Automatic gearbox oil and preparation method thereof

An automatic gearbox, selected technology, applied in the field of lubricating oil, can solve the problems of poor cleaning and dispersibility, general friction performance, short service life, etc., and achieve the effects of ensuring oxidation stability, low static friction coefficient, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

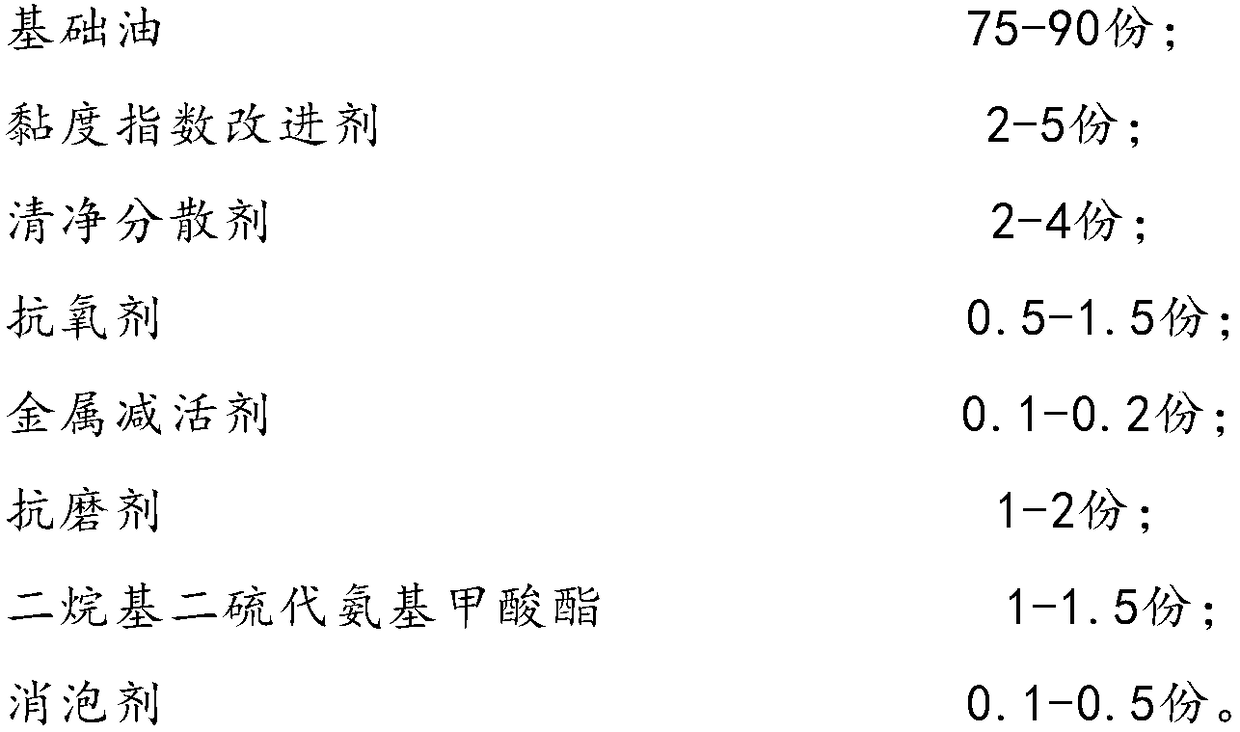

[0028] Prepare raw materials according to the following components and parts by weight thereof:

[0029]

[0030] The base oil has a kinematic viscosity of 8mm at 100°C 2 / s polyα-olefin, the detergent and dispersant is succinimide having an alkenyl group or an alkyl group with a mass average molecular weight of 1,000 to 1,400.

[0031] After the above-mentioned raw materials are prepared, the preparation is carried out according to the following steps:

[0032] S1: Prepared base oil, polymethacrylate, detergent and dispersant, alkylated phenyl-α-naphthylamine, liquid benzotriazole derivatives, chlorinated paraffin, dialkyldithiocarbamic acid Mix the esters in a stirrer, stir at 70°C for 50 minutes, then add the prepared perfluoropolyether grease, stir at 70°C for 15 minutes, and cool to room temperature to obtain mixture A;

[0033] S2: Filter the mixture A cooled to room temperature in S1 under a pressure of 0.2 MPa.

Embodiment 2

[0035] Prepare raw materials according to the following components and parts by weight thereof:

[0036]

[0037] The base oil has a kinematic viscosity of 8mm at 100°C 2 / s polyα-olefin, the detergent and dispersant is succinimide having an alkenyl group or an alkyl group with a mass average molecular weight of 1,000 to 1,400.

[0038] After the above-mentioned raw materials are prepared, the preparation is carried out according to the following steps:

[0039] S1: Prepared base oil, polymethacrylate, detergent and dispersant, alkylated phenyl-α-naphthylamine, liquid benzotriazole derivatives, chlorinated paraffin, dialkyldithiocarbamic acid Mix the esters in a stirrer, stir at 70°C for 50 minutes, then add the prepared perfluoropolyether grease, stir at 70°C for 15 minutes, and cool to room temperature to obtain mixture A;

[0040] S2: Filter the mixture A cooled to room temperature in S1 under a pressure of 0.2 MPa.

Embodiment 3

[0042] Prepare raw materials according to the following components and parts by weight thereof:

[0043]

[0044]

[0045] The base oil has a kinematic viscosity of 8mm at 100°C 2 / s polyα-olefin, the detergent and dispersant is succinimide having an alkenyl group or an alkyl group with a mass average molecular weight of 1,000 to 1,400.

[0046] After the above-mentioned raw materials are prepared, the preparation is carried out according to the following steps:

[0047] S1: Prepared base oil, polymethacrylate, detergent and dispersant, alkylated phenyl-α-naphthylamine, liquid benzotriazole derivatives, chlorinated paraffin, dialkyldithiocarbamic acid Mix the esters in a stirrer, stir at 70°C for 50 minutes, then add the prepared perfluoropolyether grease, stir at 70°C for 15 minutes, and cool to room temperature to obtain mixture A;

[0048] S2: Filter the mixture A cooled to room temperature in S1 under a pressure of 0.2 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com