Shaping device for manufacturing permeable stone

A molding device and permeable stone technology, applied in manufacturing tools, ceramic molding machines, molding conveyors, etc., can solve the problems of low production efficiency, manual shaking, time-consuming and labor-intensive, etc., so as to improve work efficiency and effect and shorten consumption. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

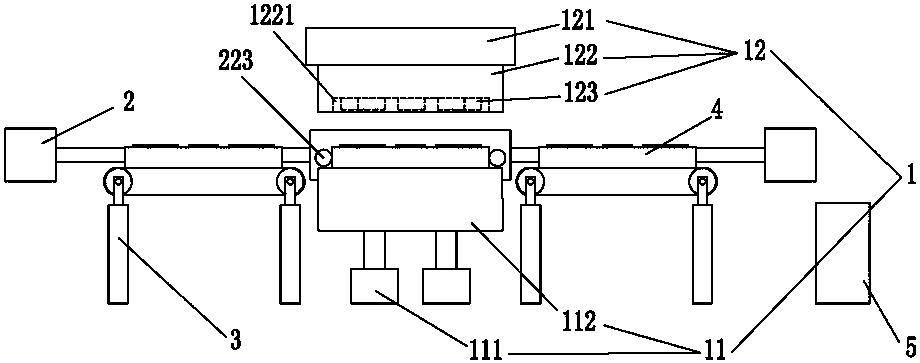

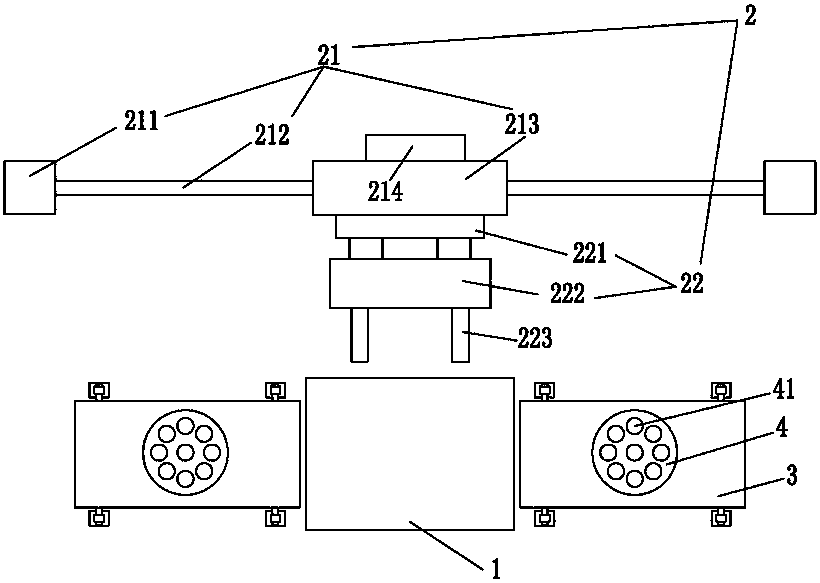

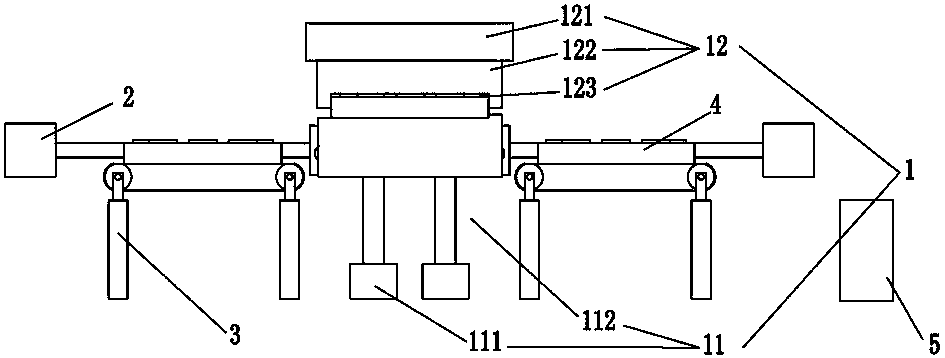

[0021] Such as Figure 1-4 As shown, a molding device for manufacturing permeable stones includes a mold plate 4 filled with raw materials, a molding device 1 for pressing and molding the raw materials in the mold plate 4, and pushes the mold plate 4 into and pushes out the molding The propulsion device 2 of the device 1 also includes a conveyor belt 3 for conveying the mold plate 4, and a PLC controller 5. Two groups of the conveyor belts 3 are arranged on both sides of the molding device 1, and the propulsion device 2 is installed behind the molding device 1. The mold plate 4 is arranged on the conveyor belt 3, the PLC controller 5 is arranged on the right side of the molding device 1, the mold plate 4 is provided with a mold 41, and a plurality of molds 41 are evenly distributed on the mold plate 4. The molding device 1 includes a lifting mechanism 11 and an upper pressing mechanism 12, and the upper pressing mechanism 12 is installed above the lifting mechanism 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com