Sawtooth-shaped aircraft weapon cabin noise suppression device

A noise suppression and aircraft technology, applied in the aerospace field, can solve the problems of weakening the impact of the cabin, complexity, and destroying the aerodynamic shape of the aircraft, so as to improve the control effect, reduce the aerodynamic resistance, and achieve the best noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

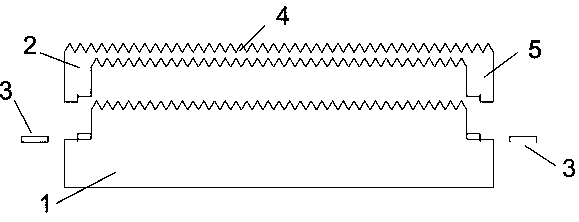

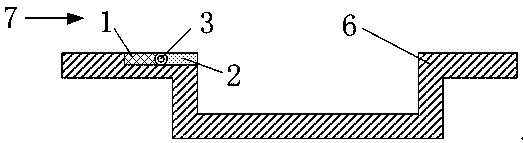

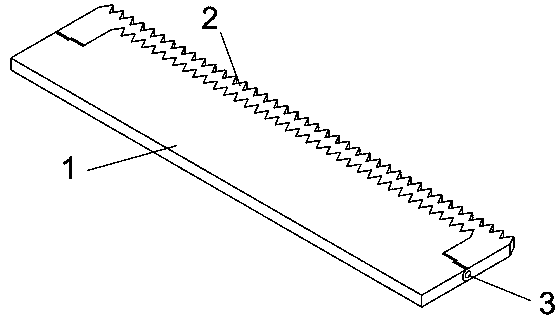

[0030] Such as figure 1 As shown, the spoiler in this example includes a bottom substrate and a spoiler. The spoiler is an inverted concave structure, and the bottom substrate is a convex structure. The overall width of the spoiler shown is w (slightly larger than the downstream cavity The width of ), the height is h (greater than the thickness of the maximum incoming boundary layer), and the thickness is d. The middle beam part of the spoiler has the same width as the downstream cavity. The upper and lower surfaces are both sawtooth structure, the tooth angle is 60°, the tooth height is 2mm, all the saw teeth are closely adjacent, the upper and lower edge of the sawtooth tip distance is about 0.3h, supported on both sides The width of the strip is about 5mm.

[0031] The substrate is a convex structure, the width is the same as the width of the spoiler, both are w, the total height is about 2h, and the thickness is d. The width of the protruding part is the same as that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com