Height adjusting assembly for hedgerow pruning machine

A hedge trimmer and height adjustment technology, applied in the direction of trimming hedge equipment and other directions, can solve the problems of high price and high labor intensity, and achieve the effects of convenient and fast adjustment, firm fixing and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

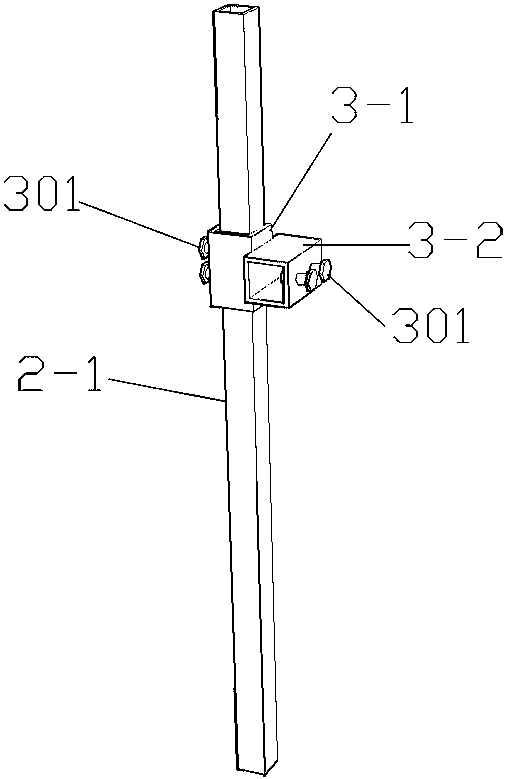

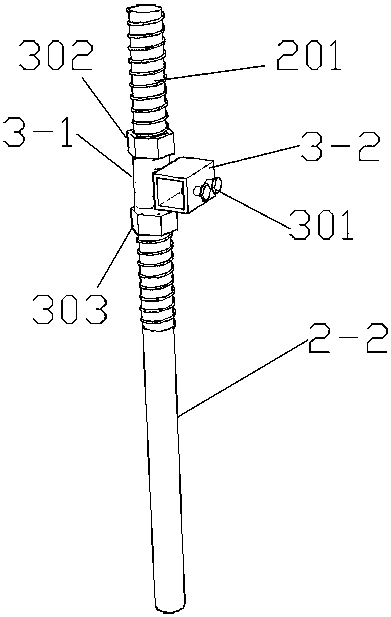

[0019] As shown in the figure, a height adjustment assembly for a hedge trimmer includes two support columns 2 parallel to each other, and a beam arm 1 is fixedly arranged between the two support columns 2, and the beam arm 1 is used for installing hedge trimmers. The trimming mechanism of the machine includes a cutting motor and a cutting piece. The crossbeam arm 1 adopts a square tube structure, and the two support columns 2 are respectively provided with a lifting adjustment mechanism 3. The crossbeam arm 1 is fixed on the two support columns through the lifting adjustment mechanism 3. 2, one of the supporting columns 2 is a square tube supporting column 2-1, and the other supporting column 2 is a circular tube supporting column 2-2, and the outer circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com