An online elevator ride quality inspection system and method

An elevator operation and elevator technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of not being widely used in a large area, affecting the detection efficiency, and uneven staff, so as to achieve efficient monitoring, ensure accuracy, and reliable quantitative indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

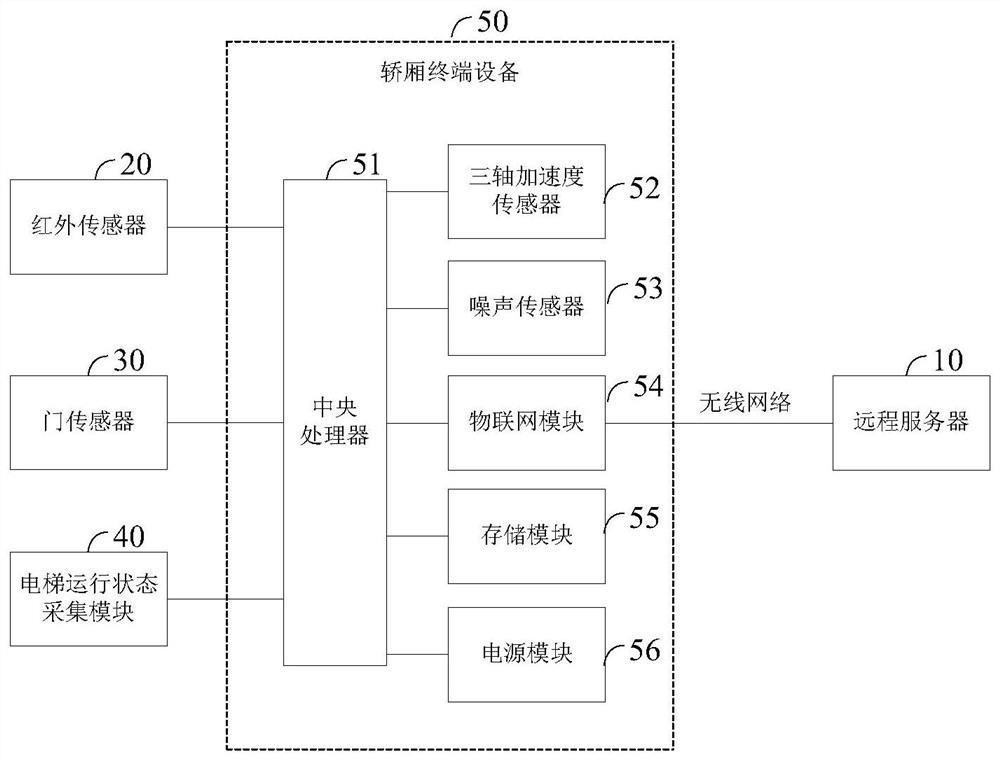

[0057] Such as figure 1 As shown, this embodiment discloses an online elevator ride quality detection system, including: a remote service terminal 10, an infrared sensor 20 installed in the elevator car, a door sensor 30 installed at the position of the door machine of the elevator car, and The elevator running state collection module 40 and the car terminal equipment 50 installed on the top of the elevator car, the elevator running state collection module 40 and the car terminal equipment 50 all run with the elevator, the infrared sensor 20, the door sensor 30 and the elevator running state collection module The output ends of 40 are connected with the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com