Negative pressure suction type steam afterheat recovery device

A steam waste heat and negative pressure suction technology, which is applied to direct contact heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problem of shortening the length of steam outlet pipes, increasing the cost of steam recovery, and increasing steam Pipeline and other issues to achieve the effect of improving energy utilization, increasing profitability, and beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

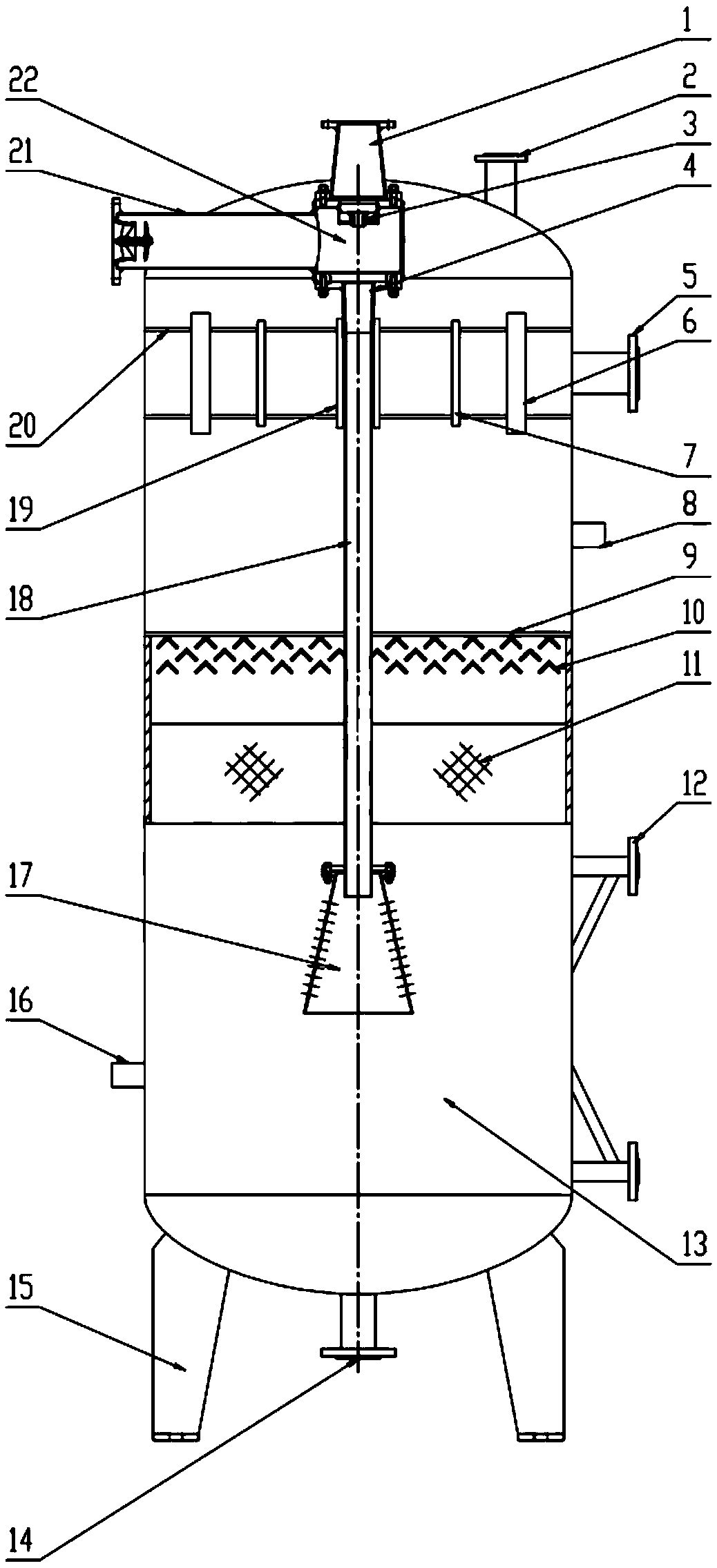

[0033] The condensed water enters from the condensed water connection port 1 and is atomized to the mixing chamber 22 through the nozzle 3. The steam to be recovered enters the mixing chamber 22 from the steam suction pipe 21 and is fully mixed with the atomized condensed water. Enter the flaring pipe 4, enter the anti-suckback device 17 through the water jet pipe 18, the unrecovered steam and water-insoluble gas overflow from the perforation on the surface of the anti-suckback device 17, realize the first steam and heat recovery, and Ready to be recycled;

[0034] The secondary recovered gas overflows from the anti-suckback device 17 and then goes upwards, enters the shower grate group 10 and the gas-liquid mixer 11, fully contacts with the condensed water coming in from the upper condensed water inlet 5, and continues to recover the remaining heat in the gas;

[0035] The film forming plate 20 is a closed box structure, the film forming pipe 6, the overflow exhaust pipe 7 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap