Connector

A technology of connectors and connecting parts, which is applied in the direction of connection, parts and contact parts of connecting devices, etc., can solve the problems of occupation, large size of connectors, and large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

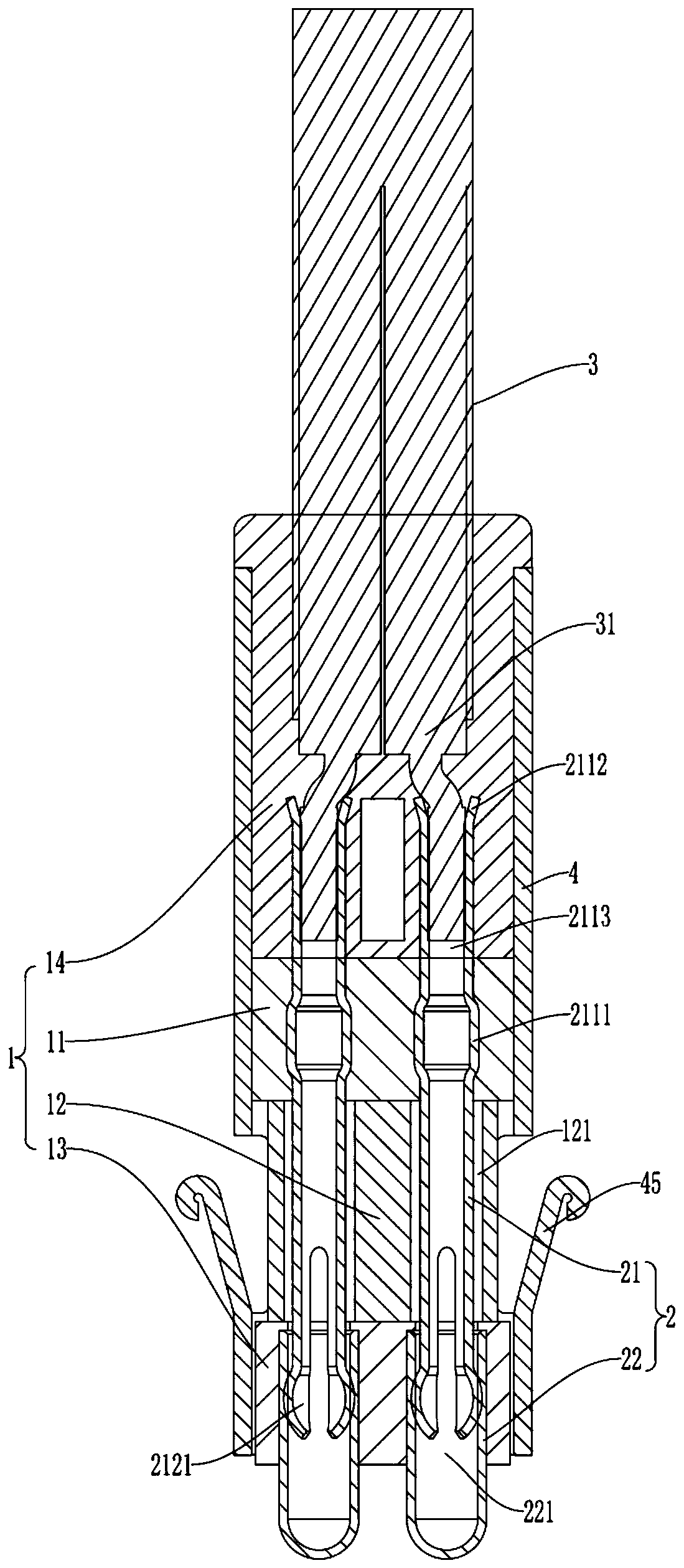

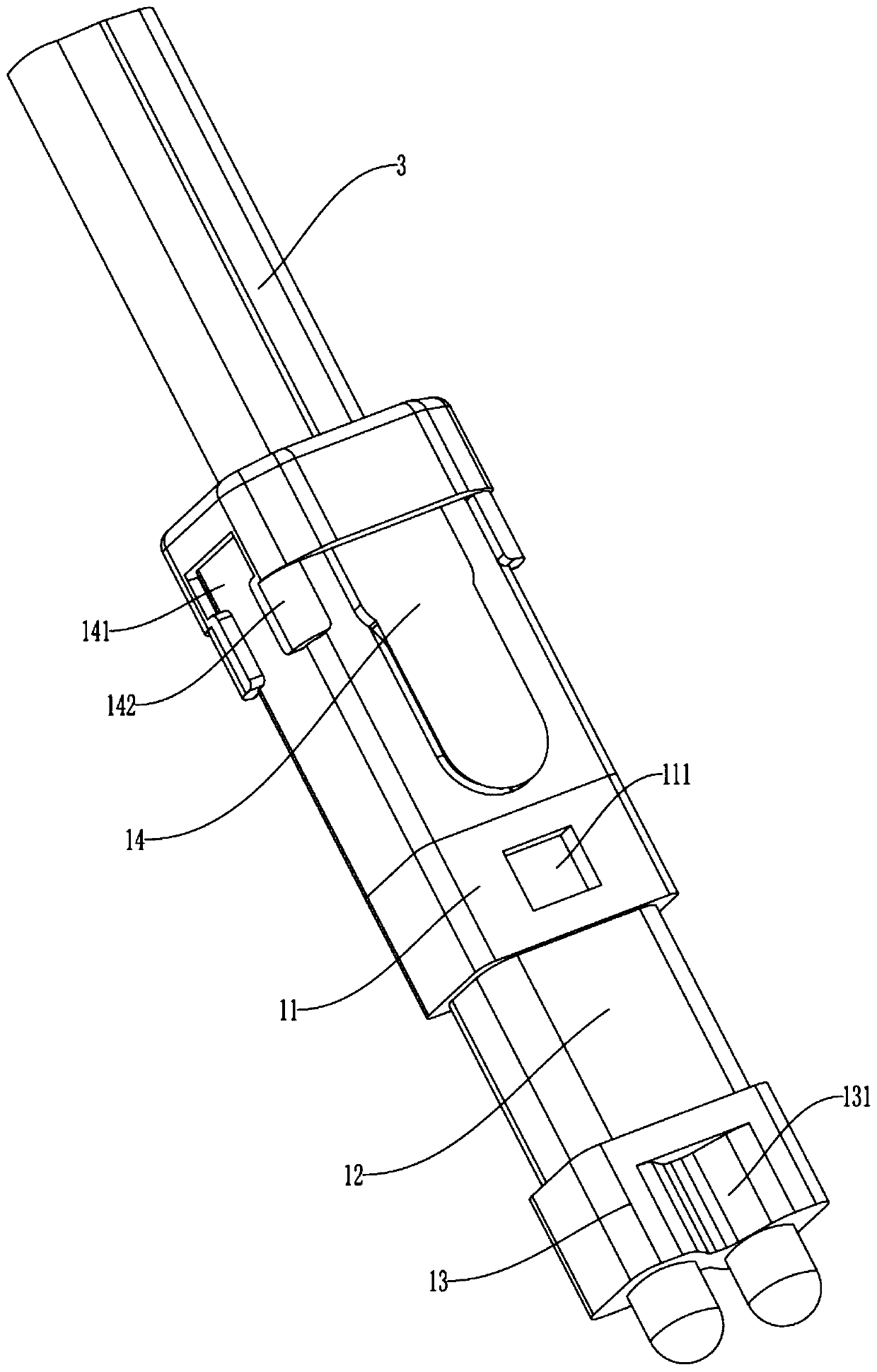

[0045] Such as Figure 1-3As shown, the connector includes an insulating body assembly 1 and a plurality of terminal assemblies 2 arranged side by side. Preferably, the number of terminal assemblies 2 in this embodiment is two. The terminal assembly 2 includes a connecting terminal 21 and a contact terminal 22. The connecting terminal 21 is arranged in the insulating body assembly 1, the tail end of the contact terminal 22 is arranged in the insulating body assembly 1, and the front end is exposed to the insulating body assembly 1. The contact terminal 22 The tail portion is provided with a receiving hole 221 , the contact terminal 22 is sleeved on the front end of the connecting terminal 21 , and the length of the sleeve is adjustable, and the front end of the connecting terminal 21 elastically contacts with the inner wall of the receiving hole 221 .

[0046] The front end of the connection terminal 21 is in elastic contact with the inner wall of the receiving hole 221, so t...

Embodiment 2

[0056] This embodiment provides a connector whose structure is basically the same as that of Embodiment 1, except for the structure of the connecting terminal.

