Parameter mapping-based measurement planning method for complex curved surface

A complex surface and surface technology, applied in the field of complex surface measurement planning based on parameter mapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

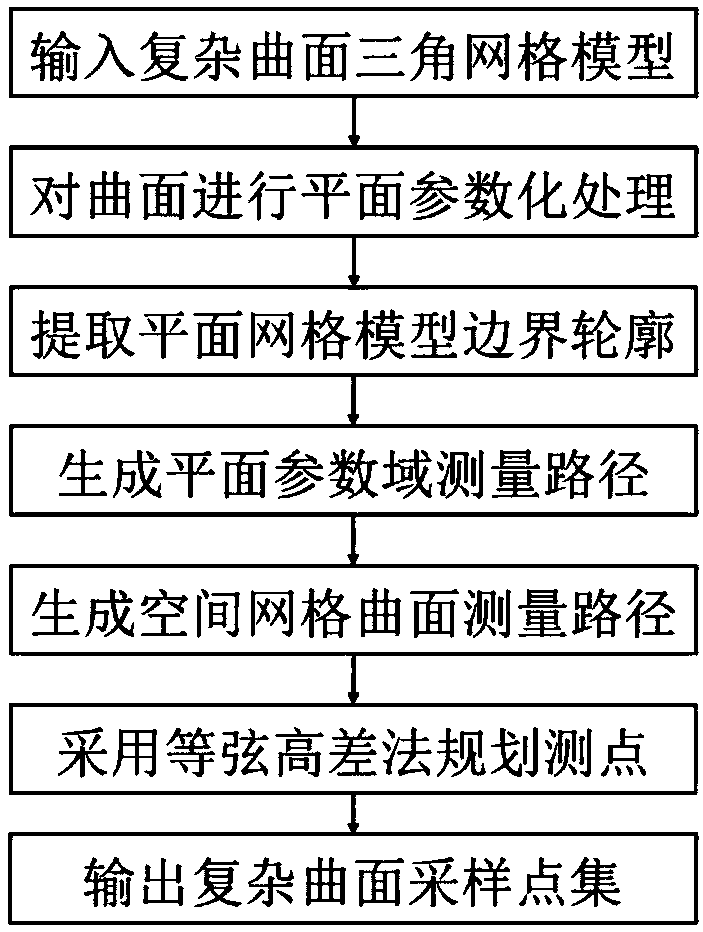

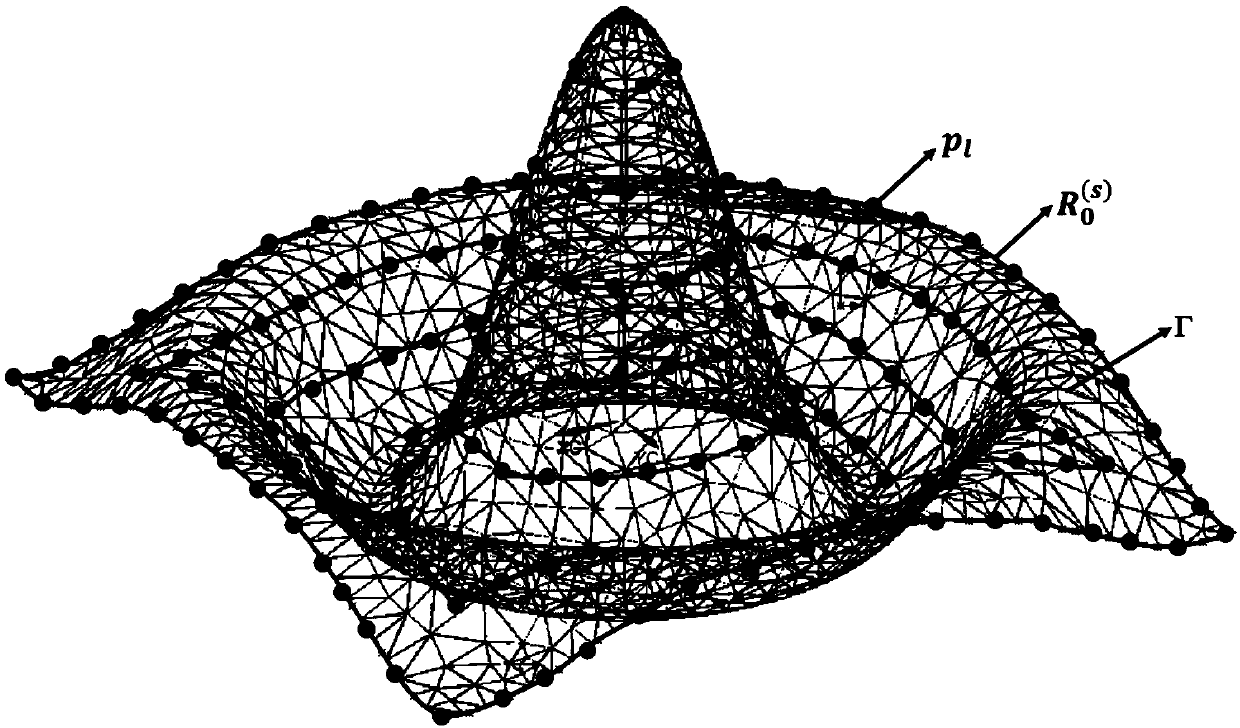

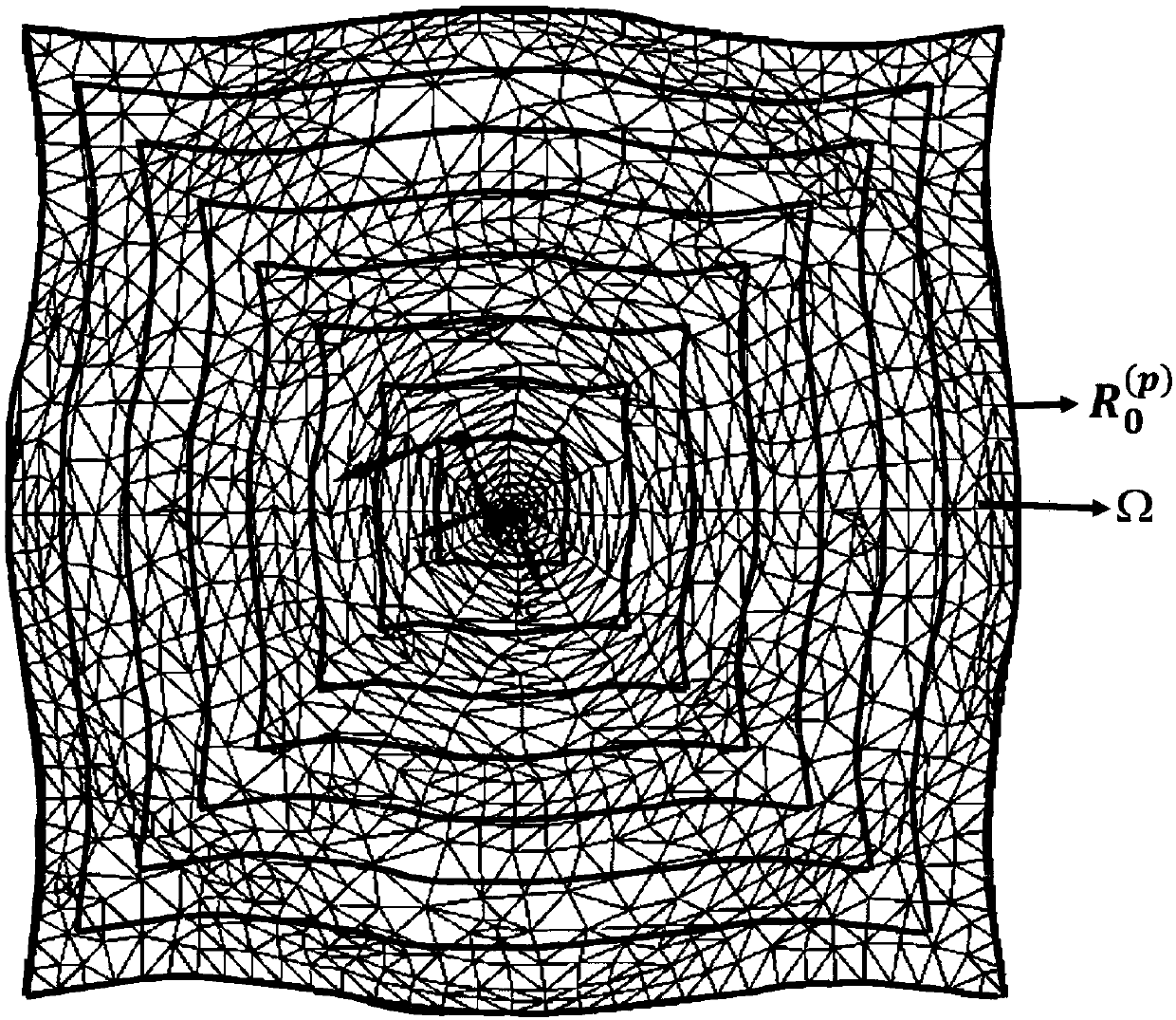

[0040] The triangular mesh surface Γ used in this embodiment is a Mexican straw hat surface model, with a total of 1821 nodes and 3512 triangular elements. The size of the smallest bounding box of the mesh model is 160mm×160mm×80mm, the offset distance Δ is 5mm, and the chord height The tolerance is 2mm. First, the grid parameterization method is used to establish the corresponding relationship between the triangular mesh surface and the plane parameter domain, and then the measurement trajectory planning and measurement point distribution are carried out in the plane parameter domain. The basic flow chart is shown in the attached figure 1 . The specific steps of the method are as follows:

[0041] The first step is to parametrize the triangular mesh surface Γ

[0042] The triangular mesh surface Γ is parametrized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com