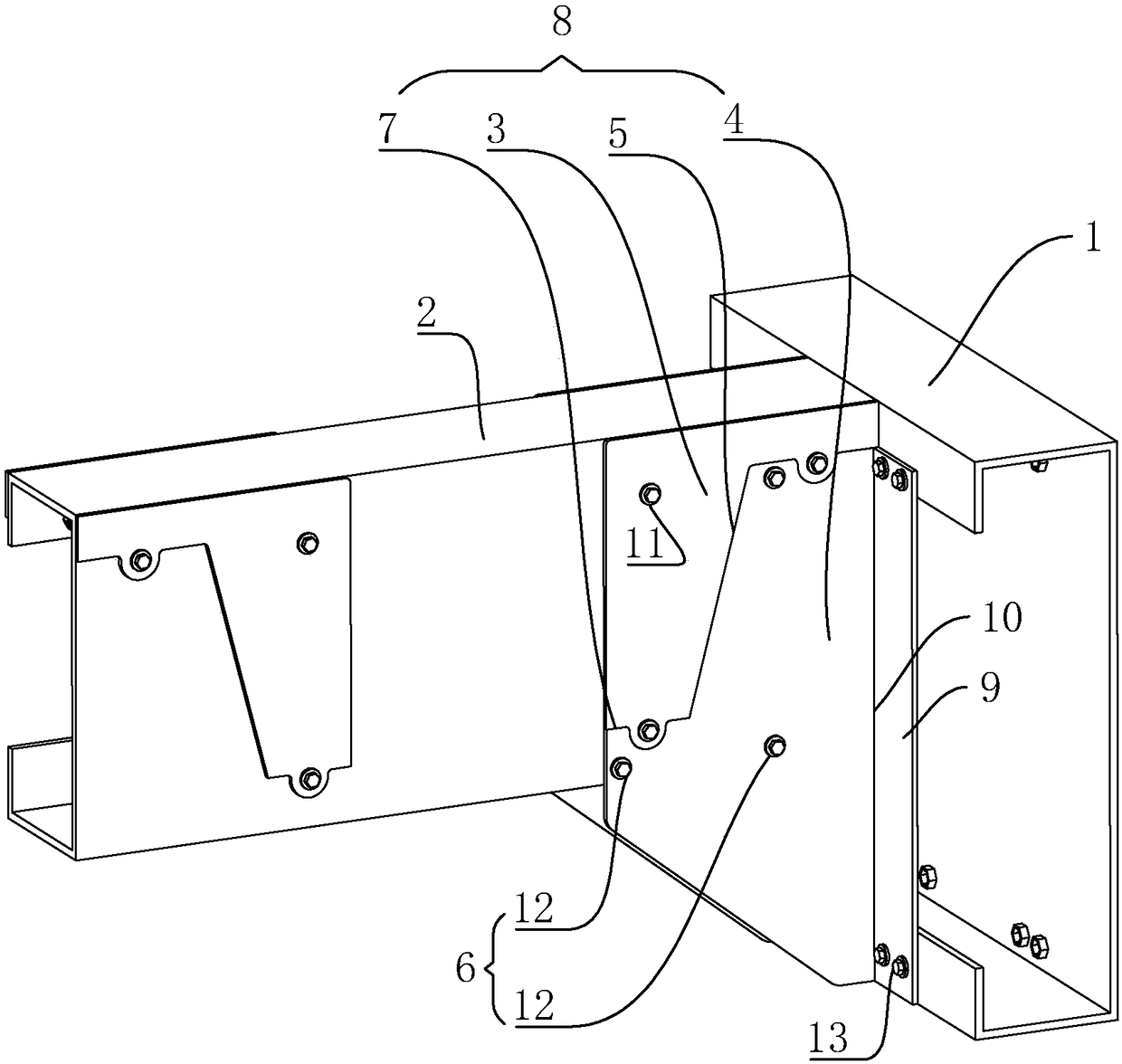

Quick mounting structure for steel structure

A technology of steel structure and connection device, which is applied in the direction of building structure and construction, and can solve problems such as deformation, large connection error between the main beam and the secondary beam, and deflection of the main beam, so as to ensure the construction time and the connection structure is simple , clear force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

