Injection mold

An injection mold and movable mold technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of lowering product grades, large differences in product quality, labor and other problems, so as to facilitate the clamping operation, improve the appearance quality, realize the The effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

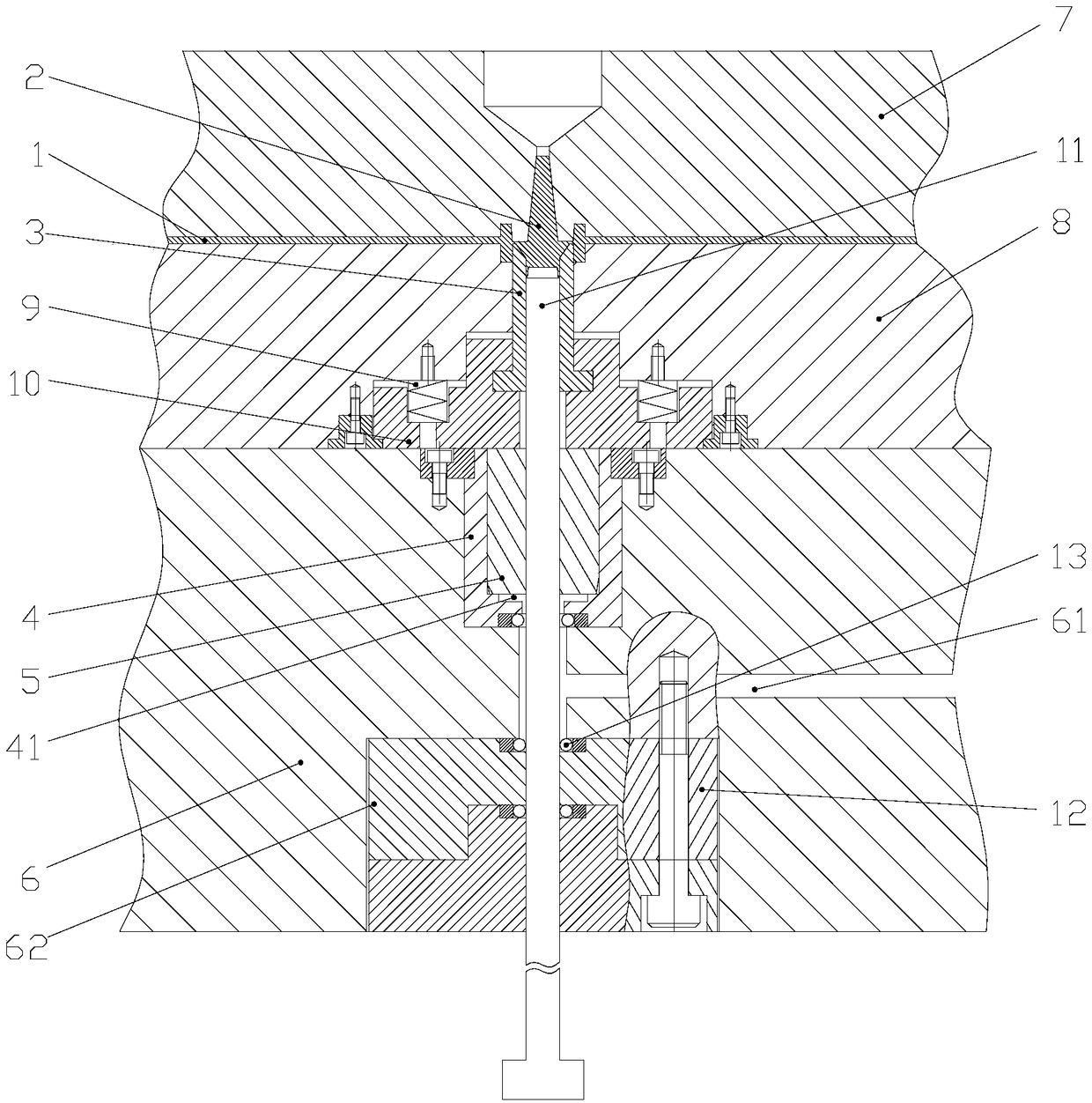

