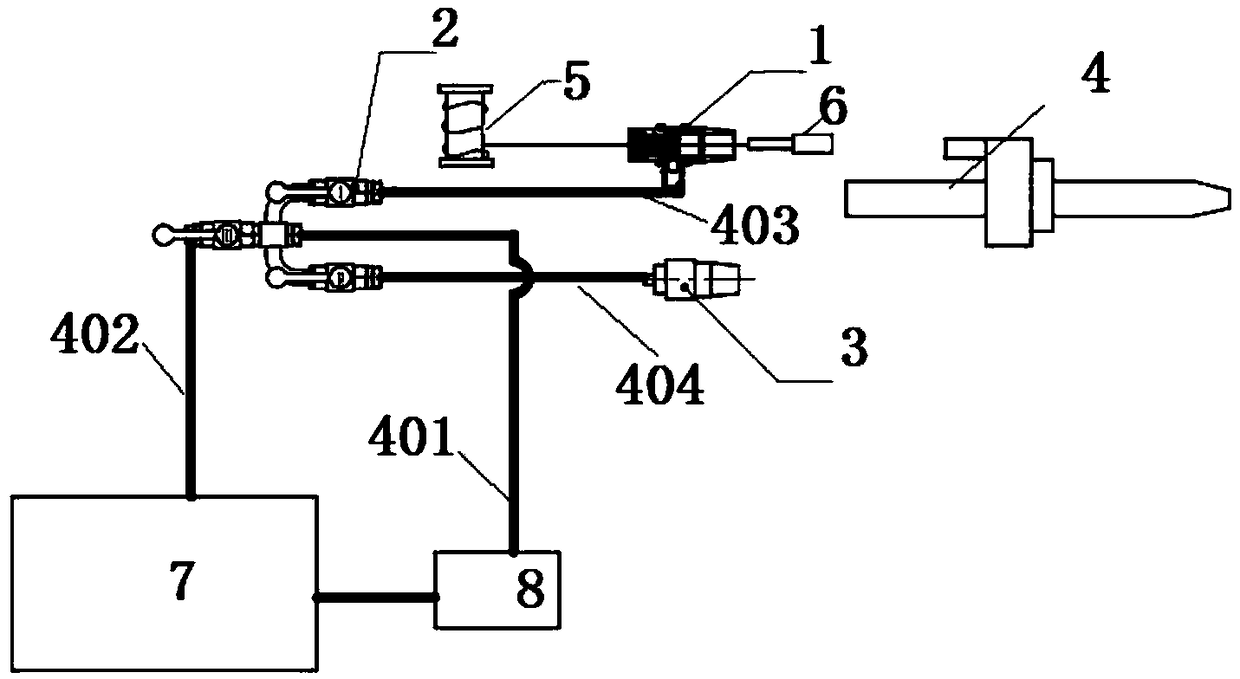

[0037] See figure 1 , Shows the structural schematic diagram of the waterway control assembly of the rope core drilling rig of the present invention.

