Differential displacement sensor and measuring method thereof

A displacement sensor, differential technology, applied in the field of measurement, can solve the problems of processing errors, inability to ensure the consistency of the angle of the triangular wave mirror, and the change of the angle of the incident light, to achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

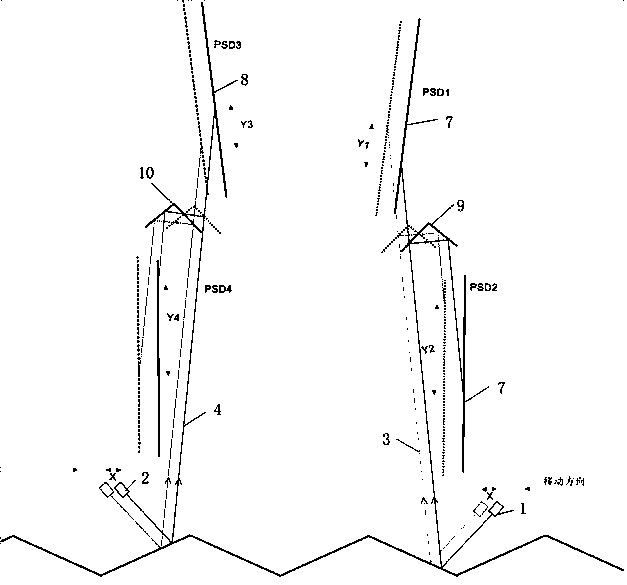

[0036] see figure 2 , a differential displacement sensor is provided in this embodiment, including a laser source-1, a triangular wave reflector 5, a beam splitter group-9, and a photodetector-7, wherein,

[0037] Laser source one 1 is used for emitting laser beam one 3, and shoots to a reflective surface of triangular wave reflector 5; Beam splitter group one 9, comprises beam splitter one and reflector two, and beam splitter one and reflector two are vertically arranged , the laser beam one 3 reflected by the reflective surface of the triangular wave reflector 5 is incident on the beam splitter one, a part of the laser beam one three is incident on one of the photodetectors one after being reflected by the beam splitter one and the mirror two successively, and the other part of the laser beam A 3 is incident on another photodetector 7 after being transmitted by the beam splitter 1; two photodetectors 7 are arranged in parallel, and the incident angles of the laser beam 1 3 ...

Embodiment 2

[0058] can refer to Figure 5 Compared with the differential displacement sensor described in Embodiment 1, the differential displacement sensor provided in this embodiment also includes a laser beam two, which is incident on another reflective surface of the triangular wave reflector 5; and the following components:

[0059] Beam splitter group two 9, comprise beam splitter three and mirror four, and beam splitter three and mirror four are vertically arranged, the laser beam two 4 that described another reflection surface reflection of triangular wave reflector 5 is incident on beam splitter three, a part The laser beam 24 is incident on one of the photodetectors 28 after being reflected by the beam splitter 3 and the reflector 4 successively, and another part of the laser beam 24 is incident on the other photodetector 28 after being transmitted by the beam splitter 3; The positional relationship of the detector 2 8 satisfies: the incident angles of the laser beam 2 4 inciden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com