Forced ventilation horizontal flow biological drying reaction device and method

A technology of forced ventilation and biological drying, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of temperature drop of pile materials and meet manual requirements less, improve the efficiency of bio-drying of piles, and shorten the time of bio-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

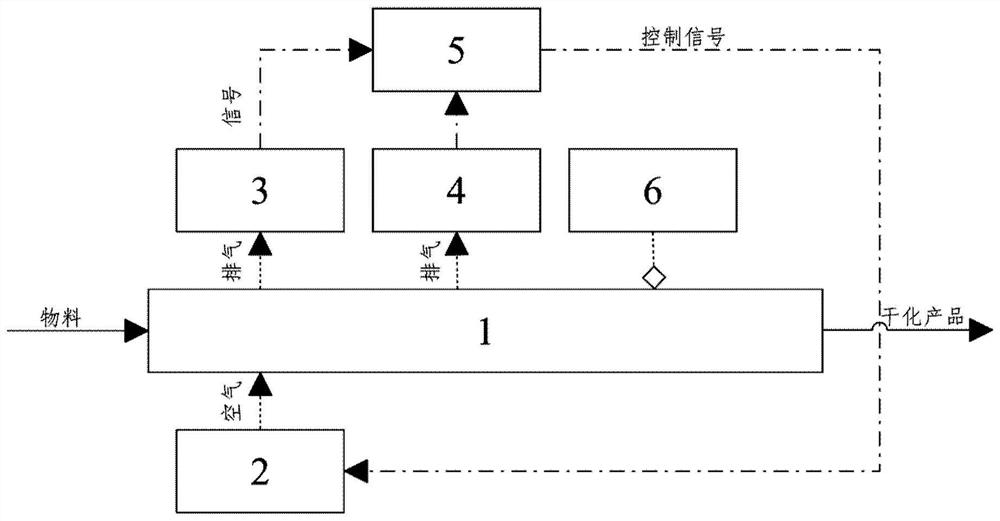

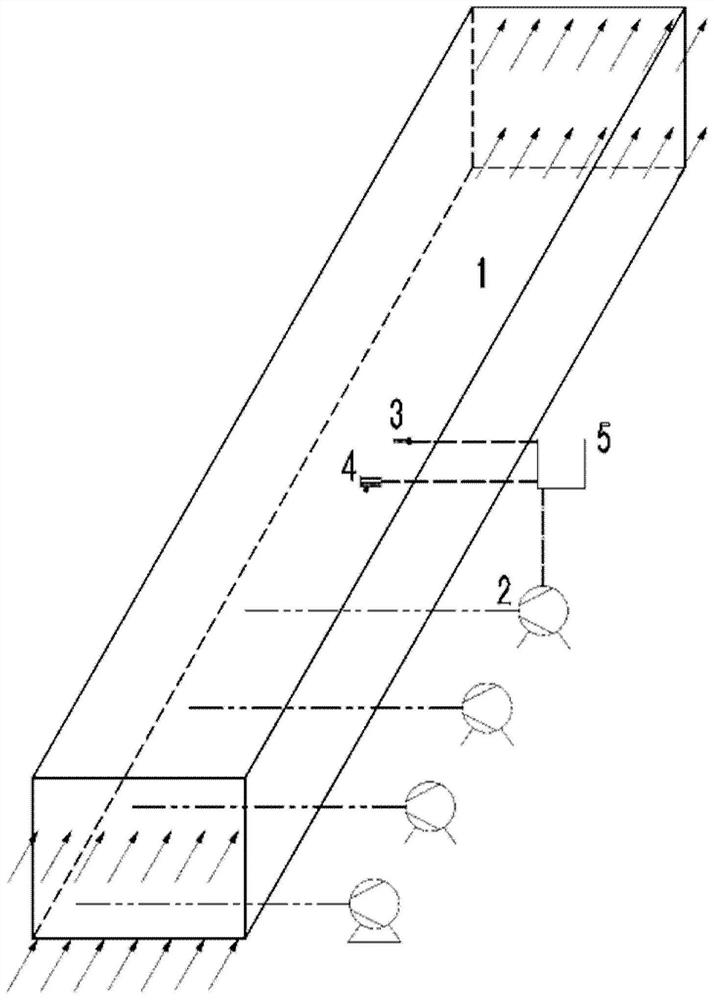

[0079] See figure 2 . The forced ventilation horizontal flow biological drying reaction device is composed of a horizontal flow tank reactor 1, a forced ventilation system 2, a relative humidity sensor 3, an infrared temperature sensor 4, a forced ventilation control system 5 and a mechanical turning device 6 for dehydration Disposal of remaining sludge.

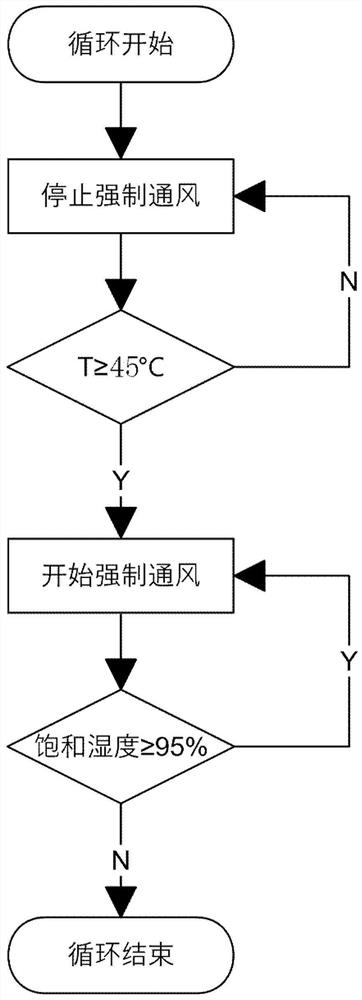

[0080] The dewatered excess sludge with a water content of about 80% from the effluent sewage treatment plant, the back-mixed sludge with a water content of about 40%, and rice bran with a water content of 20-30% are mixed at a ratio of about 1:0.62:0.28 , Adjust the initial moisture content of the material to between 58 and 65%. Then the premixed material is sent into the reactor from the inlet of the horizontal trough bioreactor, and then passes through the six ventilation zones of the horizontal trough reactor 1 in turn; the mechanical turning device 6 simultaneously plays the role of pushing the material and stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com