Drilling and punching automatic switching device for preventing and controlling gas outburst, and gas outburst prevention method

An automatic switching, gas outburst technology, applied in gas discharge, safety devices, earth-moving drilling, etc., can solve the problems of time-consuming and laborious replacement process, hole plugging, and small amount of coal flushed out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

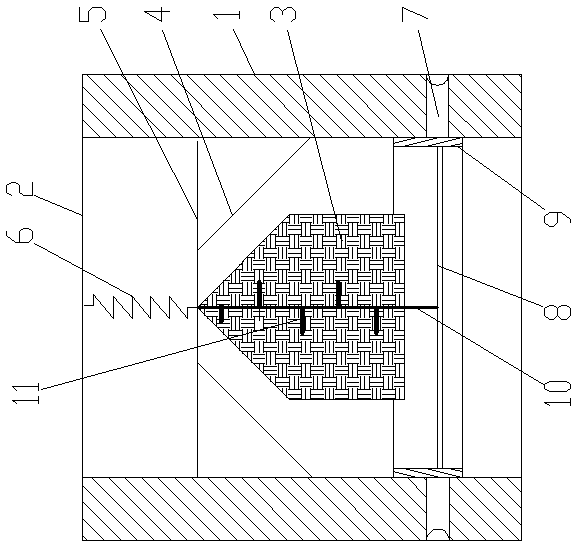

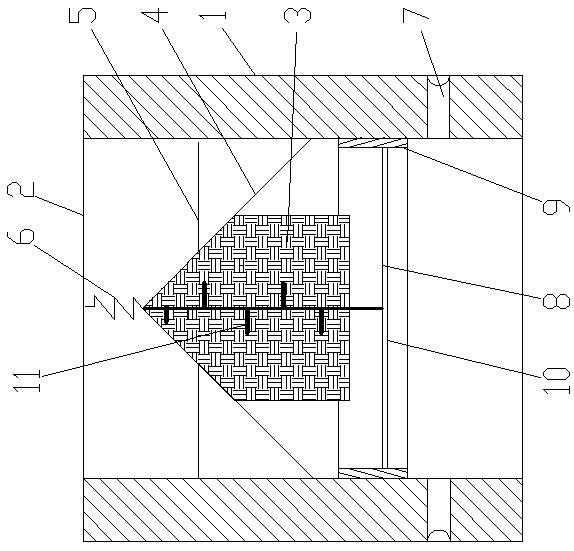

[0023] Such as figure 1 and figure 2 As shown, the automatic drilling punch switch device for preventing gas outburst of the present invention, the described automatic drill punch switch device for preventing gas outburst is arranged at the end of the drill pipe 1 on which the drill bit is installed, including a fixed rod 2, a tapered plug 3 and a circular platform The cylinder 4 and the fixed rod 2 are fixed in the drill pipe 1 along the horizontal direction. The shape of the circular table cylinder 4 is a conical structure with a small top and a large bottom, and the top and bottom are open. The circular table cylinder 4 is fixedly connected to the drill pipe 1 through the mounting frame 5. Inside, the circular platform tube 4 is located below the fixed rod 2, the bottom edge of the circular platform tube 4 is fixed on the inner wall of the drill pipe 1, the conical plug 3 is connected below the fixed rod 2 through a spring 6, the conical plug 3 is located in the circular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com