A negative pressure compact spinning device

A negative pressure, agglomeration roller technology, used in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of easy accumulation of flowers in spring gaps, large frictional resistance, and reduced service life, reducing yarn hairiness, The effect of improving single yarn strength and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

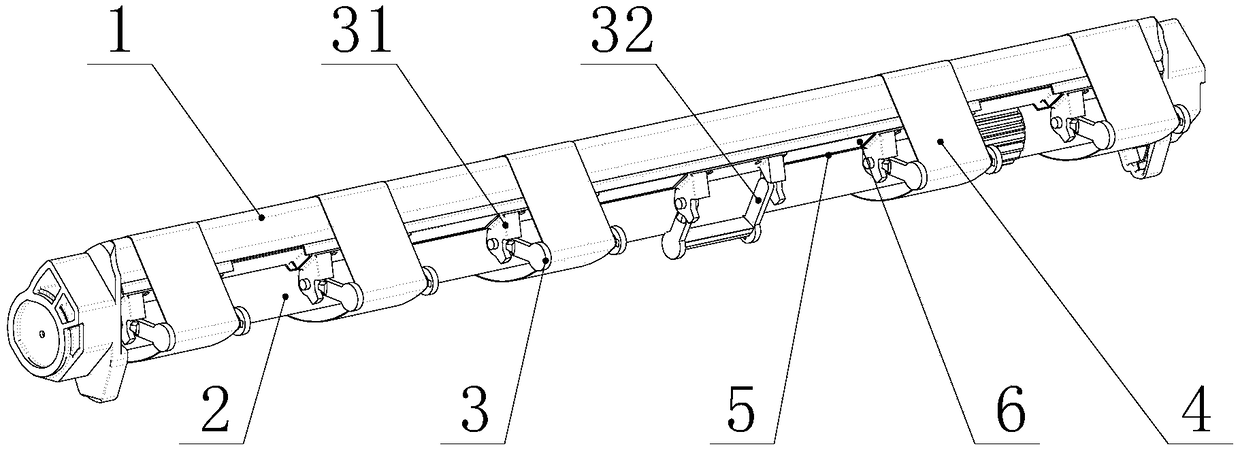

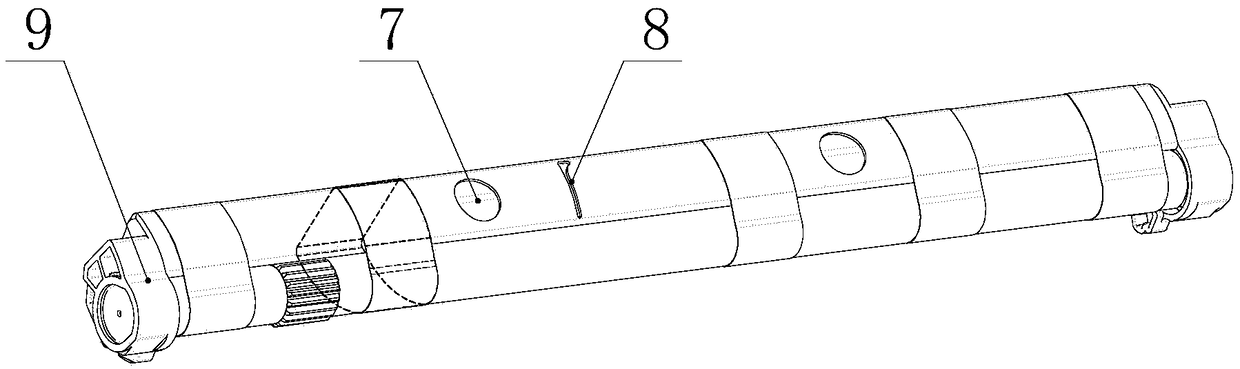

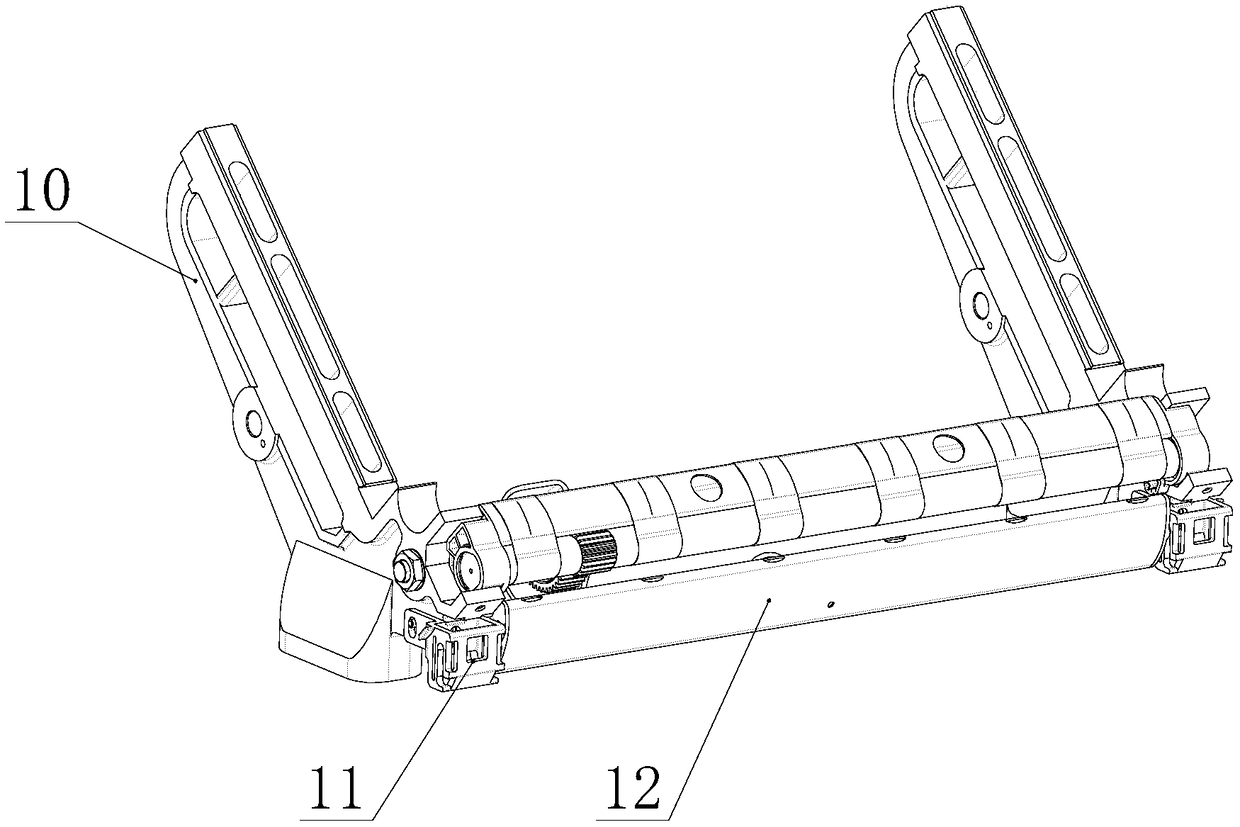

[0064] Such as Figure 1 to Figure 11As shown, a negative pressure compact spinning device in this embodiment includes a special-shaped tube 1 and a gathering roller 2. A plurality of supporting mechanisms 3 are arranged on the lower side of the special-shaped tube 1. The special-shaped tube 1 and the compacting roller A mesh ring 4 is loosely fitted between 2 and the supporting mechanism 3;

[0065] The perimeter of the grid ring 4 is slightly greater than the outer envelope (surrounding) length between the special-shaped pipe 1, the accumulation roller 2 and the support mechanism 3;

[0066] The perimeter of the mesh ring 4 is 1-3mm larger than the outer envelope (surrounding) length between the special-shaped pipe 1, the accumulation roller 2 and the support mechanism 3, and the best size is 2mm greater than its outer envelope length;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com