Pre-charging method for full-bridge type MMC

A pre-charging, bridge-type technology, applied in current collectors, electric vehicles, electrical components, etc., can solve the problems that full-bridge type MMC cannot be directly applied, and achieve the effect of saving charging time and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

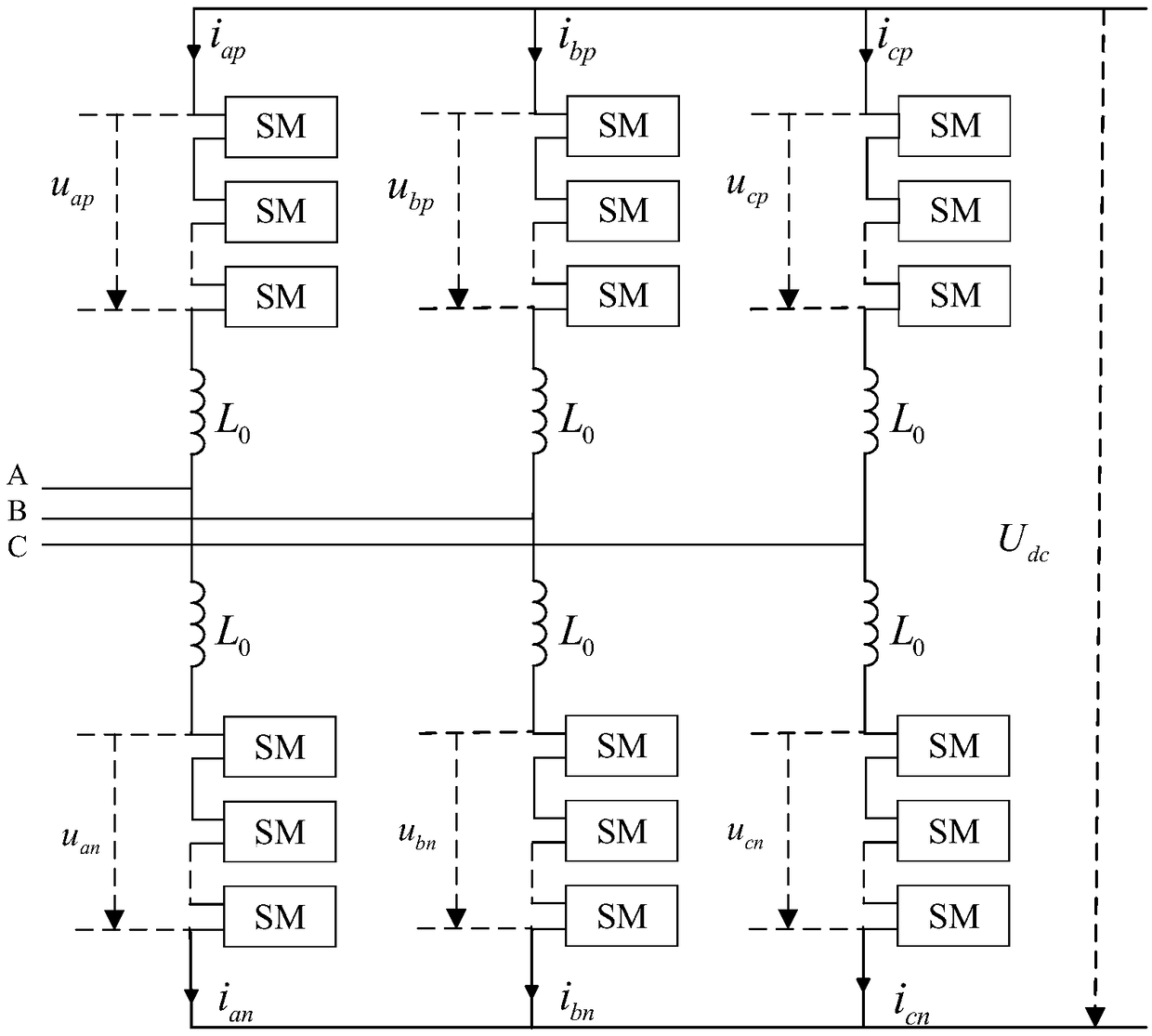

[0034] refer to figure 1 , the full-bridge MMC has 6 bridge arms in total, and each bridge arm is provided with an inductor L 0 and N submodules SM connected in series, the inductance L 0 It is connected in series with the sub-module SM, and the phase unit is composed of upper and lower bridge arms of each phase.