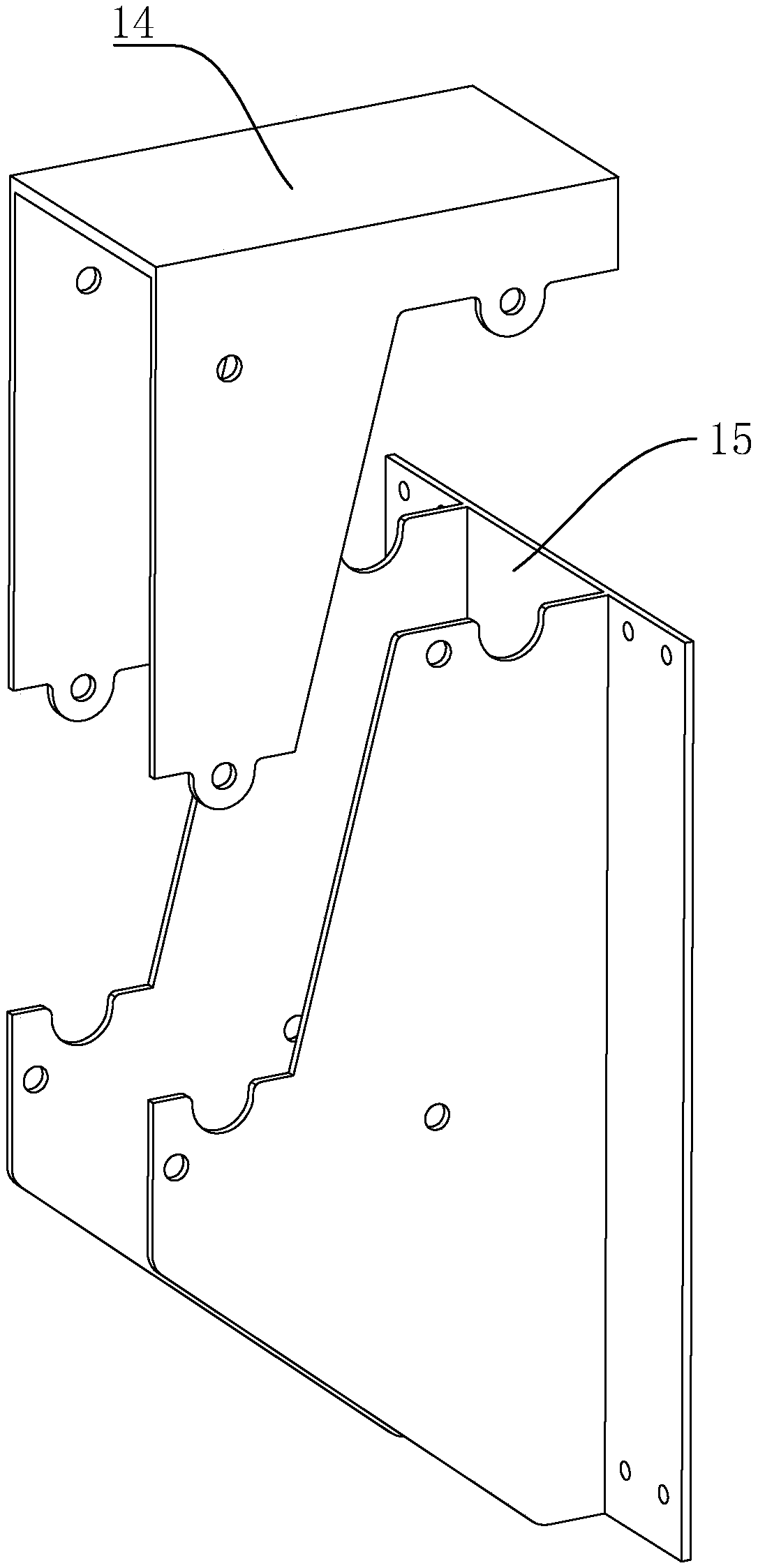

[0047] Another preferred embodiment: the difference from the first preferred embodiment is that, as image 3 As shown, the side of the two support plates 4 facing away from the lug 9 is integrally connected with a side plate 14 , and the side plate 14 and the lug 9 are in the same plane; the tops of the two connecting plates 3 are integrally connected with a top plate 15 . After providing the supporting plate 4 and the connecting plate 3 integrally arranged, the relative width between the two supporting plates 4 is determined, and the position control is more precise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com