Heat pump circulating system with combined defrosting function and operation method

A circulating system and heat pump technology, applied in lighting and heating equipment, damage protection, refrigeration components, etc., can solve the problems of increasing the capacity of the vapor-liquid separator and reducing the comfort, and achieve the goal of speeding up the defrosting process and shortening the defrosting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

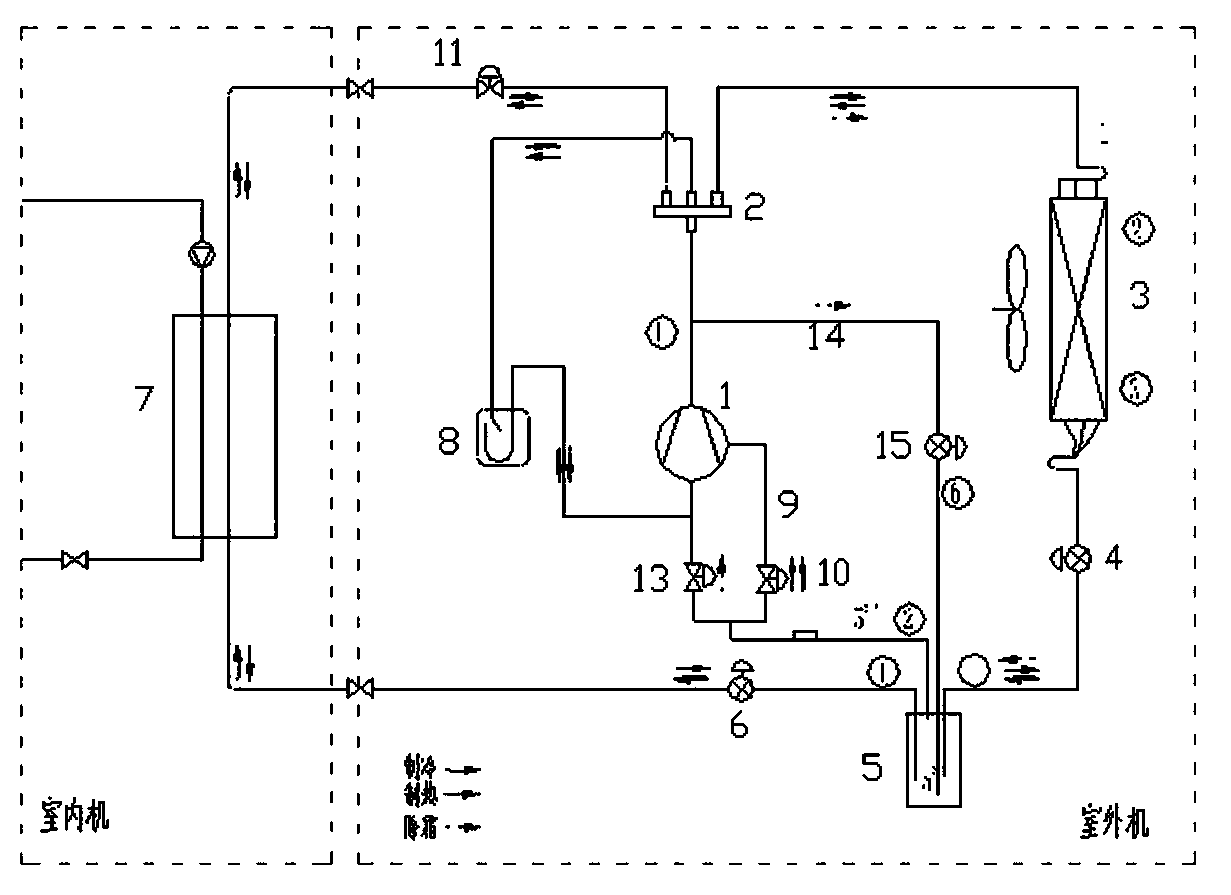

[0017] figure 1 It is a schematic diagram of an existing two-stage compressed air source heat pump circulation system. The system includes: a compressor 1, a four-way valve 2, an outdoor heat exchanger 3, a first expansion valve 4, a flash evaporator 5, a second expansion valve 6, an indoor heat exchanger 7 and a vapor-liquid separator, which are sequentially connected by pipelines 8. The compressor adopts a two-stage compressor. The flash evaporator has 3 ports, one inlet and two outlets. The upper end of the flash evaporator leads to a gas supply pipeline 9 connected with the high-pressure chamber of the compressor and is controlled by the third solenoid valve 10 . The system uses a refrigeration cycle during defrosting, and the system needs to absorb heat from the indoor medium, resulting in reduced comfort, and the indoor heat exchanger will fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com