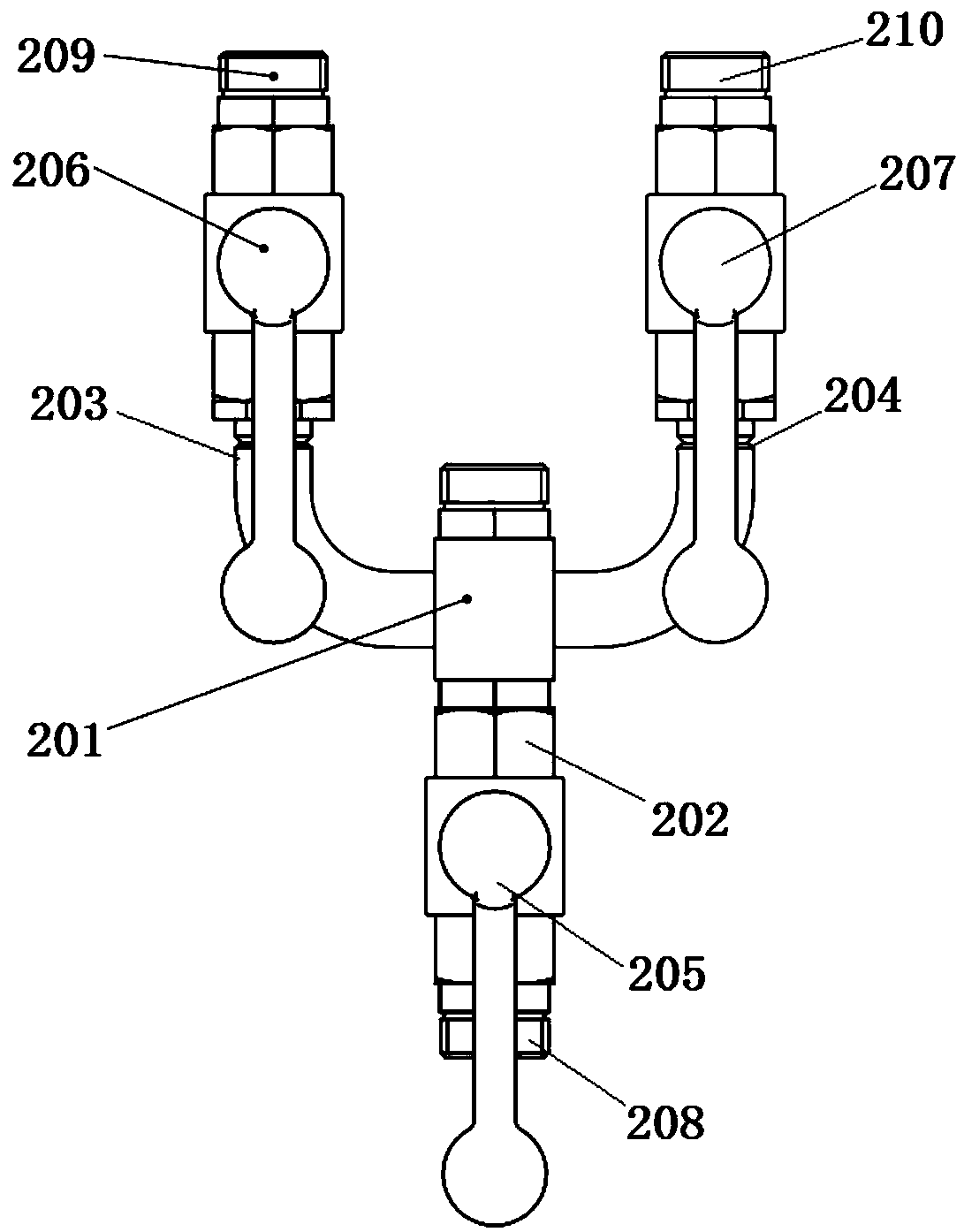

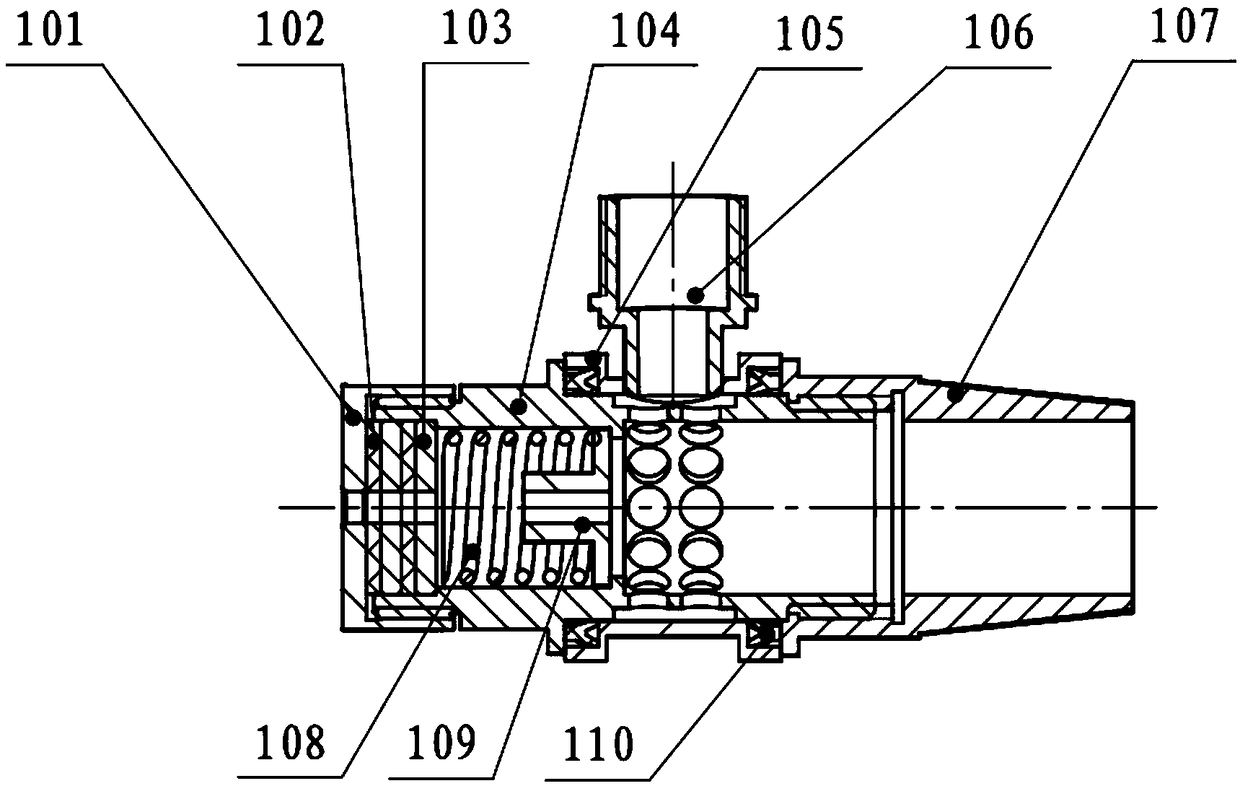

[0038] The waterway control assembly of the rope core drilling rig includes a rotatable cable water joint 1, a waterway control valve set 2, a conventional water joint 3, and a connecting pipeline. The waterway control valve set 2 includes a first interface 201 and a second interface 202. , The third interface 203 and the fourth interface 204, the connecting pipeline includes a water inlet pipe 401, a drain pipe 402, a cable water joint connection pipe 403 and a conventional water joint connection pipe 404, wherein one end of the water inlet pipe 401 and The first port 201 is connected, and the other end is connected to the water outlet of the mud pump 8, one end of the drain pipe 402 is connected to the second port 202, and the other end is directly connected to the pool 7; the cable water joint connection pipe 403 One end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com