Testing fiber feeding device of heat exchanger

A technology of feeding device and heat exchanger, which is used in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problem of inability to accelerate dust accumulation test of air conditioner heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

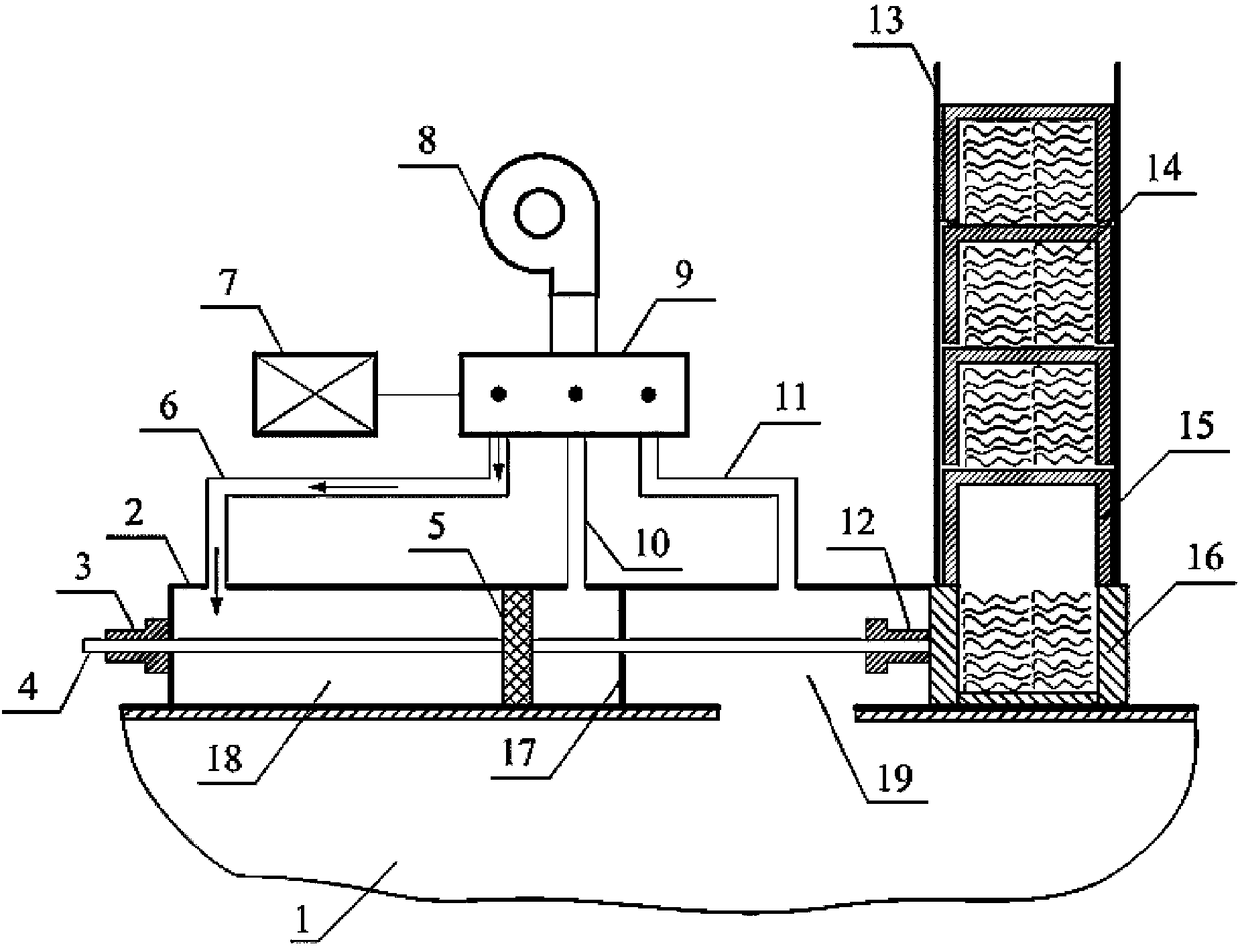

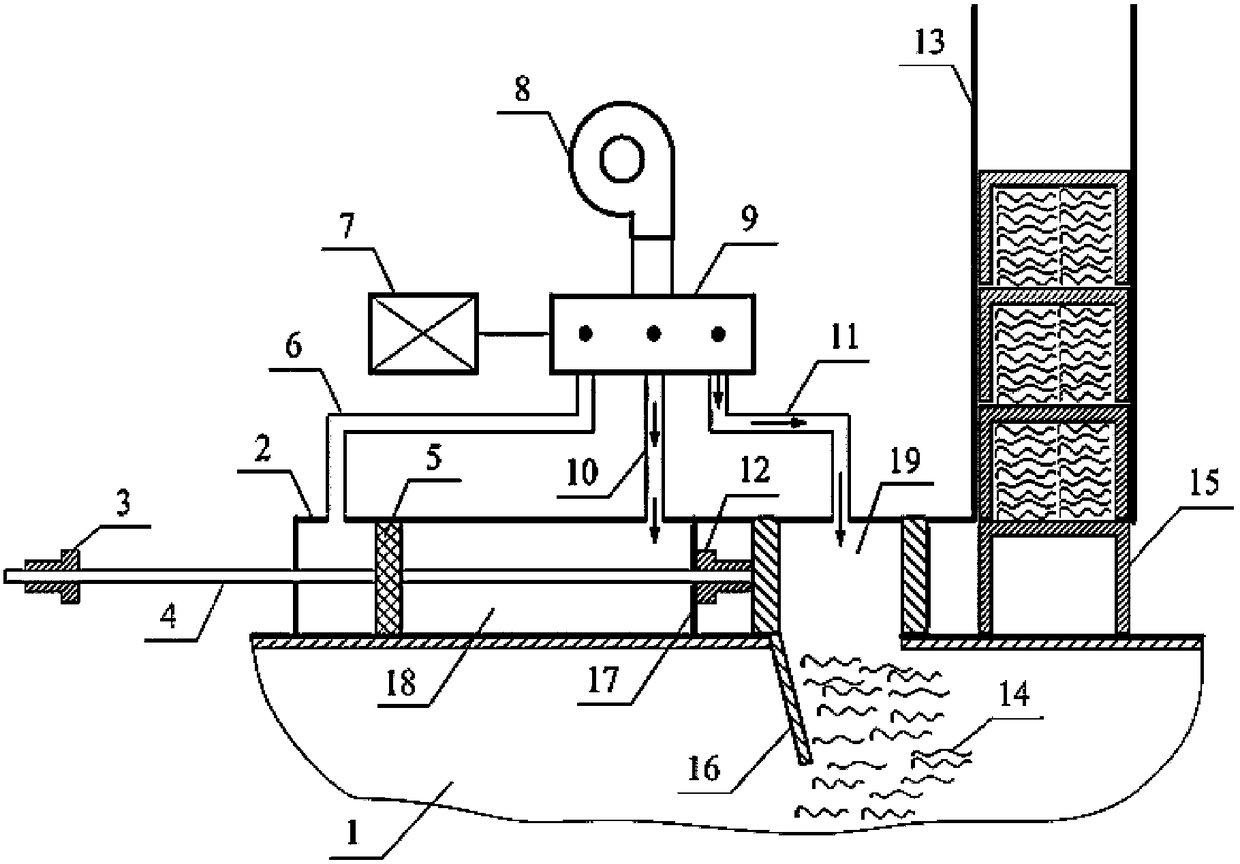

[0017] Such as figure 1 As shown, the present embodiment comprises: a rectangular cylinder 2, a piston rod 4 and a rectangular feed box 16 in cross-section, wherein: a partition 17 is provided in the cylinder 2, a piston 5 is provided on the left side of the partition 17, and the feed box 16 is slidingly arranged on the right side of the dividing plate 17, and the right end of the cylinder 2 is provided with an opening for the feed box 16 to enter and exit the cylinder 2, and the piston rod 4 is arranged on the piston 5 and the dividing plate 17 along the length direction of the cylinder 2, and the right end of the piston rod 4 is connected to the The feeding box 16 is connected to each other, and the cylinder wall on the right side of the dividing plate 17 is provided with a feeding port.

[0018] The cylinder 2 is arranged laterally on the top of the dust chamber 1 , and the cylinder 2 is divided into a drive chamber 18 and a feed chamber 19 by the piston 5 . The feeding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com