Air tightness detection frame for filter housing

An air tightness detection and filter technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of data deviation of test results, air leakage of filter housing, unreliable positioning and installation, etc. Achieve the effects of simple structure, convenient assembly and installation, and convenient air tightness testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

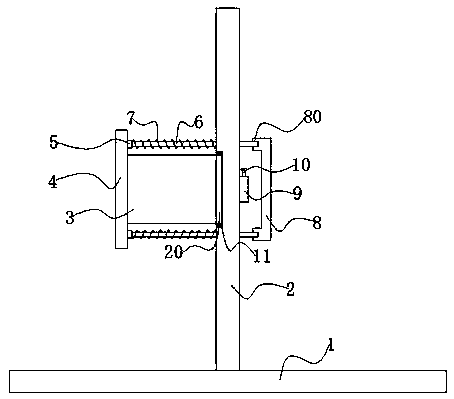

[0013] Such as Figure 1-2 As shown, the invention discloses an air-tightness detection frame for a filter housing, which includes a positioning bottom plate 1, a vertical mounting plate 2, and a vertical mounting plate 2 is vertically welded and connected to the middle position of the positioning bottom plate 1. The left side of the vertical mounting plate 2 is provided with a groove hole 20, and the opened groove hole 20 is installed with the inlet end of the housing part 3 to be tested, and the left end of the housing part 3 The abutting clamping plate 4 is used for clamping and clamping. The right side plate of the abutting clamping plate 4 is fixedly provided with a connecting nut 5, and the connecting nut 5 is located on the upper and lower sides of the housing part 3. The connecting nut 5 is threadedly connected to one end of the guide screw 6. The guide screw 6 is inserted and installed on the vertical mounting plate 2, and the other end of the guide screw 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com