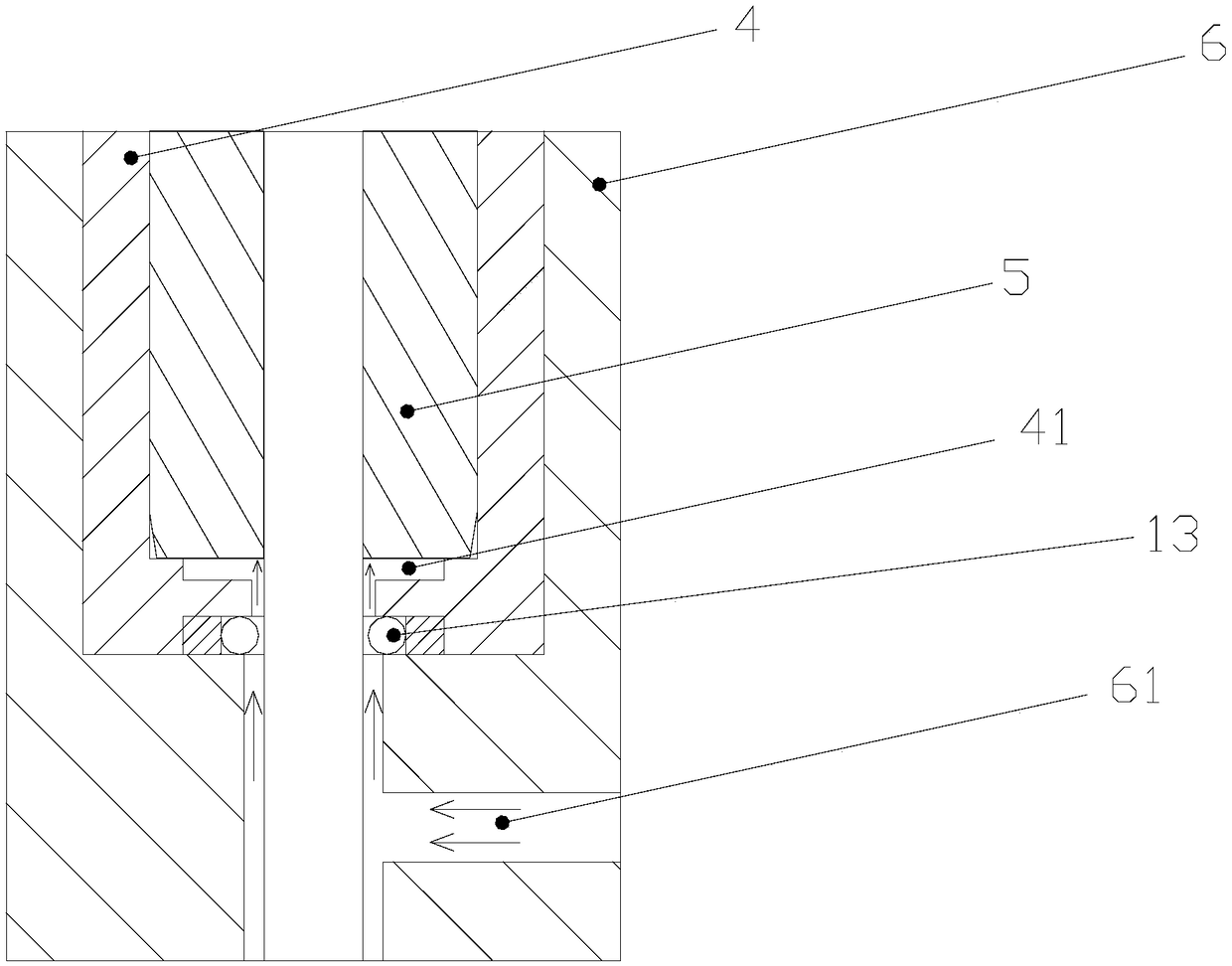

[0032] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

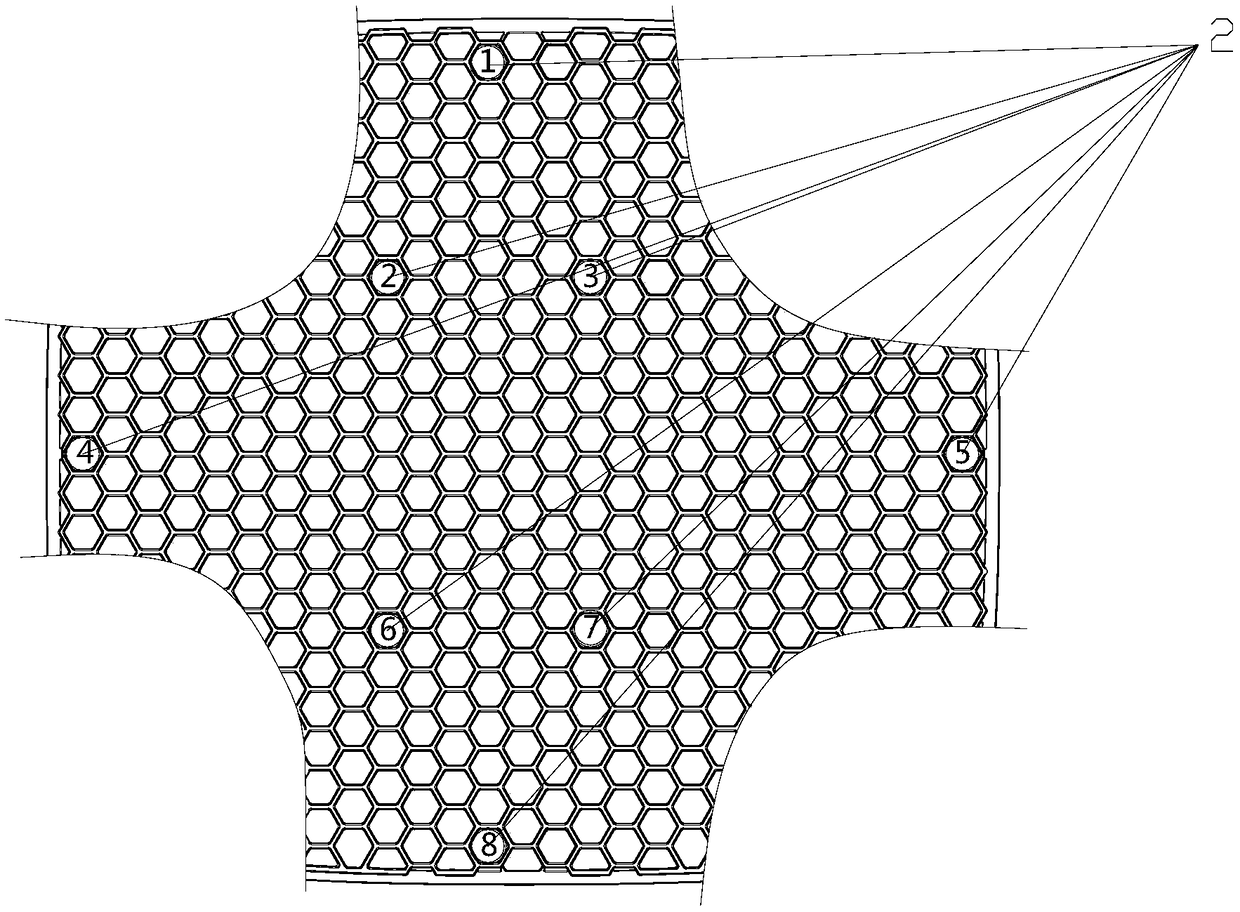

[0033] Such as figure 1 Shown is a schematic diagram of the gate position of an injection molded product, which is a honeycomb design. In order to ensure the appearance quality of the transparent grille, the gate is not allowed to be poured directly on the glue position, which will leave spray lines on the surface of the punched plastic part. This kind of plastic parts basically choose the side gate pouring solution to solve the problem of punching. Problem, and it is not allowed to leave gate marks. The plastic honeycomb transparent grille has an overall size of 269X297X20, and the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com