A processing method for removing chromium and arsenic in kelp

A processing method and technology of kelp, which is applied in the field of food processing, can solve the problems of lack of efficient processing methods for removing chromium and arsenic in kelp, and achieve the effect of bright green appearance, simple process, and fresh and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

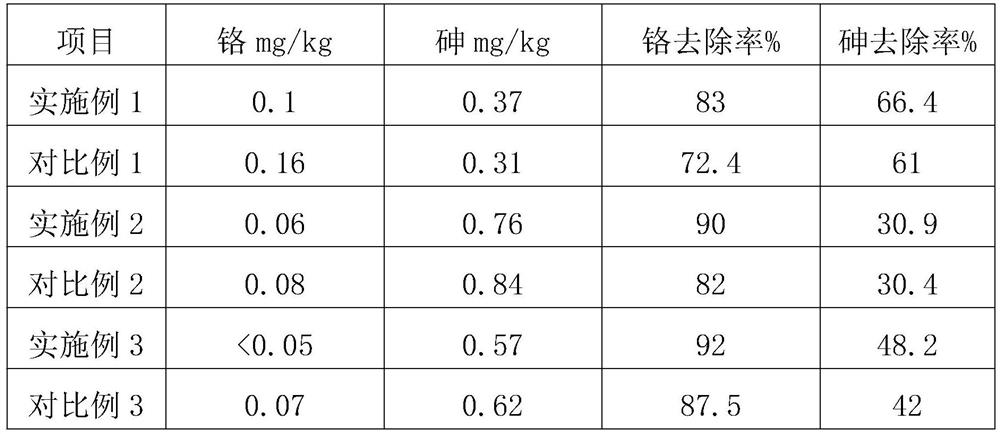

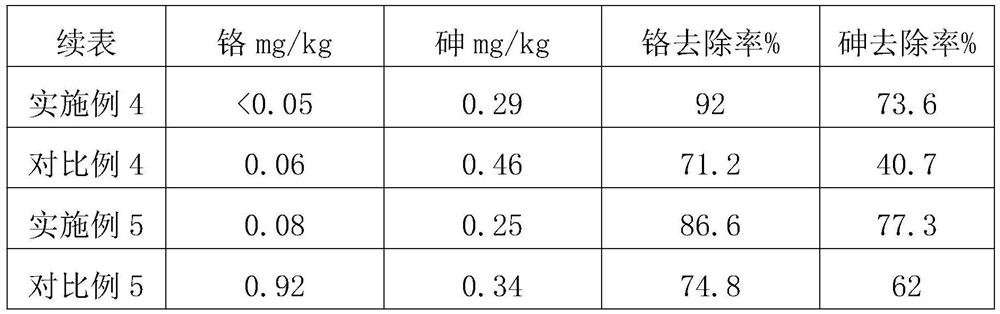

Embodiment 1

[0028] Raw materials: dried kelp products. Follow the steps below: S1. Raw material processing: Soak the cleaned and removed kelp in pure water for 8 hours to make the kelp fully absorb water and soak until the weight of the kelp no longer increases. Take it out and rinse it with clean water; S2. Protect the color : the kelp after S1 treatment is placed in a concentration of 1g / L calcium hydroxide solution for color protection treatment for 5 minutes, and then rinsed in clear water for 3 times to remove the residual calcium hydroxide solution on the surface of kelp; S3, high temperature and high pressure flow Chemical treatment: the kelp washed and soaked in S2 is treated with high-temperature fluidization technology, the temperature is 110°C, and the processing time is 30s; S4, deodorization: the kelp treated in S3 is fumigated in hot steam at 100°C for 2 minutes , to remove the fishy smell of kelp; S5, rinsing and cooling: place the kelp after S4 deodorization treatment in c...

Embodiment 2

[0030]Raw material: fresh kelp. Follow the steps below: S1. Raw material processing: Soak the cleaned and removed kelp in pure water for 4 hours to make the kelp fully absorb water and soak until the weight of the kelp no longer increases. Take it out and rinse it with clean water; S2. Protect the color : After the S1 treatment, the kelp is placed in a calcium hydroxide solution with a concentration of 1g / L for color protection treatment, and then rinsed in clear water for 5 times to remove the residual calcium hydroxide solution on the surface of the kelp; S3, high temperature and high pressure fluidization Treatment: The kelp after S2 cleaning and soaking is treated with high-temperature fluidization technology, the temperature is 90°C, and the processing time is 10s; S4, deodorization: Fumigate the kelp after S3 treatment in 95°C hot steam for 1min, To remove the fishy smell of kelp; S5, rinsing and cooling: place the kelp after S4 deodorization treatment in clean water and...

Embodiment 3

[0032] Raw material: fresh kelp. Follow the steps below: S1. Raw material processing: Soak the cleaned and removed kelp in pure water for 3 hours to make the kelp fully absorb water and soak until the weight of the kelp no longer increases. Take it out and rinse it with clean water; S2. Protect the color : After the S1 treatment, the kelp is placed in a calcium hydroxide solution with a concentration of 2g / L for color protection treatment, and then rinsed in clear water for 5 times to remove the residual calcium hydroxide solution on the surface of the kelp; S3, high temperature and high pressure fluidization Treatment: The kelp washed and soaked in S2 is treated with high-temperature fluidization technology at a temperature of 90°C and the processing time is 10s; S4, deodorization: the kelp treated in S3 is fumigated in hot steam at 98°C for 2 minutes, To remove the fishy smell of kelp; S5, rinsing and cooling: place the kelp after S4 deodorization treatment in clean water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com