Rotary disc type automatic feeding, sewing and discharging tool

An automatic feeding and turntable technology, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of incomplete positioning, high labor costs, and shifting of cloth fixtures, etc., to reduce labor costs and increase work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

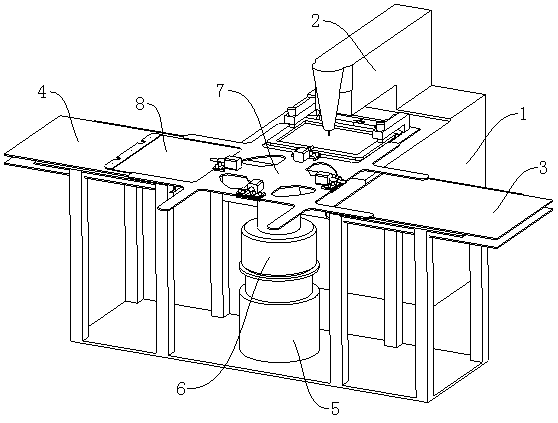

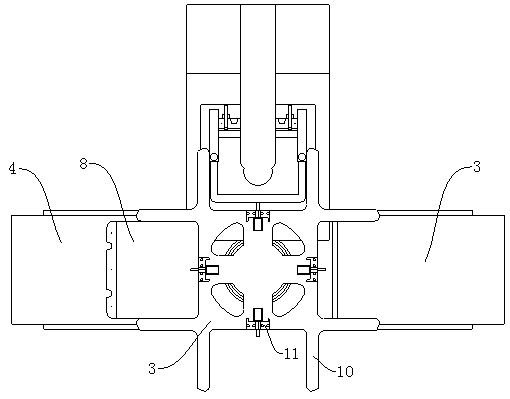

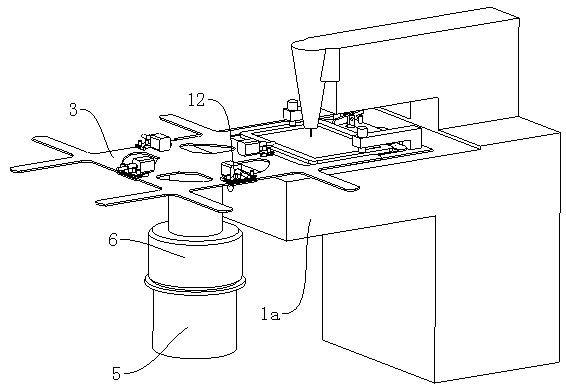

[0026] Reference Figure 1 to Figure 7 A rotary table type automatic feeding, sewing, and unloading tool is shown, including a sewing station, a feeding conveyor belt 3, a discharge conveyor belt 4, a material turnover station and a cloth jig 8. The sewing station includes 2 sewing machines 1 and The sewing machine 2 is fixedly installed on the top of the sewing machine 2 seat 1. The sewing machine 2 seat 1 is provided with a sewing table 1a under the sewing machine 2 and extending forward. The material turnover station is set in front of the sewing table 1a, the feeding conveyor belt 3 and the unloading conveyor belt 4 are arranged on the left and right sides of the material turnover station, and the conveying direction of the feeding conveyor belt 3 and the unloading conveyor belt 4 are the same;

[0027] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com