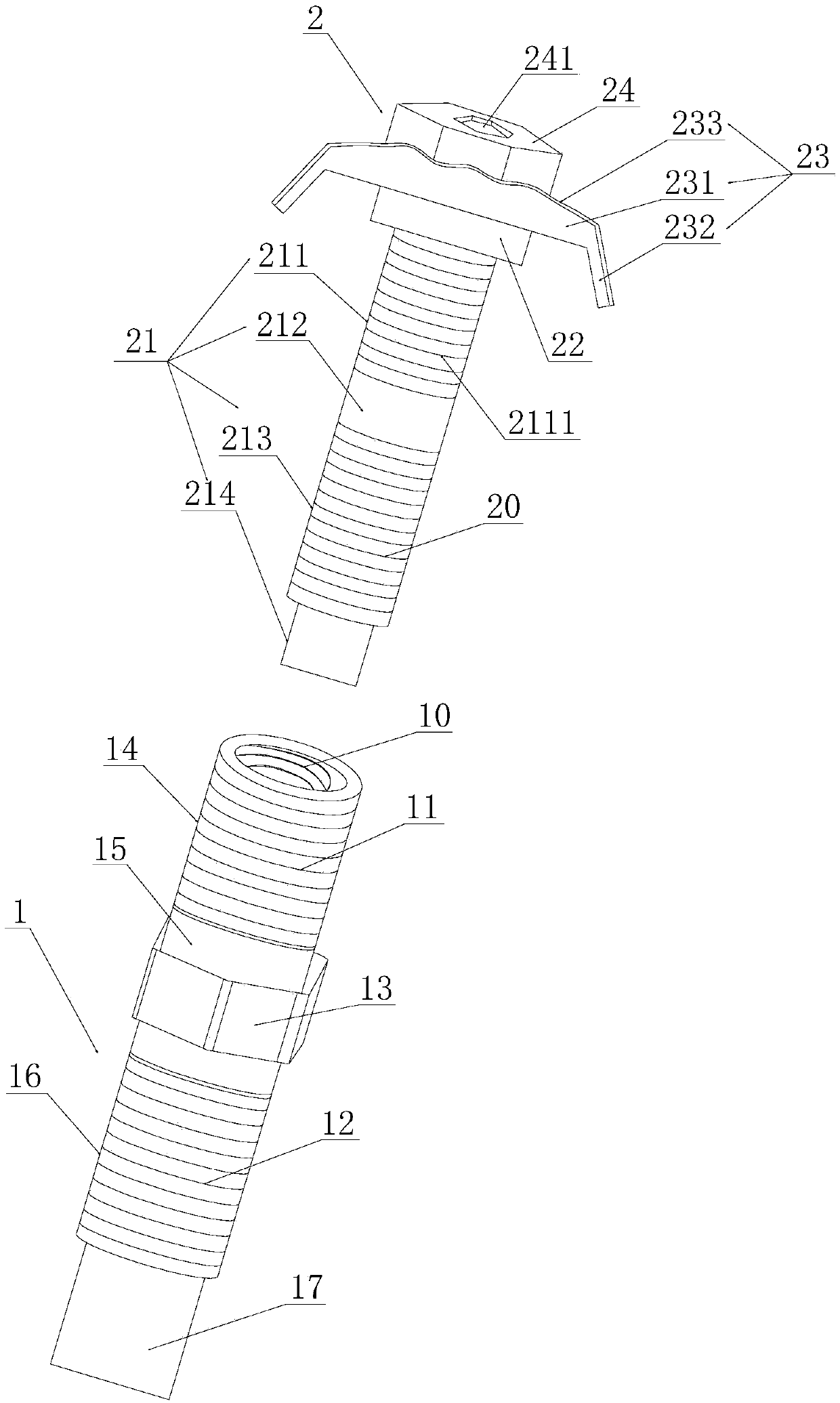

Combined type bolt for car hub

A combined bolt and car wheel technology, applied in bolts, screws, nuts and other directions, can solve the problems of insufficient operator experience, affecting the service life of bolts, increasing maintenance and replacement costs, etc., to achieve wide adaptability, flexible and convenient installation and disassembly, The effect of improving waterproof and rust-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

[0018] refer to figure 1 , the embodiment of the present invention provides a combined bolt for automobile hub, including a lower bolt part 1 and an upper bolt part 2, the inner wall of the lower bolt part 1 is provided with a connecting internal thread 10, and the upper bolt part 2 There is a connecting external thread 20 on it, and the connecting internal thread 10 and the connecting extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com