Manufacturing method of one-piece molded shoe embryo

A manufacturing method and integrated technology, applied in footwear, textiles, papermaking, knitting, etc., can solve problems such as poor structural strength of knitted shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

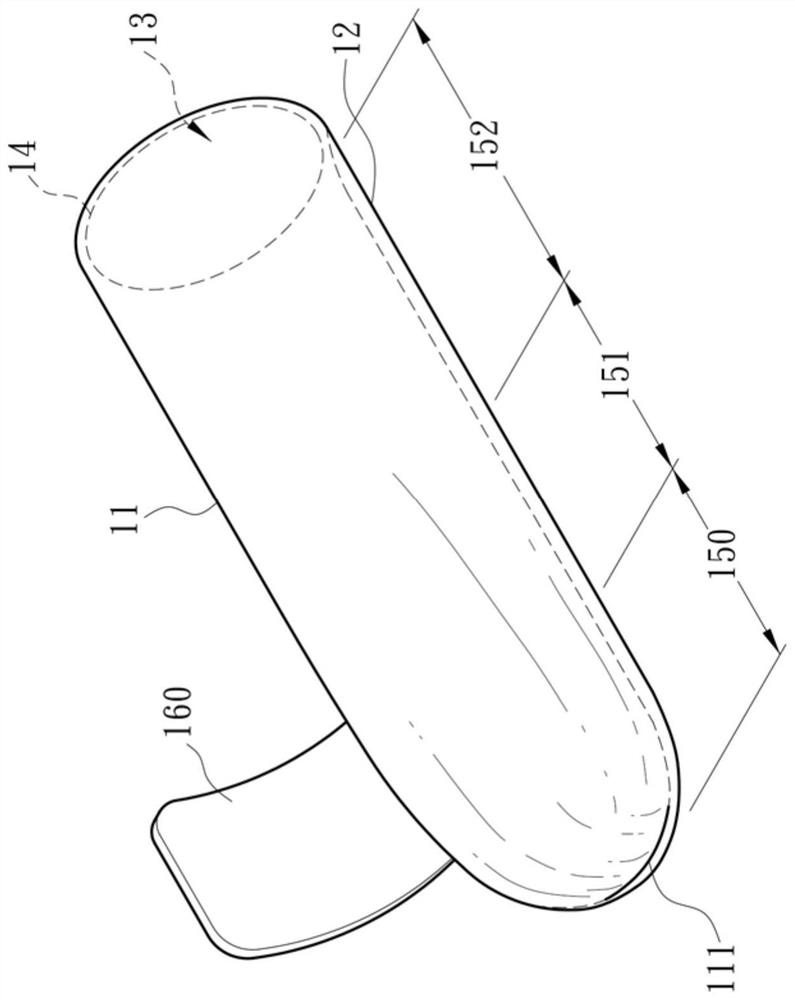

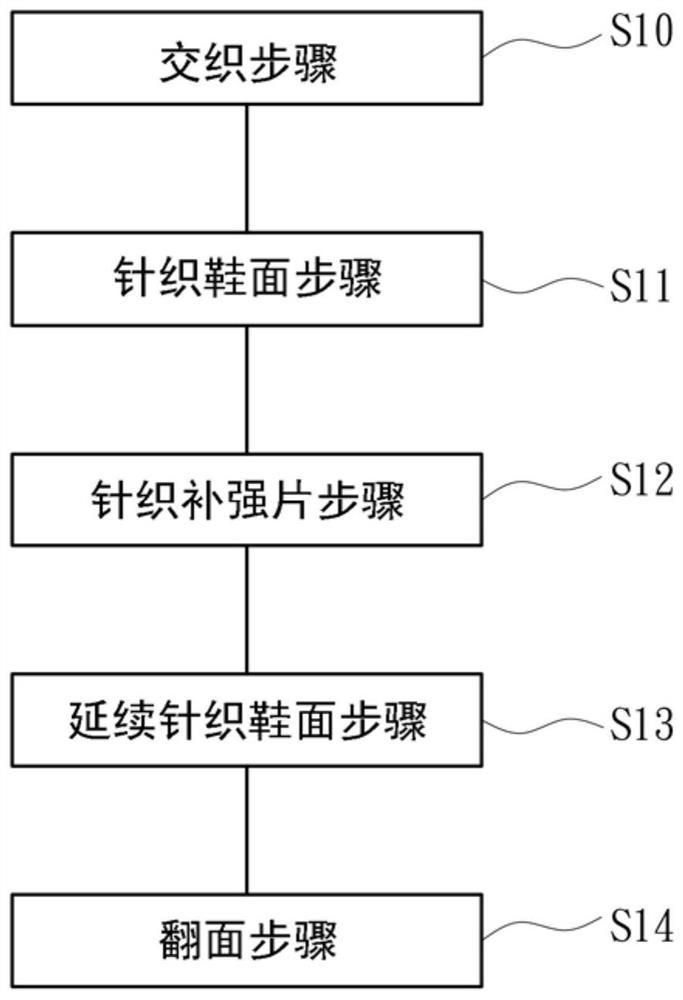

[0091] see figure 1 , the present invention provides a method for manufacturing integrally formed shoe blanks. The knitting-related steps disclosed later in the method of the present invention are all completed by using a flat knitting machine 90, through a front needle bed 901 included in the flat knitting machine 90 It is realized with a rear needle bed 902, and the specific structures of the front needle bed 901 and the rear needle bed 902 are existing technologies in this field, and will not be repeated here. Moreover, during the process of implementing the method of the present invention, the operator of the flat knitting machine 90 can set the front needle bed 901 and the rear needle bed 902 according to the method of the present invention. Furthermore, a yarn feeding mechanism 903 of the flat knitting machine 90 moves along a transverse rail 904, and the yarn feeding mechanism 903 moves from an initial position toward an end position on the transverse rail 904, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com