Swirl trapped vortex type combustion chamber of micro-turbine engine

A technology for gas turbines and engines, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as shortened airflow retention time and reduced combustion performance of combustion chambers, and achieve reduced fuel consumption, improved combustion efficiency, and high-temperature areas The effect of reducing uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

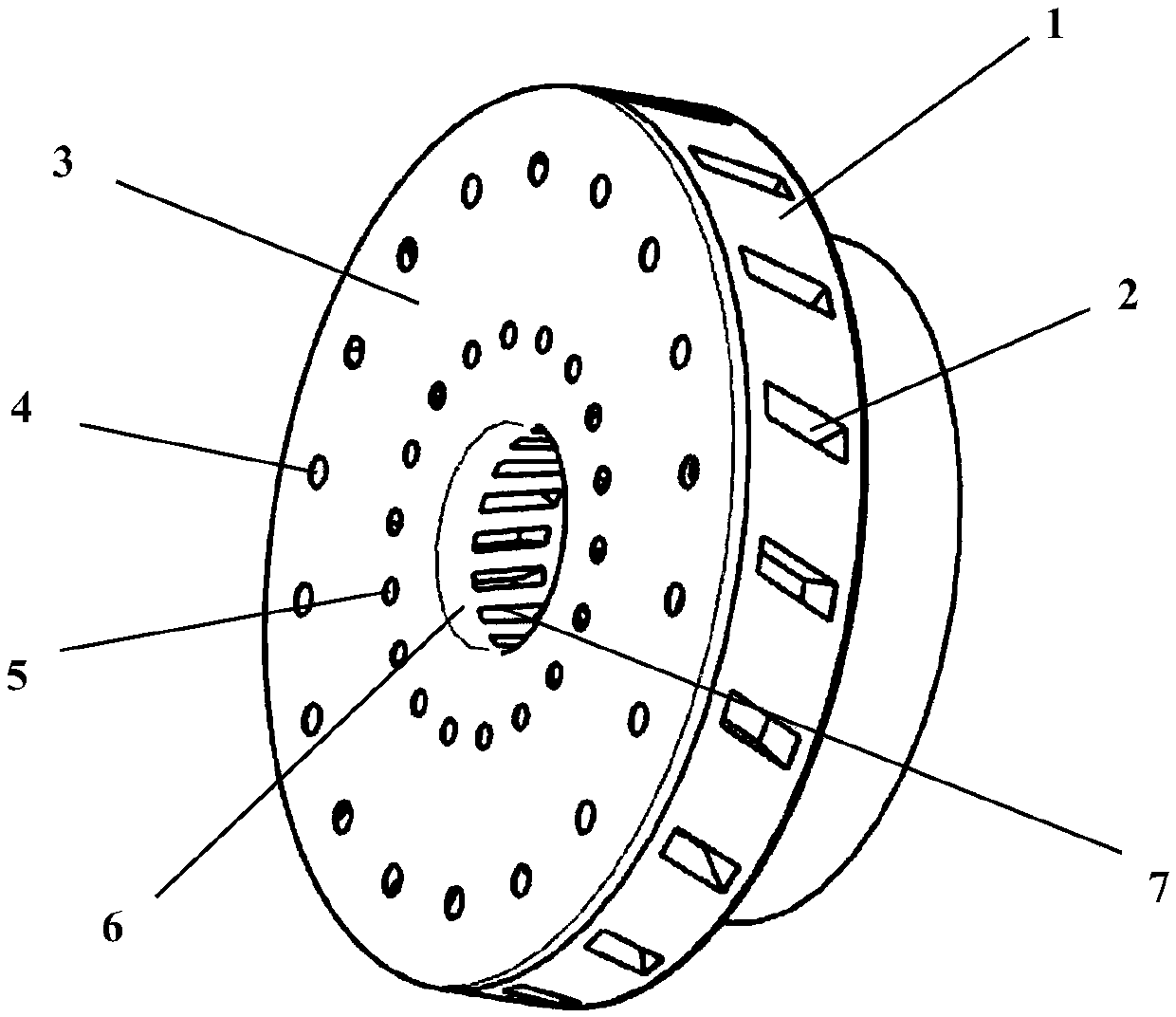

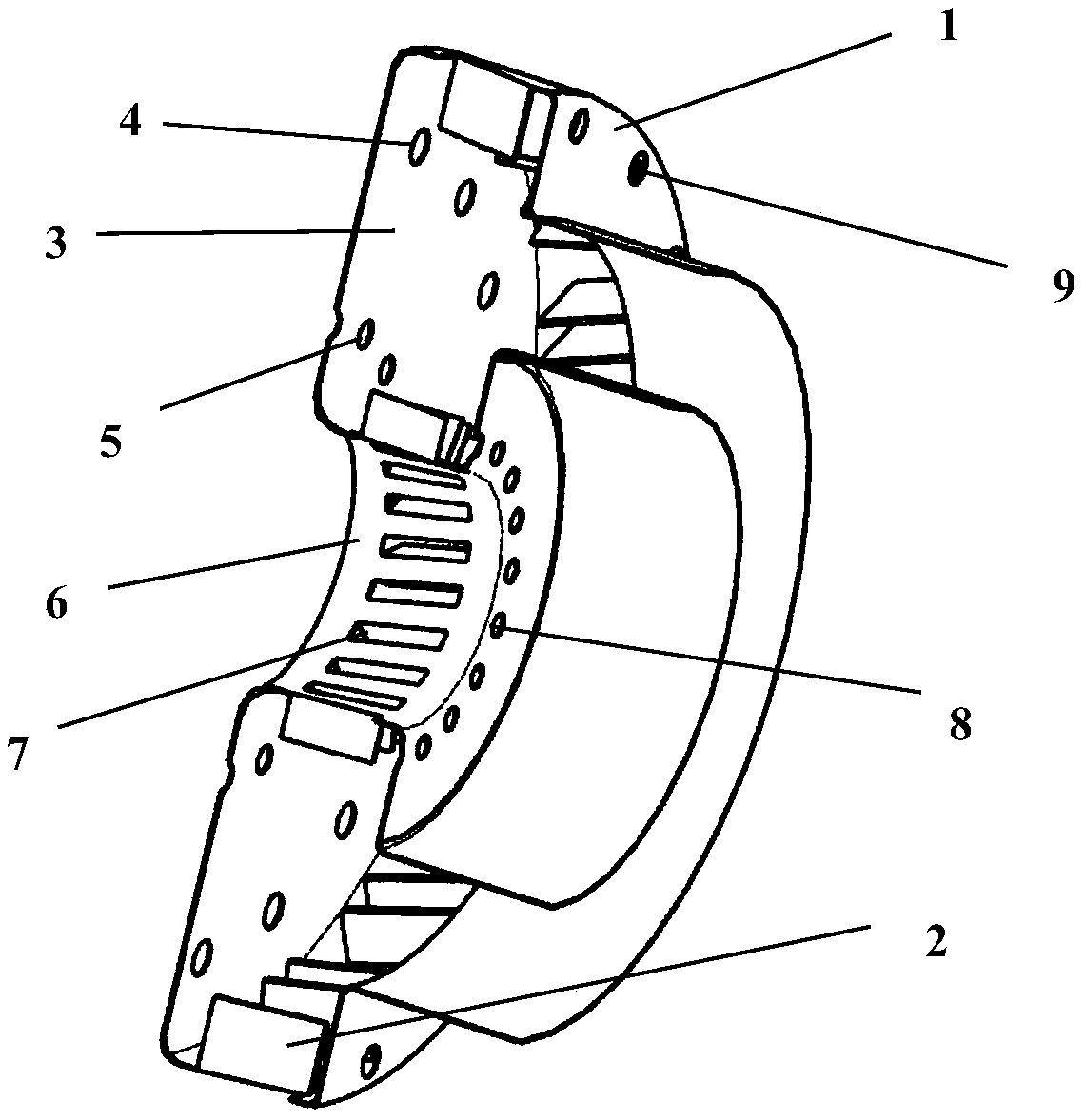

[0021] combine figure 1 , figure 2 , The invention provides a structure design of the combustion chamber of the swirling flow trapped vortex micro gas turbine engine that can effectively improve the combustion stability. figure 1 It is a structural schematic diagram of a swirl trapped vortex micro gas turbine engine combustor, figure 2 It is a cross-sectional schematic diagram of a swirl trapped vortex micro gas turbine engine combustor.

[0022] Such as figure 2 The air flow shown passes through 4-outer jet hole on the front wall, 5-inner jet hole on the front wall, 8-jet hole on the inner wall, 9-jet hole on the outer wall, 2-radial cyclone on the outer wall, 7-radial swirl on the inner wall The swirler enters the combustion chamber. The airflow entered by the jet hole outside the 4-front wall and the jet hole 9-the outer wall forms a stable axial recirculation zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com