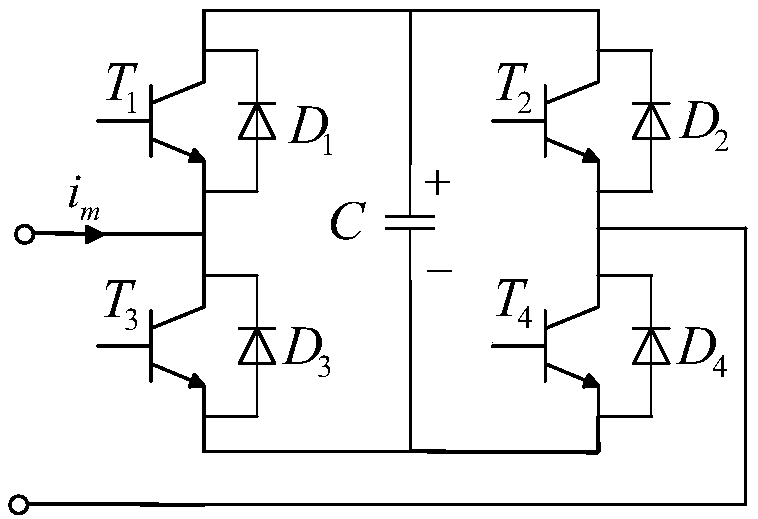

[0035] refer to figure 2 , the sub-module SM is a full-bridge sub-module. The full-bridge sub-module FBSM includes an IGBT full-bridge and a DC energy storage capacitor C. By controlling the on-off of T1, T2, T3, and T4, the sub-module can be put into, There are three states of cutting and blocking, so as to realize the input and cutting of sub-modules.

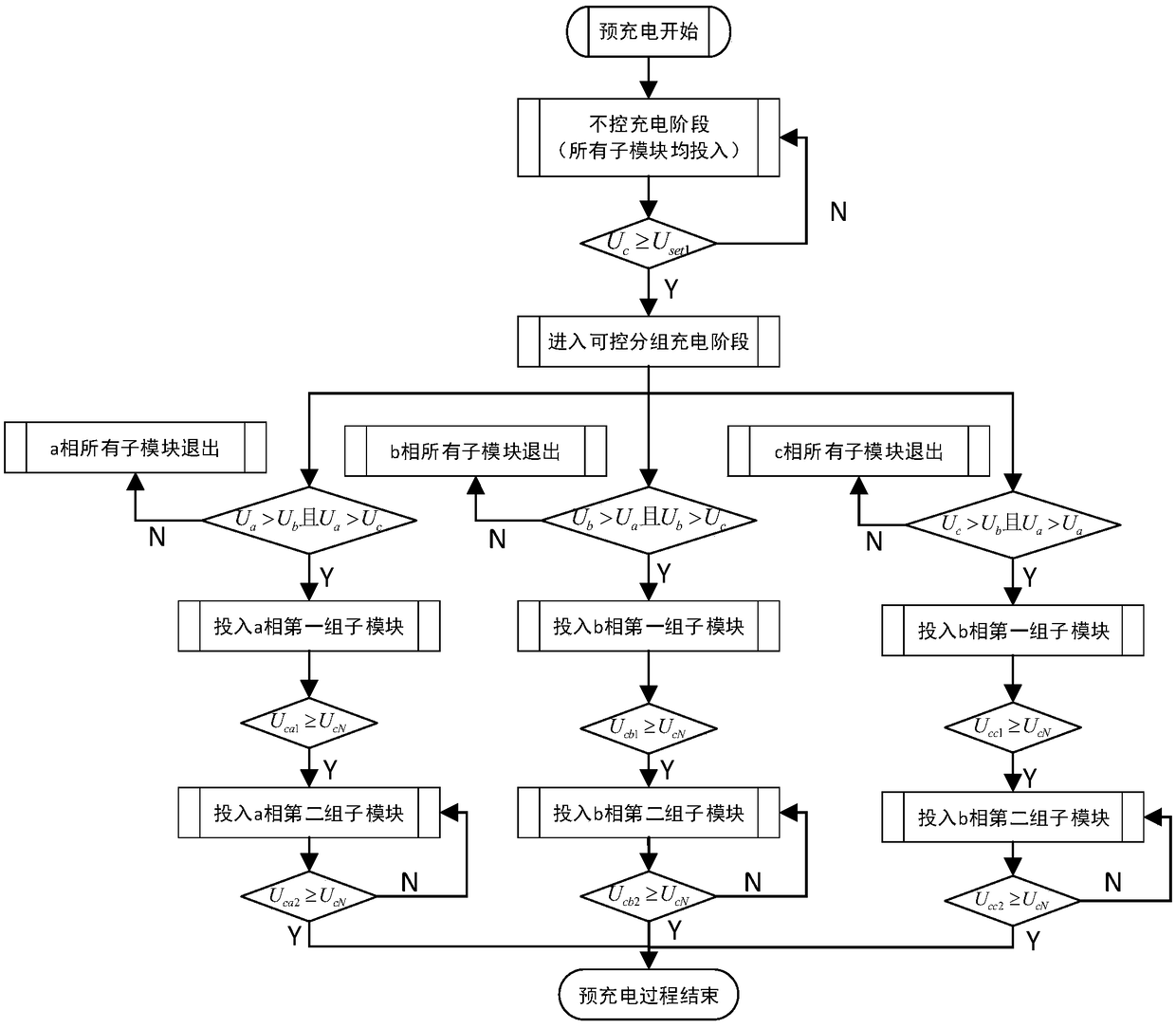

[0036] refer to image 3 , a full-bridge MMC pre-charging method includes an uncontrolled charging stage and a controlled charging stage. In the uncontrolled charging stage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com