Rotary electric conduction device and electroplating device

A technology of conductive device and conductive ring, applied in the direction of current conduction device, electrode, electrolysis process, etc., can solve the problems of wear and the unusable rotating conductive structure, and achieve the purpose of increasing the conductive performance, ensuring the stability of the electrical connection and reducing the degree of wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

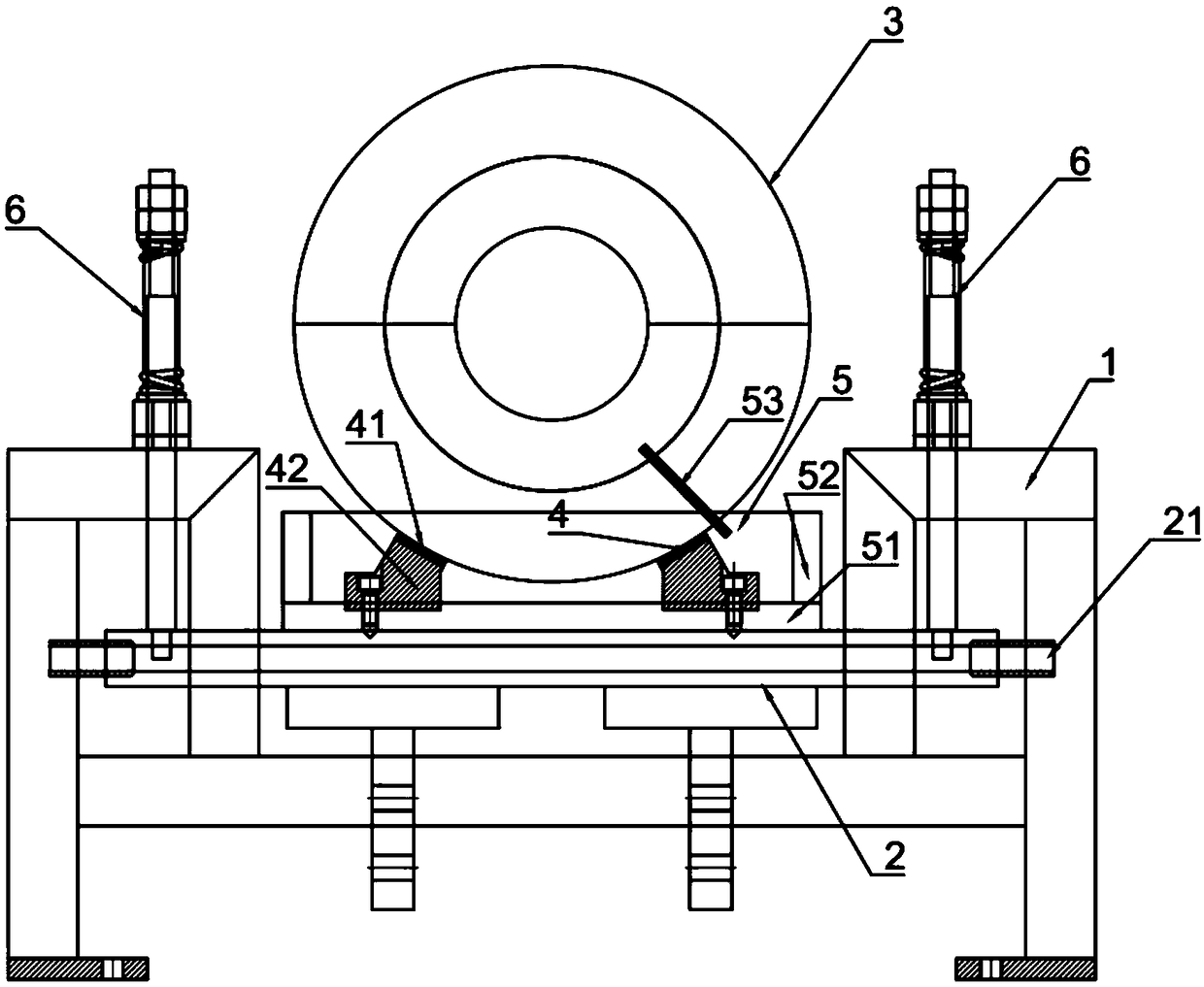

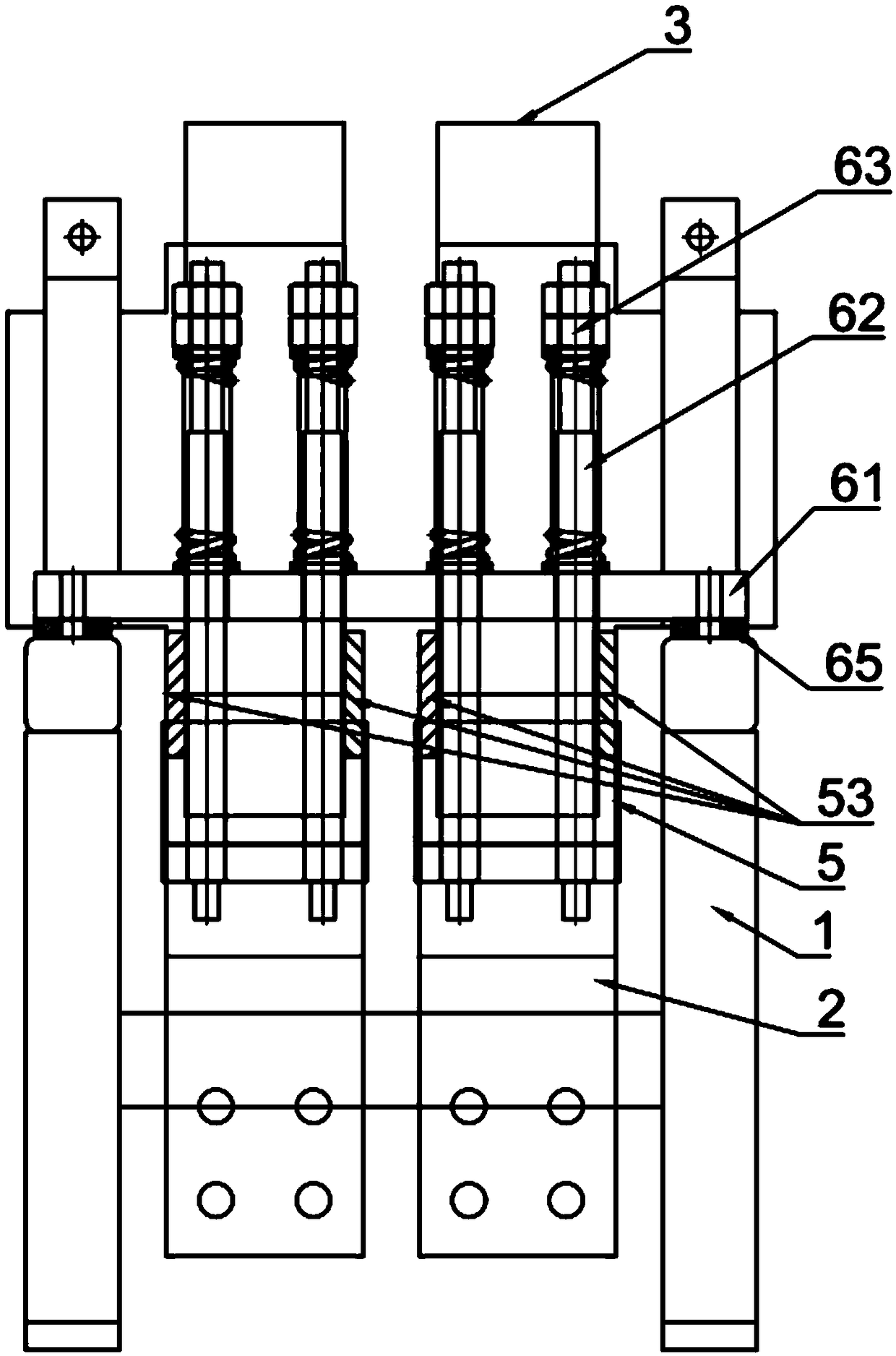

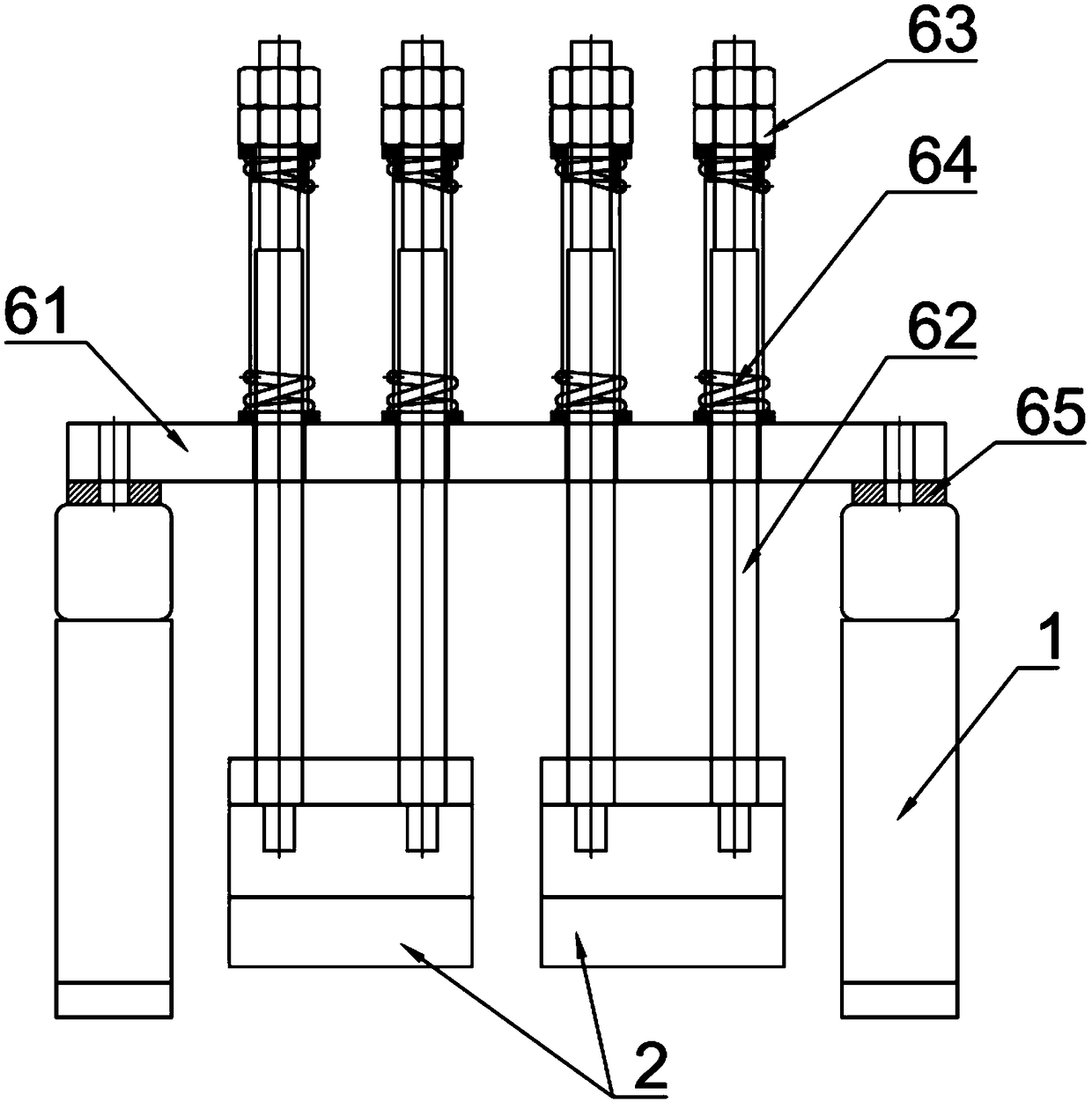

[0050] This embodiment provides a rotating conductive device, the structure of which is as follows figure 1 As shown, it includes a rotating shaft driven by a driving device (not shown in the figure). A conductive ring 3 is sleeved on the rotating shaft, and the conductive ring 3 rotates together with the rotating shaft. The bottom of the conductive ring 3 is provided with a mounting seat 2, and the electrode assembly 4 is installed on the mounting seat 2 and is electrically connected to the surface of the conductive ring 3; the mounting seat 2 is also provided with a conductive oil pool 5, which contains conductive oil, and the electrodes The contact point between the assembly 4 and the conductive ring 3 is immersed in conductive oil for lubricating the contact point between the conductive ring 3 and the electrode assembly 4 . The conductive oil immerses the contact point between the electrode assembly 4 and the conductive ring 3 below its liquid level to reduce the friction...

Embodiment 2

[0069] This embodiment provides an electroplating device, including the rotating conductive device in Embodiment 1, the rotating conductive device is connected between the power supply device and the material to be electroplated, and is used to transmit power to the material to be electroplated. Specifically, the rotating conductive device connects the cathode of the high-power rectifier with the drum wound by the electroplated steel wire rod, and is used for high-efficiency production of electroplated copper-clad steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com