Phase-shifting and shifting unit combined permanent magnet synchronous linear motor

A technology of synchronous linear motors and permanent magnet synchronous linear motors, which is applied in the field of permanent magnet synchronous linear motors and unit combination permanent magnet synchronous linear motors, and can solve the problems of large thrust fluctuations of linear motors, affecting the performance of linear motors, and the inability to apply precision requirements, etc. , to achieve strong theoretical significance and engineering practical value, suppress significant thrust fluctuations, and eliminate magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

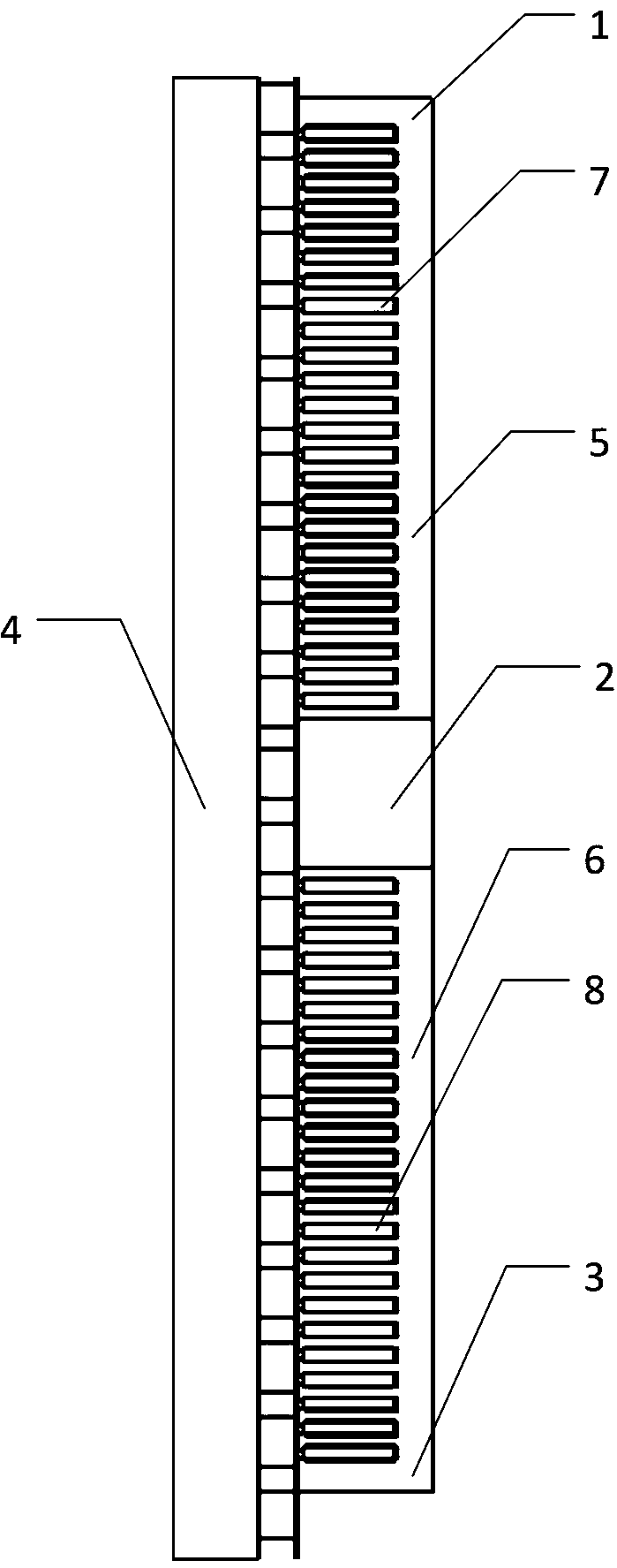

[0020] Such as figure 1 As shown, the motor includes a first unit motor (1), a motor interval (2), a second unit motor (3), a mover (4), a first stator core (5), a second stator core (6 ), the first stator coil (7), the second stator coil (8), and the motor interval (2) are located between the first unit motor (1) and the second unit motor (3).

[0021] The length of the motor interval (2) is 1 / 2t+nT, where t is the tooth pitch of the linear motor, T is the pole pitch of the motor, and n is a positive integer starting from zero. The first unit motor (1) and the second unit motor (3) The structure is exactly the same, the winding arrangement is also the same, the phase difference of the current connected to the first stator coil (7) and the second stator coil (8) is t / T*180°.

[0022] When the linear motor is working, the mover (4) moves linearly in the phase-shifted double-unit motor composed of the first unit motor (1), the motor spacer (2) and the second unit motor (3), Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com