Ultrasonic atomizing pre-charged turbulence condensation device

An ultrasonic, pre-charged technology, applied in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of ineffective multi-field collaborative particle removal, low reliability, complex equipment structure, etc. The effect of promotion prospect, low operating cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing:

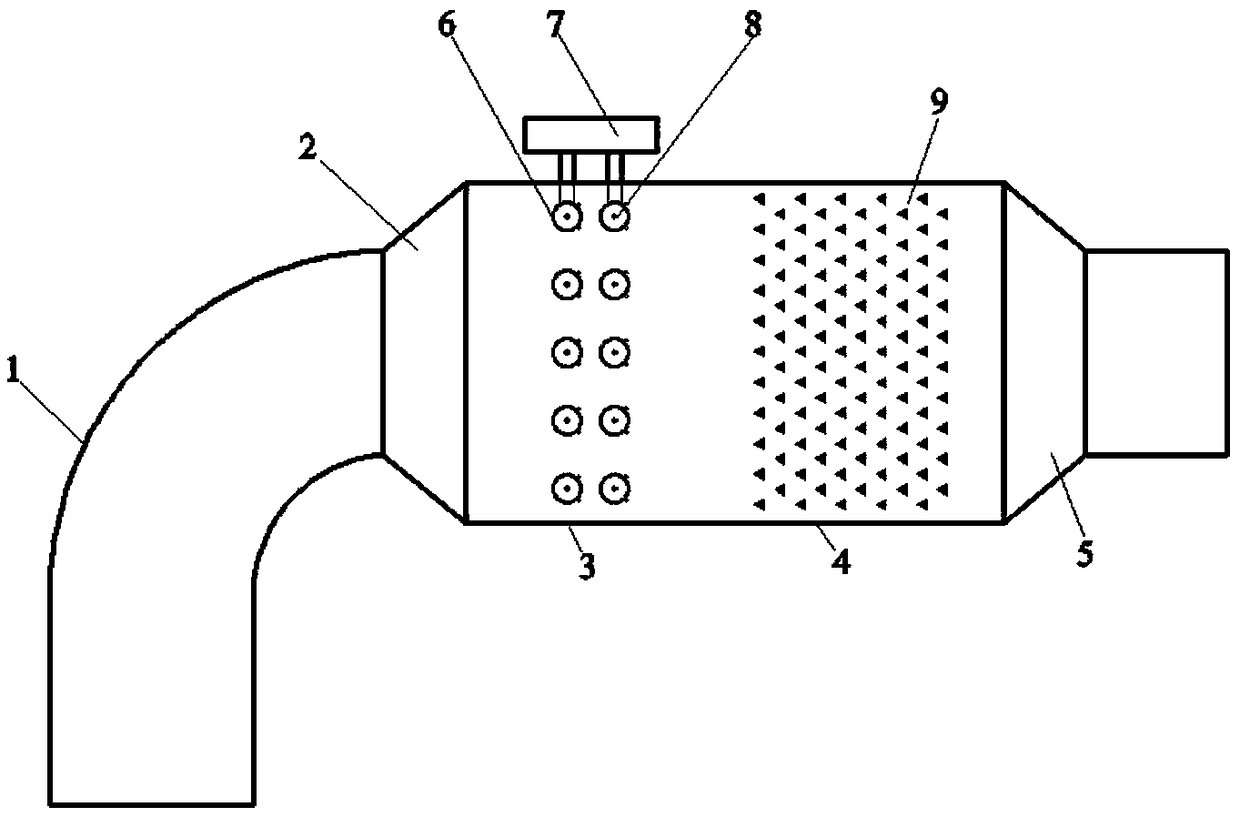

[0030] see Figure 1-Figure 4 , an ultrasonic atomization pre-charged turbulent flow coagulation device, comprising a shell 1, the shell 1 is divided into an inlet gradual expansion section 2, an ultrasonic atomization charging section 3, a turbulent flow condensation section 4 and an outlet tapered section 5; the entrance gradual expansion section 2. Ultrasonic atomization charging section 3, turbulent flow condensation section 4 and outlet tapering section 5 are arranged in sequence from left to right; smoke enters from inlet tapering section 2 and flows out from outlet tapering section 5;

[0031] The ultrasonic atomization charging section 3 includes an atomization charging pipeline 6, an ultrasonic atomization component 7 and a charging component 8, and several atomization charging pipelines 6 are installed on the shell 1 of the ultrasonic atomization charging section 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com