Universal wine fermentation tank

A wine and fermentation tank technology, applied in the field of multi-functional wine fermentation tanks, can solve the problems of unstable temperature control in the fermentation process, poor convection of grape juice, poor refrigeration effect, etc. Slag cap, the effect of reducing the problem of bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

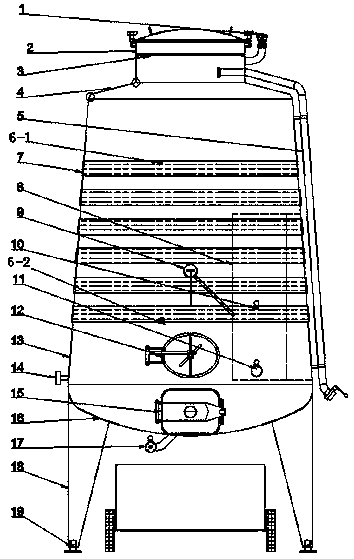

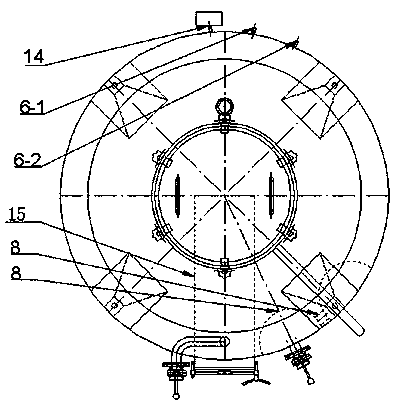

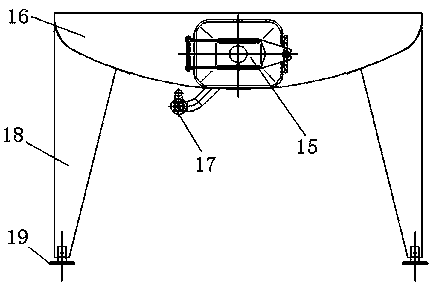

[0032] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, which are used to further describe the structural composition and design principles of the conical convective fermenter of the present invention in detail.

[0033]A general-purpose wine fermentation tank, including a tank body composed of a top-down conical upper head 4, a tank body 13 and a butterfly-shaped lower head 16, the longitudinal section of the tank body 13 is narrow at the top and wide at the bottom Isosceles trapezoidal structure, the angle between the two trapezoidal waists (that is, the inner wall of the tank body) and the lower bottom (that is, the plane of the tank bottom) is 60-80°, and the angle between the two trapezoidal waists (that is, the inner wall of the tank body) and the upper bottom (that is, the plane of the tank top) The angle between them is 100-120°, the height-to-diameter ratio of the tank body is 1.4-2, and the shape of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com