[0057] Such as Figure 7 As shown, the connection terminal 21 is in the shape of a strip, and is bent at the part located in the first insulating block 11, forming a bent portion 2114, which is located in the first insulating block 11, so as to avoid the connection terminal 21 Dislocation movement occurs with the first insulating block 11 . The front end of the connecting terminal 21 is punched to form an elliptical through hole, and the major axis of the ellipse is located in the longitudinal direction of the connecting terminal 21 . Parts of the connecting terminal 21 located on both sides of the through hole protrude outward to form contact protrusions 2121 . When the front end of the connection terminal 21 extends into the contact terminal 22, the two contact protrusions 2121 will be drawn inward, and the two co...

Embodiment 3

[0059] This embodiment provides a connector whose structure is basically the same as that of Embodiment 1, except for the structure of the connecting terminal.

[0060] Such as Figure 8 As shown, the connection terminal 21 is in the shape of a strip, and is bent at the part located in the first insulating block 11, forming a bent portion 2114, which is located in the first insulating block 11, so as to avoid the connection terminal 21 Dislocation movement occurs with the first insulating block 11 .

[0061] In this embodiment, the elastic arms are two symmetrically arranged elastic rods 213 , and the contact protrusions 2121 are arranged outside the front ends of the elastic rods 213 . When the front end of the connection terminal 21 is inserted into the contact terminal 22 , the two contact protrusions 2121 abut against the inner wall of the contact terminal 22 , and the two elastic rods 213 are deformed to have a certain elastic force. The elastic rod 213 can ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com