Unmanned automatic production equipment for wool-like nylon filament

A technology for producing equipment and filaments, which is applied in the field of unmanned automated production equipment and can solve problems such as the inability to achieve wool bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

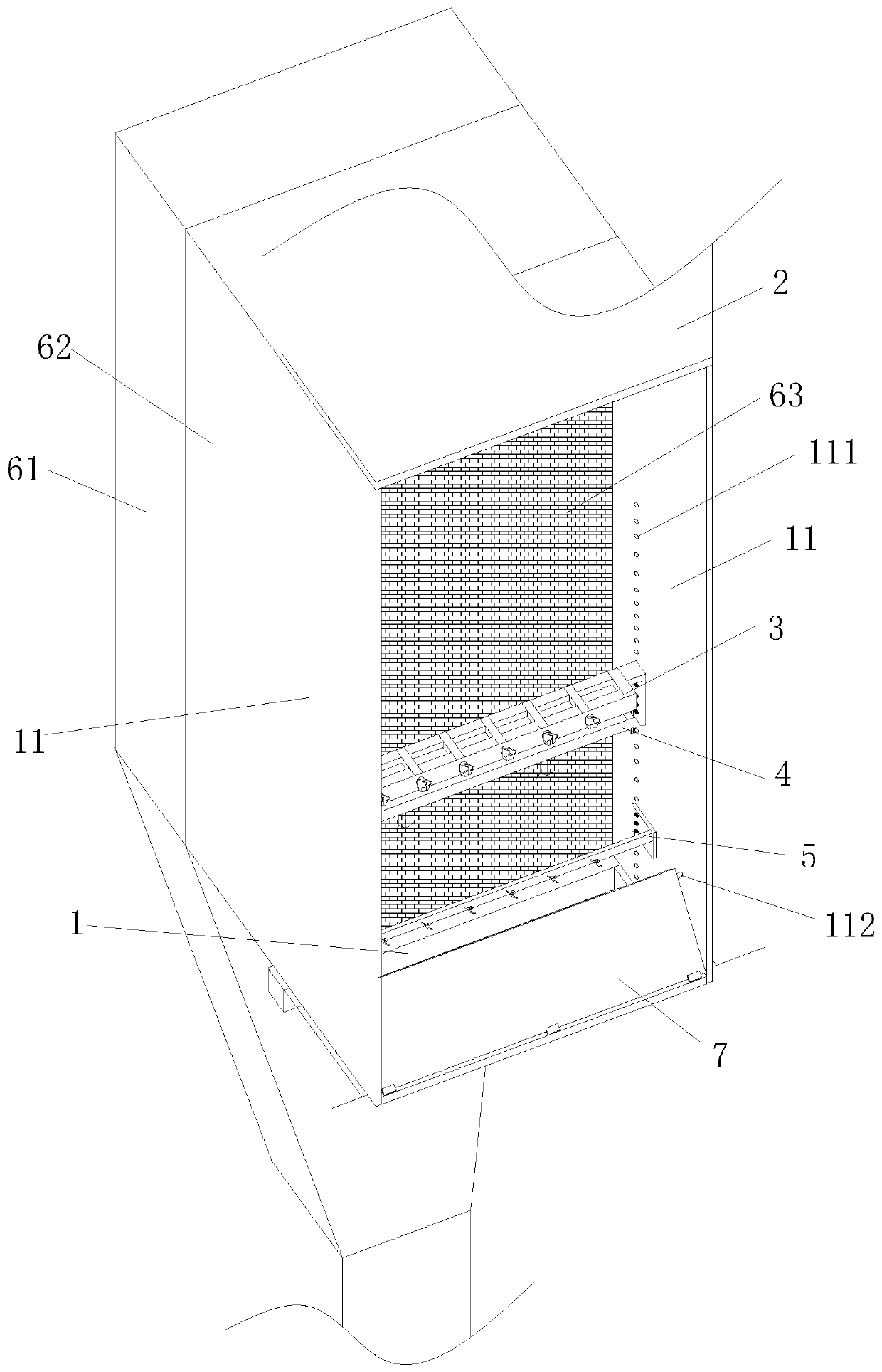

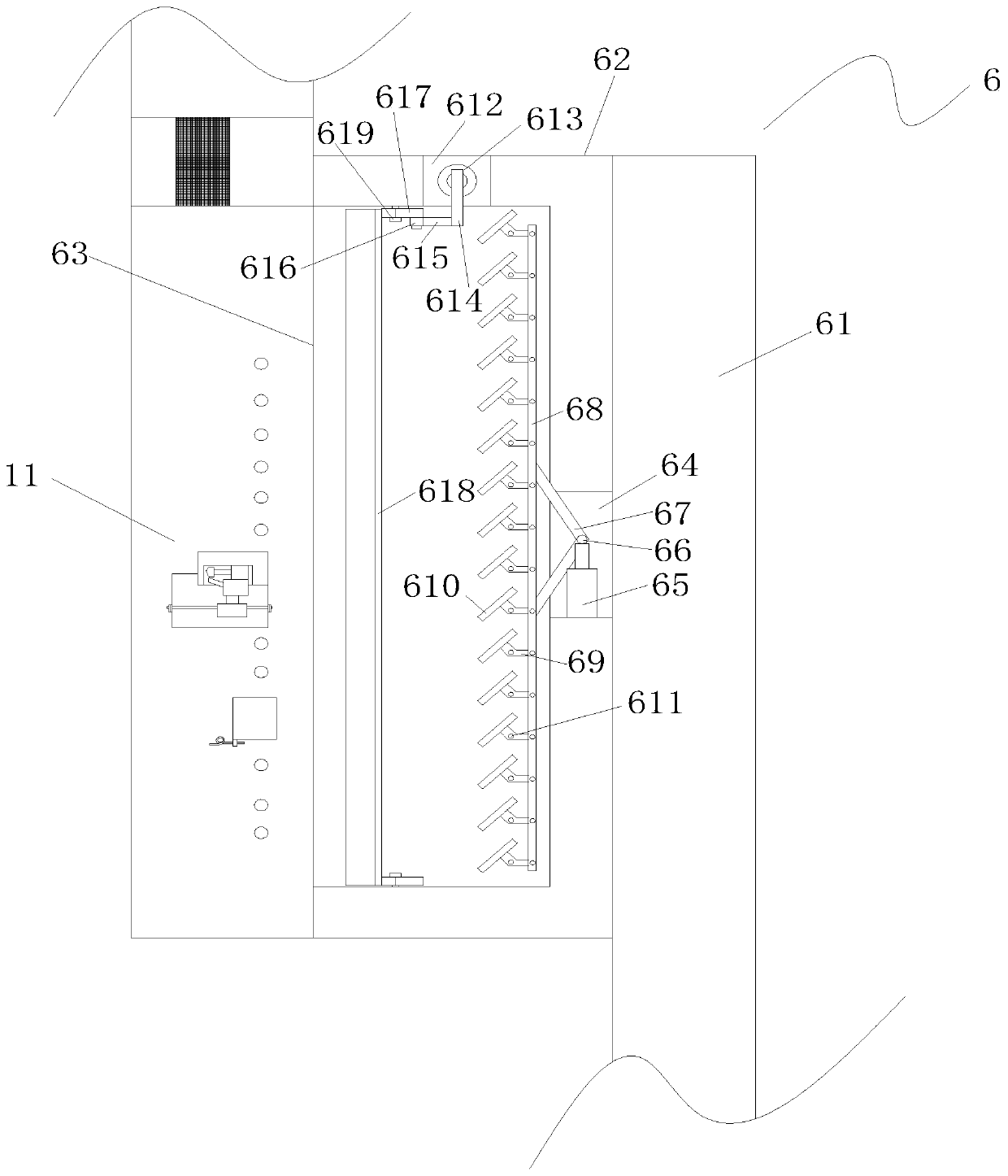

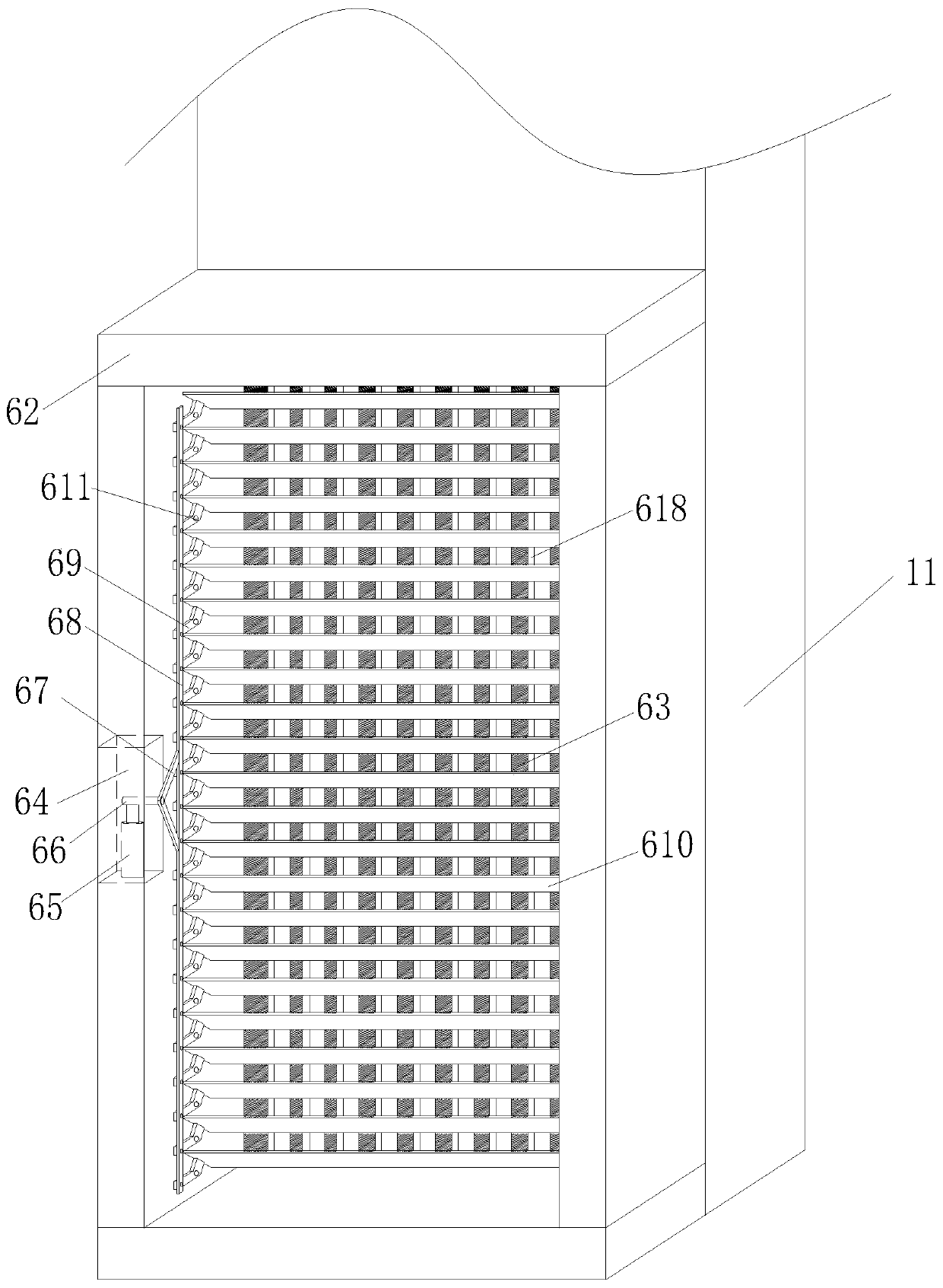

[0022] see Figure 1 to Figure 6As shown, the unmanned automatic production equipment of a kind of imitation wool nylon filament of the present invention, comprises the supporting board 11 that is arranged on the both sides of wellhead 1, two supporting boards 11 tops are provided with spinning side blowing box 2, and described spinning A plurality of special-shaped cross-section spinnerets (not shown) are arranged in the wire side blowing box 2, and a plurality of spinneret holes are opened on the special-shaped cross-section spinneret, and the spinneret holes are rectangular; The hole is rectangular, and the length is 1.2~1.3mm, the width is 0.3~0.4mm, and the fiber flow rate is 12~16m / min; the two support plates 11 are sequentially provided with spinning nozzle support frame 3, Spinning oil recovery part 4 and guide wire assembly 5, the positions of the spinning no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com